穿孔是不銹鋼管生產的重要工序之一,對不(bu)銹鋼管的管坯成本、品種規格及成品質量有很大影響。根據穿孔機的結構和穿孔過程變形特點的不同,穿孔機可分為兩大類:一類為斜軋穿孔機,又根據軋輥形狀及導衛裝置的不同而演變出多種類型,如曼乃斯曼穿孔機、狄塞爾穿孔機等;另一類是壓力擠孔機和推軋穿孔機(PPM穿孔機)。目前應用最廣的是二輥斜軋穿孔機。

一、斜(xie)軋穿孔

自1885年發明(ming)二(er)輥斜軋(ya)穿(chuan)(chuan)孔機(ji)(ji)(ji)以來,斜軋(ya)穿(chuan)(chuan)孔至今仍是(shi)最廣(guang)泛應用(yong)的(de)穿(chuan)(chuan)孔設備。主要斜軋(ya)穿(chuan)(chuan)孔機(ji)(ji)(ji)的(de)類型有:桶形(xing)輥穿(chuan)(chuan)孔機(ji)(ji)(ji)、狄(di)塞爾穿(chuan)(chuan)孔機(ji)(ji)(ji)、錐形(xing)輥穿(chuan)(chuan)孔機(ji)(ji)(ji)及三輥穿(chuan)(chuan)孔機(ji)(ji)(ji)。

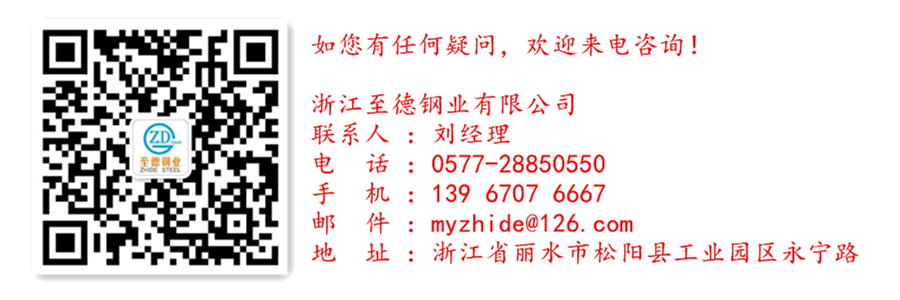

1. 桶形輥穿孔(kong)機

二輥斜軋(ya)穿(chuan)(chuan)孔(kong)機(ji)由(you)德國的(de)(de)曼乃斯曼(R.&M.Mannesmann)兄弟發明(ming),經瑞士工程師斯蒂弗(fu)爾(R.C Stiefeil)加以完善。它的(de)(de)工作運(yun)動(dong)(dong)情況如圖3-1所示,左(zuo)右兩個(ge)軋(ya)輥同向(xiang)旋(xuan)轉,上下(xia)垂直(zhi)(zhi)布置(zhi)的(de)(de)兩個(ge)導板固(gu)定不(bu)動(dong)(dong),中間(jian)一個(ge)隨動(dong)(dong)頂頭,軋(ya)輥軸線和(he)(he)軋(ya)制(zhi)線相交成一個(ge)傾斜角。軋(ya)輥左(zuo)右布置(zhi),導板上下(xia)布置(zhi)的(de)(de)為(wei)臥式(shi)穿(chuan)(chuan)孔(kong)機(ji),相反為(wei)立式(shi)穿(chuan)(chuan)孔(kong)機(ji)。二輥斜軋(ya)穿(chuan)(chuan)孔(kong)方(fang)法的(de)(de)優點是對心性好(hao),毛管(guan)(guan)的(de)(de)壁厚較(jiao)(jiao)均勻(yun);一次延(yan)伸系數較(jiao)(jiao)大(da),一般在(zai)1.25~4.5之間(jian),可以直(zhi)(zhi)接從實心圓坯穿(chuan)(chuan)制(zhi)成較(jiao)(jiao)薄的(de)(de)毛管(guan)(guan)。主要缺(que)點是這種(zhong)加工方(fang)法變形(xing)復雜(za),容易在(zai)毛管(guan)(guan)內外表面(mian)產(chan)生(sheng)和(he)(he)擴大(da)缺(que)陷(xian),所以對管(guan)(guan)坯質量要求較(jiao)(jiao)高,一般皆采用(yong)鍛、軋(ya)坯。由(you)于對鋼管(guan)(guan)表面(mian)質量要求的(de)(de)不(bu)斷提(ti)高,合金鋼比重的(de)(de)不(bu)斷增長,尤(you)其(qi)是連(lian)鑄圓坯的(de)(de)推廣(guang)使用(yong),現在(zai)這種(zhong)喂入角小于13°的(de)(de)二輥斜軋(ya)機(ji),已不(bu)能滿足不(bu)銹(xiu)鋼管(guan)(guan)生(sheng)產(chan)中對生(sheng)產(chan)率和(he)(he)鋼管(guan)(guan)質量的(de)(de)要求,因而新結構的(de)(de)斜軋(ya)穿(chuan)(chuan)孔(kong)機(ji)相繼出現。

