浙江至德鋼業有限公司銷售人員認為,影響不銹鋼管價格的因素除了品牌、材質和生產工藝以外,最重要因素是不(bu)銹鋼管表面處理方法。為進一步改善管道材料特性,對管道內外表面進行處理 般有四種方法:酸洗鈍化(AP)、機械拋光(MP)、光亮退火(BA)和電解拋光(EP)處理工藝。試驗資料和實踐都證明,通過表面處理后,管道材料的粗糙度減小,表面吸附性減弱。那么AP、MP、BP、EP級不銹鋼管的區別在哪?

AP(Acid Pickling)酸(suan)洗處理

不銹鋼的耐腐蝕能力主要來源于其內含的鉻元素與氧氣發生反應后在其表面形成一層致密的防護層。而酸洗的作用就是讓其提前發生這種反應,以提高不銹鋼管的耐腐蝕能力,酸洗過程中會去除管材表面所附著的油污及其他在生產中所沾染的其他物質。管道內外表面較粗糙易有懸浮雜質附著。

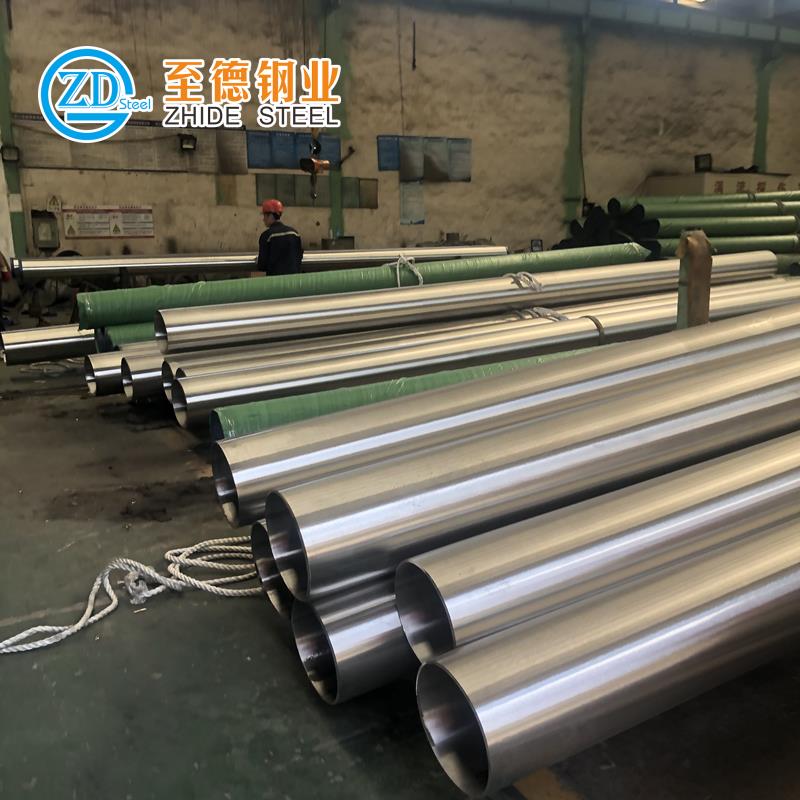

MP(Mechanical polishing)機械(xie)拋光

拋(pao)(pao)(pao)光(guang)輪或(huo)拋(pao)(pao)(pao)光(guang)帶借助拋(pao)(pao)(pao)光(guang)劑中的(de)磨(mo)(mo)料(liao)對不(bu)銹鋼管表面進行拋(pao)(pao)(pao)磨(mo)(mo)加(jia)(jia)工(gong),促使不(bu)銹鋼管面達(da)到平(ping)滑拋(pao)(pao)(pao)光(guang)效果(guo)。其(qi)亮度與效果(guo)則取決于加(jia)(jia)工(gong)方式的(de)種類。另外機(ji)械(xie)拋(pao)(pao)(pao)光(guang)后雖較美觀但也會降低抗蝕性,所以當用(yong)在腐蝕環境下需再經過鈍(dun)化處理(li),且(qie)鋼管表面常有拋(pao)(pao)(pao)光(guang)材料(liao)殘留。

The polishing wheel or polishing belt uses the abrasive in the polishing agent to polish the surface of the stainless steel tube to promote the smooth polishing effect of the stainless steel tube surface.Its brightness and effect depend on the type of processing method.In addition,although it is more beautiful after mechanical polishing,it will also reduce the corrosion resistance,so when it is used in a corrosive environment,it needs to be passivated again,and there are often polishing materials left on the surface of the steel pipe.

