奧氏體(ti)不(bu)銹鋼的縫(feng)焊(han)(han),其焊(han)(han)接(jie)接(jie)頭的力學性(xing)能(neng)(neng)、焊(han)(han)接(jie)質量及焊(han)(han)接(jie)條件(jian)(jian)等(deng),都(dou)與(yu)點(dian)(dian)焊(han)(han)一(yi)樣。選(xuan)擇焊(han)(han)接(jie)條件(jian)(jian)時(shi),因(yin)為(wei)母材的高(gao)強(qiang)度高(gao),應(ying)采用(yong)較高(gao)的電(dian)(dian)(dian)(dian)極壓(ya)力來抑(yi)制產生焊(han)(han)接(jie)缺(que)陷。通(tong)(tong)(tong)電(dian)(dian)(dian)(dian)時(shi)間(jian)宜短(duan),通(tong)(tong)(tong)電(dian)(dian)(dian)(dian)中電(dian)(dian)(dian)(dian)極移動距(ju)離要小。通(tong)(tong)(tong)電(dian)(dian)(dian)(dian)時(shi)間(jian)短(duan),電(dian)(dian)(dian)(dian)流強(qiang)度就要加大(da),電(dian)(dian)(dian)(dian)極的消耗(hao)就加快。若是斷續通(tong)(tong)(tong)電(dian)(dian)(dian)(dian),斷電(dian)(dian)(dian)(dian)時(shi)間(jian)應(ying)是通(tong)(tong)(tong)電(dian)(dian)(dian)(dian)時(shi)間(jian)的兩倍以(yi)上。若斷電(dian)(dian)(dian)(dian)時(shi)間(jian)或者焊(han)(han)接(jie)速(su)度慢(man),可(ke)能(neng)(neng)因(yin)為(wei)分流作(zuo)用(yong),在(zai)焊(han)(han)接(jie)下一(yi)個(ge)點(dian)(dian)時(shi),使前一(yi)個(ge)焊(han)(han)點(dian)(dian)再(zai)熔化,可(ke)能(neng)(neng)因(yin)為(wei)對該(gai)點(dian)(dian)已經不(bu)受壓(ya)力而產生缺(que)陷。

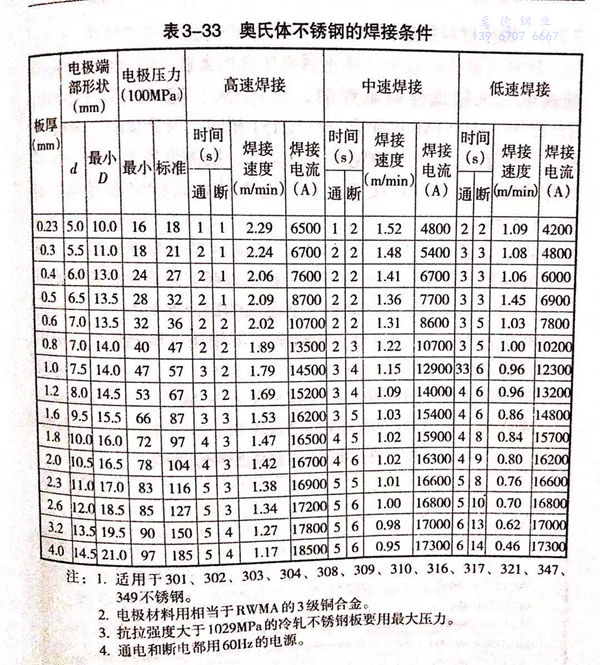

要想得(de)到致密(mi)的(de)縫焊(han)(han)接(jie)頭,除應當(dang)選用(yong)合適的(de)焊(han)(han)接(jie)電(dian)(dian)(dian)流(liu)外(wai),還要調(diao)整焊(han)(han)接(jie)速度及通/斷電(dian)(dian)(dian)時間。要使焊(han)(han)點(dian)的(de)重復量達到焊(han)(han)點(dian)直徑的(de)10%~25%。表3-33所示為奧氏體不(bu)(bu)銹鋼的(de)焊(han)(han)接(jie)條件。由于不(bu)(bu)銹鋼的(de)熱傳導不(bu)(bu)良及電(dian)(dian)(dian)阻率較(jiao)大,所以,連續(xu)通電(dian)(dian)(dian)比斷續(xu)通電(dian)(dian)(dian)對(dui)母材的(de)熱影(ying)響大,變形(xing)也大。電(dian)(dian)(dian)極(ji)材料適用(yong)RWMA的(de)2級或(huo)3級,電(dian)(dian)(dian)極(ji)端部要平或(huo)者梯形(xing)。