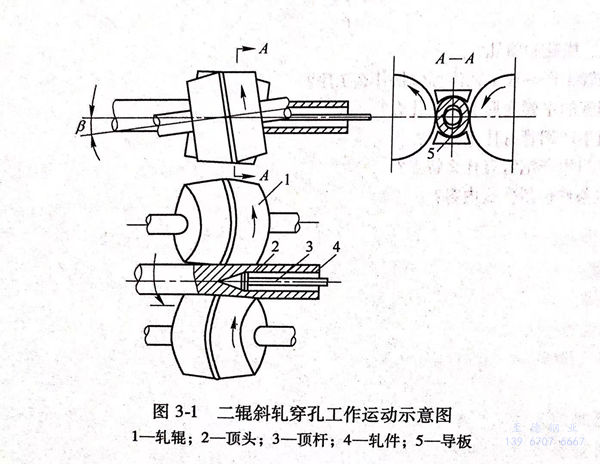

2. 狄塞(sai)爾(er)穿孔機

狄塞爾穿孔機是主動旋轉導盤二輥桶形輥斜軋穿孔機,如圖3-2所示,1972年開始見于聯邦德國,是在二輥桶形輥穿孔機基礎上演變而來的。軋輥上下布置,每個軋輥由單獨的主電機通過萬向連接軸直接驅動;左右兩側的導板被兩主動旋轉導盤所替代,因導盤是傳動的,導盤旋轉的切線速度在變形區壓縮帶比軋輥切線速度在軋制軸線上的分量大20%~25%,給軋件施加一個軸向送進力,以減少軋件的軸向阻力。孔喉橢圓度可調近1.0,這樣使最大延伸系數達到5.0,軸向金屬滑動系數增加,毛管內外表面質量大為改善,從而提高了生產率,降低了單位能耗。狄塞爾穿孔機出口速度達1.2m/s,導盤磨損小,使用壽命長,不必經常更換,有利于作業率的提高。

圍繞提(ti)(ti)高穿(chuan)孔效率和穿(chuan)孔毛(mao)(mao)管(guan)精度,進(jin)行了(le)一(yi)系列的(de)技術改進(jin)。如頂桿采用線外(wai)(wai)循(xun)(xun)環冷卻(que),在(zai)機架出(chu)口,向(xiang)一(yi)側循(xun)(xun)環運(yun)送(song)冷卻(que),冷卻(que)后送(song)回穿(chuan)孔軋制線,由于是線外(wai)(wai)脫(tuo)出(chu)穿(chuan)孔毛(mao)(mao)管(guan)送(song)往(wang)下道工序(xu),避免了(le)頂桿小車(che)的(de)往(wang)復運(yun)動,縮短穿(chuan)孔周期,提(ti)(ti)高了(le)效率。如機后采用多組定心抱輥,增加(jia)頂桿的(de)穩(wen)定性,提(ti)(ti)高壁厚精度。