BA(Bright Annealing)光亮(liang)退火

不(bu)銹鋼(gang)(gang)管在制造過(guo)程中,用于(yu)潤(run)滑的(de)(de)(de)(de)油脂(zhi)晶粒也會(hui)因加工而變形,為了避免油脂(zhi)殘(can)留在鋼(gang)(gang)管中,在退火(huo)時利(li)用高溫以(yi)氫(qing)氣(qi)(qi)充(chong)當爐內氣(qi)(qi)氛(fen),借由氫(qing)氣(qi)(qi)與鋼(gang)(gang)管表(biao)面(mian)的(de)(de)(de)(de)碳氧(yang)結合燃燒,進一步清潔鋼(gang)(gang)管的(de)(de)(de)(de)表(biao)面(mian)產生亮(liang)面(mian)效果(guo),這種利(li)用純氫(qing)氣(qi)(qi)退火(huo)加熱(re)并(bing)快(kuai)速冷卻,以(yi)亮(liang)化(hua)光(guang)面(mian)的(de)(de)(de)(de)方式叫光(guang)輝退火(huo)。雖然(ran)利(li)用此種方式來亮(liang)化(hua)表(biao)面(mian)可保鋼(gang)(gang)管充(chong)分(fen)干凈無任何外來污染。但這種表(biao)面(mian)的(de)(de)(de)(de)明亮(liang)度若與其他拋光(guang)方式相較機械(xie)、化(hua)學、電解會(hui)有霧面(mian)的(de)(de)(de)(de)感覺。當然(ran)其效果(guo)也與氫(qing)氣(qi)(qi)的(de)(de)(de)(de)含量與加熱(re)的(de)(de)(de)(de)次(ci)數有關。

During the manufacturing process of the steel pipe,the grease grains used for lubrication will also be deformed due to processing.In order to avoid the grease remaining in the steel pipe,argon gas is used as the furnace atmosphere at high temperature during annealing.Oxygen combined combustion further cleans the surface of the steel pipe to produce a bright surface effect.This kind of annealing and heating with pure argon gas is called bright annealing in the way of brightening the surface.Although using this method to brighten the surface can keep the steel pipe sufficiently clean without any external pollution.However,if the brightness of this surface is mechanical,chemical,or electrolytic compared to other polishing methods,it will feel matte.Of course,the effect is also related to the content of argon gas and the number of heating times.

EP(Electro Polishing)電解光

電解拋光是(shi)利用(yong)陽極處理的(de)(de)方(fang)式,借由電化學的(de)(de)原(yuan)理,適當地(di)調整電壓、電流、酸液組成(cheng)、以及拋光時間(jian),不但(dan)可(ke)(ke)以使(shi)表(biao)面達到明亮、順(shun)滑、潔凈的(de)(de)效果,更可(ke)(ke)以提(ti)升表(biao)面的(de)(de)抗腐蝕性,所以是(shi)最佳的(de)(de)亮化表(biao)面的(de)(de)方(fang)法,當然其成(cheng)本和技(ji)術也(ye)相應的(de)(de)提(ti)高不少。

不過,因為電解拋(pao)光會凸(tu)顯(xian)鋼(gang)管(guan)表(biao)面(mian)的(de)原始狀(zhuang)態,所以若鋼(gang)管(guan)表(biao)面(mian)有(you)嚴重刮傷、孔洞,或是(shi)夾渣、析出(chu)物等,皆可(ke)能(neng)造成電解失敗。其與化(hua)學拋(pao)光不同之處(chu)是(shi),雖(sui)然也是(shi)在酸性環境(jing)中進行,但(dan)鋼(gang)管(guan)表(biao)面(mian)不但(dan)不會有(you)任何晶界(jie)腐(fu)蝕現(xian)象,可(ke)經由(you)控制表(biao)面(mian)的(de)氧化(hua)銘膜(mo)層厚度,使鋼(gang)管(guan)達到的(de)抗蝕性。

However,because the electrolytic polishing will highlight the original state of the surface of the steel pipe,if the surface of the steel pipe has serious scratches,holes,or slag,precipitates,etc.,it may cause electrolytic failure.

The difference between it and chemical polishing is that although it is also carried out in an acidic environment,the surface of the steel pipe will not have any grain boundary corrosion,and the corrosion resistance of the steel pipe can be achieved by controlling the thickness of the chromium oxide film on the surface.

這(zhe)篇文章主要(yao)給大(da)家講解什么是AP級(ji)、MP級(ji)、BA級(ji)、EP級(ji)不銹(xiu)鋼管,AP級(ji)、MP級(ji)、BA級(ji)、EP級(ji)不銹(xiu)鋼管各種(zhong)區別和等級(ji)要(yao)求。希望對大(da)家有所幫助,有關這(zhe)方問(wen)題,可以隨時來電咨詢。