固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)是(shi)將合金(jin)(jin)加熱到(dao)高溫(wen)(wen)(wen)(wen)(wen)單-相(xiang)(xiang)區恒溫(wen)(wen)(wen)(wen)(wen)保(bao)(bao)持,使(shi)過(guo)剩相(xiang)(xiang)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)解(jie)(jie)到(dao)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)體后快速冷卻(que)、以(yi)(yi)得到(dao)過(guo)飽(bao)(bao)和(he)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)體的(de)(de)(de)熱處(chu)(chu)理(li)(li)(li)(li)(li)工(gong)(gong)藝(yi)。首先,固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)是(shi)為了溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)解(jie)(jie)基(ji)體內碳化(hua)(hua)物、γ'相(xiang)(xiang)等以(yi)(yi)得到(dao)均勻的(de)(de)(de)過(guo)飽(bao)(bao)和(he)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)體,便(bian)于時效時重新析(xi)(xi)(xi)出(chu)顆粒細小(xiao)、分布(bu)均勻的(de)(de)(de)碳化(hua)(hua)物和(he)γ'等強(qiang)(qiang)化(hua)(hua)相(xiang)(xiang),同時消(xiao)除(chu)由于冷熱加工(gong)(gong)產生(sheng)的(de)(de)(de)應(ying)力。使(shi)合金(jin)(jin)發(fa)生(sheng)再結(jie)晶(jing)。其次,固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)是(shi)為了獲得適宜的(de)(de)(de)晶(jing)粒度(du),以(yi)(yi)保(bao)(bao)證合金(jin)(jin)高溫(wen)(wen)(wen)(wen)(wen)抗蠕(ru)變(bian)性能。固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)的(de)(de)(de)溫(wen)(wen)(wen)(wen)(wen)度(du)范(fan)圍為980~1250℃,主要(yao)(yao)根據各(ge)個合金(jin)(jin)中(zhong)相(xiang)(xiang)析(xi)(xi)(xi)出(chu)和(he)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)解(jie)(jie)規律及使(shi)用(yong)要(yao)(yao)求(qiu)來選(xuan)擇(ze),以(yi)(yi)保(bao)(bao)證主要(yao)(yao)強(qiang)(qiang)化(hua)(hua)相(xiang)(xiang)必要(yao)(yao)的(de)(de)(de)析(xi)(xi)(xi)出(chu)條件和(he)一定的(de)(de)(de)晶(jing)粒度(du)。對(dui)于長期(qi)高溫(wen)(wen)(wen)(wen)(wen)使(shi)用(yong)的(de)(de)(de)合金(jin)(jin),要(yao)(yao)求(qiu)有較(jiao)好的(de)(de)(de)高溫(wen)(wen)(wen)(wen)(wen)持久和(he)蠕(ru)變(bian)性能,應(ying)選(xuan)擇(ze)較(jiao)高的(de)(de)(de)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)溫(wen)(wen)(wen)(wen)(wen)度(du)以(yi)(yi)獲得較(jiao)大(da)的(de)(de)(de)晶(jing)粒度(du);對(dui)于中(zhong)溫(wen)(wen)(wen)(wen)(wen)使(shi)用(yong)并要(yao)(yao)求(qiu)較(jiao)好的(de)(de)(de)室溫(wen)(wen)(wen)(wen)(wen)硬度(du)、屈服(fu)強(qiang)(qiang)度(du)、拉伸強(qiang)(qiang)度(du)、沖擊韌(ren)性和(he)疲勞強(qiang)(qiang)度(du)的(de)(de)(de)合金(jin)(jin),可(ke)采用(yong)較(jiao)低的(de)(de)(de)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)溫(wen)(wen)(wen)(wen)(wen)度(du),保(bao)(bao)證較(jiao)小(xiao)的(de)(de)(de)晶(jing)粒度(du)。高溫(wen)(wen)(wen)(wen)(wen)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)時,各(ge)種(zhong)析(xi)(xi)(xi)出(chu)相(xiang)(xiang)都逐步(bu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)解(jie)(jie),同時晶(jing)粒長大(da);低溫(wen)(wen)(wen)(wen)(wen)固(gu)(gu)(gu)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)處(chu)(chu)理(li)(li)(li)(li)(li)時,不僅有主要(yao)(yao)強(qiang)(qiang)化(hua)(hua)相(xiang)(xiang)的(de)(de)(de)溶(rong)(rong)(rong)(rong)(rong)(rong)(rong)解(jie)(jie),而且可(ke)能有某些相(xiang)(xiang)的(de)(de)(de)析(xi)(xi)(xi)出(chu)。對(dui)于過(guo)飽(bao)(bao)和(he)度(du)低的(de)(de)(de)合金(jin)(jin),通常選(xuan)擇(ze)較(jiao)快的(de)(de)(de)冷卻(que)速度(du);對(dui)于過(guo)飽(bao)(bao)和(he)度(du)高的(de)(de)(de)合金(jin)(jin),通常為空氣(qi)中(zhong)冷卻(que)。