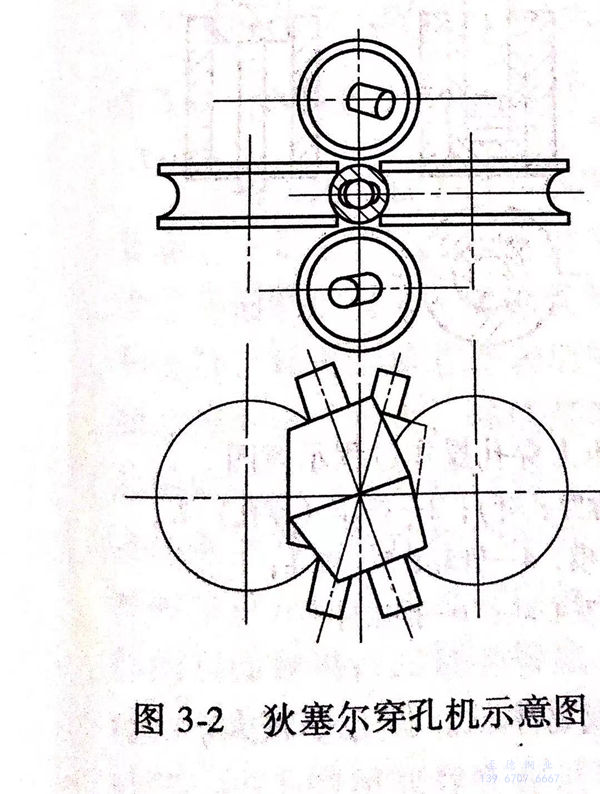

3. 錐(zhui)形輥穿孔機(ji)

20世紀80年代又在(zai)狄塞爾穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)結(jie)構特點(dian)的(de)(de)(de)(de)基(ji)礎上(shang)(shang),出現了主(zhu)動(dong)旋(xuan)轉(zhuan)導(dao)盤(pan)、大(da)喂入角的(de)(de)(de)(de)錐形(xing)(xing)(xing)(xing)輥(gun)(gun)兩(liang)輥(gun)(gun)斜軋(ya)(ya)(ya)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji),如圖3-3所示。它與(yu)狄塞爾穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)最(zui)大(da)的(de)(de)(de)(de)不同是軋(ya)(ya)(ya)輥(gun)(gun)的(de)(de)(de)(de)形(xing)(xing)(xing)(xing)狀(zhuang)由桶(tong)形(xing)(xing)(xing)(xing)改為(wei)錐形(xing)(xing)(xing)(xing),這(zhe)(zhe)種(zhong)輥(gun)(gun)形(xing)(xing)(xing)(xing)對斜軋(ya)(ya)(ya)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)的(de)(de)(de)(de)適應(ying)(ying)性來(lai)說,優(you)于桶(tong)形(xing)(xing)(xing)(xing)輥(gun)(gun)。因為(wei)在(zai)這(zhe)(zhe)種(zhong)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)上(shang)(shang),錐形(xing)(xing)(xing)(xing)輥(gun)(gun)的(de)(de)(de)(de)直徑沿穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)變形(xing)(xing)(xing)(xing)區是逐(zhu)漸增加(jia)的(de)(de)(de)(de),因此,在(zai)很(hen)大(da)程度上(shang)(shang)減(jian)(jian)少管(guan)坯(pi)變形(xing)(xing)(xing)(xing)過(guo)程中(zhong)的(de)(de)(de)(de)切向(xiang)剪切應(ying)(ying)力,抑制旋(xuan)轉(zhuan)橫鍛效應(ying)(ying),改善了毛(mao)管(guan)內(nei)外表(biao)面質量(liang),使得許多難穿(chuan)(chuan)(chuan)(chuan)的(de)(de)(de)(de)高(gao)(gao)合(he)金鋼(gang)管(guan)坯(pi)都可以在(zai)這(zhe)(zhe)種(zhong)軋(ya)(ya)(ya)機(ji)上(shang)(shang)順利軋(ya)(ya)(ya)制。錐形(xing)(xing)(xing)(xing)輥(gun)(gun)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)效率高(gao)(gao),有(you)報道稱最(zui)大(da)出口速(su)度可達1.5m/s,有(you)利于高(gao)(gao)生產率機(ji)組選用;軋(ya)(ya)(ya)輥(gun)(gun)軸(zhou)線與(yu)軋(ya)(ya)(ya)制線間(jian)除了有(you)10°左(zuo)右的(de)(de)(de)(de)喂入角α外,還(huan)有(you)一個15°左(zuo)右的(de)(de)(de)(de)輾軋(ya)(ya)(ya)角γ,這(zhe)(zhe)樣(yang)可使該類(lei)型穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)軸(zhou)向(xiang)滑動(dong)系(xi)數達到了0.9,最(zui)大(da)延伸系(xi)數可達6.0,在(zai)變形(xing)(xing)(xing)(xing)量(liang)的(de)(de)(de)(de)分配上(shang)(shang),可承擔(dan)較(jiao)大(da)變形(xing)(xing)(xing)(xing),從而減(jian)(jian)少了軋(ya)(ya)(ya)管(guan)機(ji)的(de)(de)(de)(de)變形(xing)(xing)(xing)(xing);穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)擴徑量(liang)達到30%~40%,這(zhe)(zhe)就不僅(jin)可提(ti)供薄壁毛(mao)管(guan),還(huan)可以減(jian)(jian)少管(guan)坯(pi)規格(ge)范圍,簡(jian)化生產管(guan)理。錐形(xing)(xing)(xing)(xing)輥(gun)(gun)穿(chuan)(chuan)(chuan)(chuan)孔(kong)(kong)(kong)機(ji)既有(you)配備導(dao)盤(pan)的(de)(de)(de)(de),也有(you)配備導(dao)板的(de)(de)(de)(de),目(mu)前已建、在(zai)建新(xin)的(de)(de)(de)(de)軋(ya)(ya)(ya)管(guan)機(ji)組上(shang)(shang)兩(liang)種(zhong)配置(zhi)均(jun)有(you)使用。

狄塞(sai)爾(er)穿(chuan)(chuan)(chuan)孔機(ji)和錐形輥(gun)穿(chuan)(chuan)(chuan)孔機(ji)都是當代廣為(wei)采用的新型穿(chuan)(chuan)(chuan)孔機(ji),穿(chuan)(chuan)(chuan)孔效率高及產品精度高,適(shi)于連鑄(zhu)坯穿(chuan)(chuan)(chuan)孔。其中錐形輥(gun)穿(chuan)(chuan)(chuan)孔機(ji)具(ju)有更(geng)大的發展前(qian)途(tu)。

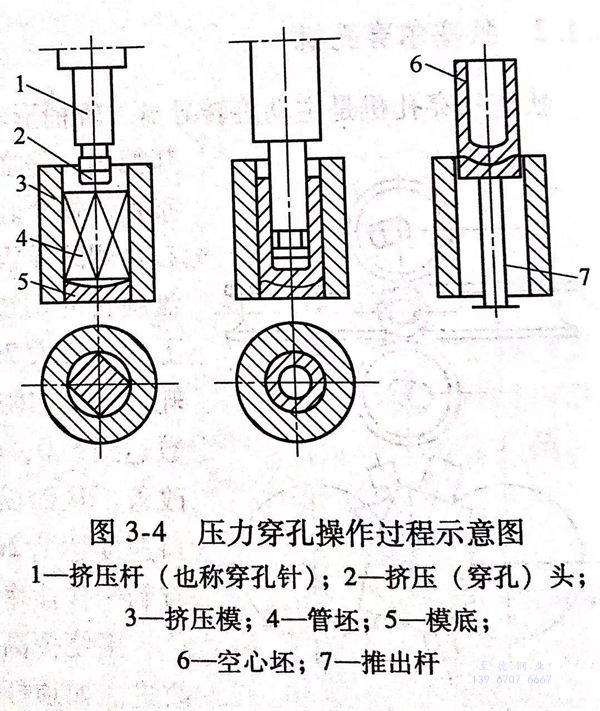

二、壓力(li)穿孔

不銹鋼(gang)管(guan)坯壓力穿孔常在立式水壓機或液壓機(穿孔機)上進行,圖3-4為壓力穿孔(也稱壓力沖孔)操作過程示意圖。壓力穿孔于1891年問世,它是將方形或多邊形鋼錠放在擠壓缸中,擠成中空杯體,延伸系數為1.0~1.1,穿孔比(空心坯長度與內徑比)不大于7~10。

與(yu)二輥斜軋相比(bi),這(zhe)種加工(gong)方法的(de)(de)(de)坯(pi)料中(zhong)(zhong)心(xin)(xin)(xin)處于不(bu)等(deng)軸全向壓應力(li)狀態,外表面(mian)承受著較大的(de)(de)(de)徑向壓力(li),因內、外表面(mian)在加工(gong)過(guo)程中(zhong)(zhong)不(bu)會產生(sheng)缺(que)(que)陷,對來料沒有苛刻要求(qiu),可用(yong)于鋼(gang)錠、連鑄方坯(pi)和低塑性材料的(de)(de)(de)穿(chuan)孔。此法加工(gong)主(zhu)要是中(zhong)(zhong)心(xin)(xin)(xin)變形,特別有利于鋼(gang)錠中(zhong)(zhong)心(xin)(xin)(xin)的(de)(de)(de)粗大疏松組織致密(mi)化,雖然最大延伸系數(shu)只有1.1,但中(zhong)(zhong)心(xin)(xin)(xin)部分(fen)的(de)(de)(de)變形效果相當于外部加工(gong)效果的(de)(de)(de)5倍。主(zhu)要缺(que)(que)點(dian)是生(sheng)產率低,成材率低,偏(pian)心(xin)(xin)(xin)率較大。

三(san)、對穿孔毛管的質量要(yao)求

1. 對穿孔工(gong)藝(yi)要(yao)求

不銹鋼管(guan)坯穿(chuan)(chuan)孔(kong)(kong)是熱軋無縫鋼管(guan)生(sheng)產中最(zui)重要的(de)變形工(gong)序之(zhi)一,它將(jiang)實心(xin)的(de)管(guan)坯變為(wei)空心(xin)坯,穿(chuan)(chuan)孔(kong)(kong)后(hou)的(de)空心(xin)坯通常(chang)被稱作毛(mao)管(guan)。我們(men)可以視穿(chuan)(chuan)孔(kong)(kong)工(gong)序為(wei)定(ding)(ding)型(xing)工(gong)序,即將(jiang)軋件的(de)橫截面(mian)定(ding)(ding)為(wei)圓環狀的(de)工(gong)序。穿(chuan)(chuan)孔(kong)(kong)后(hou)毛(mao)管(guan)質(zhi)量(liang)的(de)好壞直(zhi)接關系(xi)到下道工(gong)序的(de)工(gong)藝是否能正常(chang)執行(xing)以及最(zui)終(zhong)產品質(zhi)量(liang)的(de)高低。為(wei)此對穿(chuan)(chuan)孔(kong)(kong)工(gong)藝提出如下幾點要求:首先要保證穿(chuan)(chuan)制的(de)毛(mao)管(guan)壁厚均勻,螺旋線較淺、橢(tuo)圓度(du)(du)小(xiao),幾何尺寸(cun)精度(du)(du)高,當毛(mao)管(guan)尺寸(cun)偏小(xiao)、芯棒同(tong)毛(mao)管(guan)間隙過小(xiao)時,毛(mao)管(guan)的(de)溫降快,軋制過程(cheng)中容(rong)易產生(sheng)壁厚不均、拉凹、孔(kong)(kong)洞等缺陷;其次,毛(mao)管(guan)的(de)內(nei)外表(biao)面(mian)要光滑(hua),不得有(you)結疤、折疊、劃(hua)傷(shang)、裂紋、凹凸不平等缺陷;最(zui)后(hou)要有(you)相應的(de)穿(chuan)(chuan)孔(kong)(kong)速度(du)(du)和軋制周期,以適應整個機(ji)組(zu)的(de)生(sheng)產節奏(zou),使(shi)毛(mao)管(guan)溫度(du)(du)比(bi)較均勻、終(zhong)軋溫度(du)(du)能夠滿足軋管(guan)機(ji)的(de)工(gong)藝要求。

2. 確保毛管質量的技術措施

為(wei)了(le)(le)滿足上述工藝要求,除了(le)(le)確(que)定(ding)正確(que)的穿孔工藝參(can)數(包(bao)括管坯(pi)加(jia)熱溫(wen)度、穿孔溫(wen)度、穿孔速度、軋(ya)輥轉速和喂入(ru)角的大(da)小)及調整(zheng)參(can)數(輥距、導板/導盤距、頂頭前伸(shen)量)外,穿孔機組還應(ying)用了(le)(le)如下技術:

a. 穿(chuan)孔機(ji)架:軋輥(gun)垂直布置,使得(de)更換和檢(jian)查(cha)導盤/導板的時間(jian)很短,可確保毛管外表面(mian)質量;

b. 出口部分:頂(ding)(ding)(ding)(ding)(ding)頭(tou)/頂(ding)(ding)(ding)(ding)(ding)桿(gan)從毛管中抽出后(hou)頂(ding)(ding)(ding)(ding)(ding)頭(tou)或(huo)頂(ding)(ding)(ding)(ding)(ding)頭(tou)/頂(ding)(ding)(ding)(ding)(ding)桿(gan)的冷卻(que)在線外(wai)(wai)(wai)進(jin)行(xing)。設置頂(ding)(ding)(ding)(ding)(ding)頭(tou)或(huo)頂(ding)(ding)(ding)(ding)(ding)頭(tou)/頂(ding)(ding)(ding)(ding)(ding)桿(gan)線外(wai)(wai)(wai)冷卻(que)循環系統,可縮短周期時(shi)間,更容易檢查、更換(huan)頂(ding)(ding)(ding)(ding)(ding)頭(tou),另外(wai)(wai)(wai)如采用線外(wai)(wai)(wai)用回轉式冷卻(que)裝置進(jin)行(xing)頂(ding)(ding)(ding)(ding)(ding)桿(gan)(帶頂(ding)(ding)(ding)(ding)(ding)頭(tou))冷卻(que),還可確(que)保(bao)頂(ding)(ding)(ding)(ding)(ding)桿(gan)的直度較好,為(wei)毛管的壁厚均勻提(ti)供了保(bao)證;頂(ding)(ding)(ding)(ding)(ding)頭(tou)的循環使(shi)用,因(yin)冷卻(que)時(shi)間充分,使(shi)冷卻(que)效果得到保(bao)證,從而可以提(ti)高頂(ding)(ding)(ding)(ding)(ding)頭(tou)的使(shi)用壽(shou)命,確(que)保(bao)毛管內(nei)表面的光滑;

c. 頂(ding)(ding)(ding)桿及毛(mao)管導(dao)向(xiang):有多(duo)組定心輥(gun)(gun),第一組定心輥(gun)(gun)裝在(zai)機架內,使(shi)其盡量靠近穿(chuan)(chuan)孔(kong)變形區,以減小頂(ding)(ding)(ding)頭(tou)/頂(ding)(ding)(ding)桿的懸臂長度(du)、提高(gao)頂(ding)(ding)(ding)桿的剛度(du),可更(geng)好(hao)地限制頂(ding)(ding)(ding)桿/頂(ding)(ding)(ding)頭(tou)及軋件在(zai)穿(chuan)(chuan)孔(kong)過程中的徑向(xiang)抖動,確保穿(chuan)(chuan)出的毛(mao)管壁(bi)厚均勻;

d. 采用頂桿(gan)預(yu)旋轉(zhuan)(zhuan)技術(shu),頂頭(tou)能自動對正(zheng)管坯的(de)中心,以提高(gao)毛管頭(tou)部的(de)壁厚精度,并(bing)可降低二次(ci)咬入(ru)(ru)時因頂頭(tou)/頂桿(gan)轉(zhuan)(zhuan)動慣量的(de)阻(zu)力轉(zhuan)(zhuan)矩而發(fa)生不咬入(ru)(ru)(前卡)故障的(de)概率。

3. 特(te)殊的工藝要(yao)求

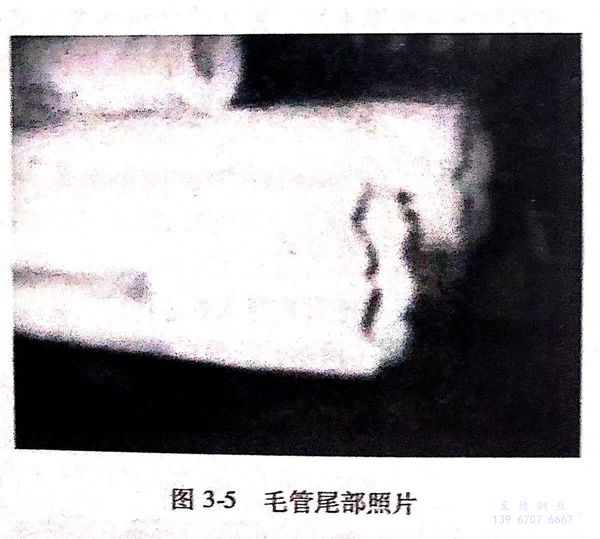

為滿足連(lian)軋(ya)管(guan)工藝的(de)(de)(de)特殊性,對于(yu)專供連(lian)續(xu)軋(ya)管(guan)機使用(yong)的(de)(de)(de)毛(mao)(mao)(mao)管(guan),還(huan)有兩項重要的(de)(de)(de)質量指標要求:一(yi)是(shi)毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)的(de)(de)(de)橢圓度(du)要小,因為毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)橢圓度(du)過(guo)大將(jiang)(jiang)影響軋(ya)管(guan)前穿芯(xin)(xin)棒(bang)的(de)(de)(de)順(shun)利進(jin)行,輕者(zhe)刮(gua)掉(diao)芯(xin)(xin)棒(bang)表面(mian)(mian)的(de)(de)(de)潤(run)滑劑,使軋(ya)制過(guo)程(cheng)中(zhong)震動較大,降低(di)荒管(guan)的(de)(de)(de)壁厚精度(du)和芯(xin)(xin)棒(bang)的(de)(de)(de)使用(yong)壽命(ming)并損傷(shang)設備,重者(zhe)芯(xin)(xin)棒(bang)可能會(hui)頂彎毛(mao)(mao)(mao)管(guan),致使生產中(zhong)斷,這(zhe)就要求在調整時(shi)注(zhu)意保證(zheng)穿孔過(guo)程(cheng)即將(jiang)(jiang)結(jie)束時(shi),毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)的(de)(de)(de)歸圓效果;二是(shi)毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)不得存在尾部(bu)(bu)鐮刀(非(fei)環狀連(lian)續(xu)體部(bu)(bu)分的(de)(de)(de)俗稱,見(jian)圖3-5)缺(que)陷,當毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)存在尾部(bu)(bu)鐮刀缺(que)陷時(shi),穿芯(xin)(xin)棒(bang)過(guo)程(cheng)中(zhong)容易將(jiang)(jiang)毛(mao)(mao)(mao)管(guan)尾部(bu)(bu)不連(lian)續(xu)的(de)(de)(de)部(bu)(bu)分金(jin)屬(shu)碰掉(diao),一(yi)旦這(zhe)些(xie)溫度(du)較低(di)的(de)(de)(de)金(jin)屬(shu)被帶到毛(mao)(mao)(mao)管(guan)中(zhong),軋(ya)制時(shi)將(jiang)(jiang)硌傷(shang)軋(ya)件(jian)而產生孔洞管(guan),若(ruo)這(zhe)些(xie)較硬的(de)(de)(de)金(jin)屬(shu)掉(diao)在軋(ya)輥上,將(jiang)(jiang)硌傷(shang)軋(ya)輥輥面(mian)(mian)而造(zao)成鋼管(guan)外表面(mian)(mian)缺(que)陷等(deng)嚴重的(de)(de)(de)質量事故(gu)。

如(ru)果是向(xiang)限動(dong)芯(xin)棒(bang)連(lian)續軋(ya)管(guan)(guan)(guan)機(ji)提(ti)供毛(mao)(mao)管(guan)(guan)(guan),還(huan)須向(xiang)毛(mao)(mao)管(guan)(guan)(guan)內(nei)噴(pen)吹(chui)氮氣和硼(peng)(peng)(peng)砂,以起到(dao)去除毛(mao)(mao)管(guan)(guan)(guan)內(nei)表(biao)面(mian)的(de)(de)氧(yang)(yang)化(hua)鐵皮、減小芯(xin)棒(bang)與(yu)軋(ya)件間的(de)(de)摩擦力(li)、防止軋(ya)制(zhi)(zhi)過程中(zhong)抖動(dong)的(de)(de)作用。其過程為:抽出(chu)頂桿后的(de)(de)毛(mao)(mao)管(guan)(guan)(guan),送到(dao)吹(chui)硼(peng)(peng)(peng)砂站,由(you)一特制(zhi)(zhi)的(de)(de)噴(pen)嘴(zui)向(xiang)毛(mao)(mao)管(guan)(guan)(guan)內(nei)部噴(pen)入硼(peng)(peng)(peng)砂和氮氣,吹(chui)掉(diao)毛(mao)(mao)管(guan)(guan)(guan)內(nei)部的(de)(de)氧(yang)(yang)化(hua)鐵皮,清除原來(lai)的(de)(de)氧(yang)(yang)化(hua)物(wu)(硼(peng)(peng)(peng)砂使管(guan)(guan)(guan)內(nei)壁的(de)(de)氧(yang)(yang)化(hua)層脫氧(yang)(yang),高(gao)溫下的(de)(de)硼(peng)(peng)(peng)砂呈(cheng)熔(rong)融態,均勻地附(fu)著在(zai)毛(mao)(mao)管(guan)(guan)(guan)內(nei)表(biao)面(mian)上可起到(dao)潤滑劑的(de)(de)作用,氮氣能保(bao)持毛(mao)(mao)管(guan)(guan)(guan)內(nei)表(biao)面(mian)不(bu)再被氧(yang)(yang)化(hua));另外(wai),硼(peng)(peng)(peng)砂在(zai)高(gao)溫狀態下生(sheng)(sheng)成霧狀氣體,充滿(man)管(guan)(guan)(guan)內(nei),以防止在(zai)隨后的(de)(de)運動(dong)中(zhong)空氣進入,減少(shao)內(nei)表(biao)面(mian)產(chan)生(sheng)(sheng)二次氧(yang)(yang)化(hua)的(de)(de)可能。這就要求軋(ya)管(guan)(guan)(guan)前盡量避免(mian)毛(mao)(mao)管(guan)(guan)(guan)的(de)(de)軸向(xiang)移動(dong),以防止毛(mao)(mao)管(guan)(guan)(guan)內(nei)表(biao)面(mian)產(chan)生(sheng)(sheng)二次氧(yang)(yang)化(hua),從而確保(bao)軋(ya)制(zhi)(zhi)過程的(de)(de)穩定和軋(ya)出(chu)荒管(guan)(guan)(guan)的(de)(de)質(zhi)量。

限(xian)動芯棒連續軋(ya)管(guan)(guan)機組是否(fou)(fou)能正(zheng)常運轉(zhuan),是否(fou)(fou)能生產出高質(zhi)量(liang)(liang)(liang)的(de)不銹(xiu)鋼管(guan)(guan),與毛管(guan)(guan)的(de)各項(xiang)質(zhi)量(liang)(liang)(liang)指(zhi)標(包括(kuo)溫度(du)的(de)均勻性(xing)、外徑/壁厚幾何尺寸的(de)精度(du)、內外表面的(de)光滑程度(du)等(deng))有很大(da)關系特(te)別是與毛管(guan)(guan)尾部(bu)的(de)質(zhi)量(liang)(liang)(liang)狀況(kuang)(內徑尺寸偏(pian)差和是否(fou)(fou)存在(zai)尾部(bu)鐮刀)以及(ji)為清除毛管(guan)(guan)內表面氧(yang)化物、防止毛管(guan)(guan)內表面二次氧(yang)化所采取的(de)上述工藝措施的(de)效果(guo)是密切(qie)相關的(de)。