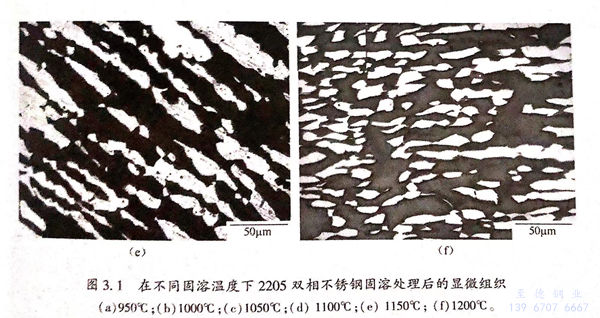

對2205雙相不銹鋼進行不同溫度的固溶處理會導致2205雙相不銹(xiu)鋼兩相組織的改變,進而導致其性能的差異,圖3.1是在不同溫度下2205雙相不銹鋼固溶處理后的微觀組織。

選(xuan)取1000℃作(zuo)為(wei)(wei)最低(di)固溶(rong)溫(wen)度(du),當(dang)熱(re)處理溫(wen)度(du)低(di)于950℃時(shi),雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹(xiu)(xiu)鋼基體(ti)會析出雜質相(xiang)(xiang)(xiang)(xiang)(xiang)σ相(xiang)(xiang)(xiang)(xiang)(xiang),σ相(xiang)(xiang)(xiang)(xiang)(xiang)作(zuo)為(wei)(wei)富含Cr、Mo的硬脆相(xiang)(xiang)(xiang)(xiang)(xiang),其存在(zai)降(jiang)低(di)雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹(xiu)(xiu)鋼的耐蝕性能。圖3.1(a)為(wei)(wei)950℃的微觀組織,。相(xiang)(xiang)(xiang)(xiang)(xiang)廣泛分(fen)布于鐵素(su)體(ti)/奧(ao)氏體(ti)晶界。當(dang)溫(wen)度(du)達到1000℃時(shi),σ相(xiang)(xiang)(xiang)(xiang)(xiang)會消(xiao)失,雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹(xiu)(xiu)鋼中(zhong)只存在(zai)鐵素(su)體(ti)相(xiang)(xiang)(xiang)(xiang)(xiang)和奧(ao)氏體(ti)相(xiang)(xiang)(xiang)(xiang)(xiang)。圖3.1(b)~(f)中(zhong)深色區為(wei)(wei)鐵素(su)體(ti),淺色區為(wei)(wei)奧(ao)氏體(ti)。奧(ao)氏體(ti)以鐵素(su)體(ti)為(wei)(wei)基體(ti),呈帶(dai)狀或(huo)島狀分(fen)布于鐵素(su)體(ti)上。隨(sui)著溫(wen)度(du)的升(sheng)高,奧(ao)氏體(ti)晶粒尺寸(cun)變大。

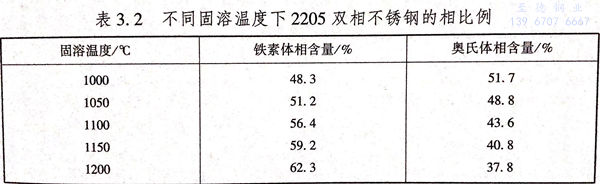

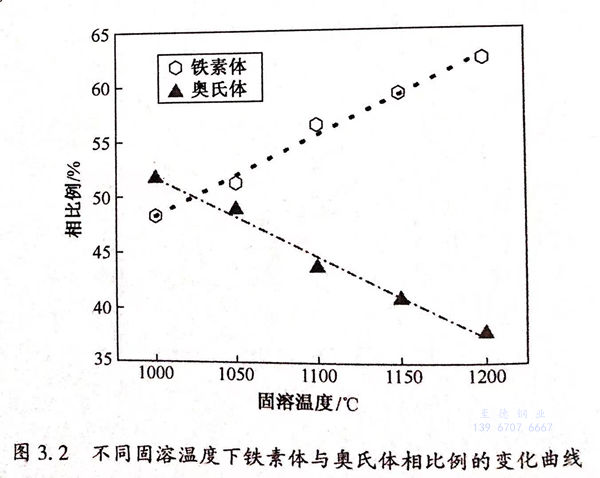

利(li)用IAS圖(tu)像(xiang)(xiang)分(fen)析軟(ruan)件測(ce)量(liang)(liang)并計(ji)算相(xiang)(xiang)比例,每(mei)個(ge)熱處理溫(wen)(wen)(wen)度(du)下的(de)(de)(de)金相(xiang)(xiang)圖(tu)取8張計(ji)算,求取平均值(zhi)。表3.2給出了利(li)用IAS圖(tu)像(xiang)(xiang)分(fen)析軟(ruan)件計(ji)算得(de)到不同固(gu)溶溫(wen)(wen)(wen)度(du)溫(wen)(wen)(wen)度(du)下2205雙(shuang)相(xiang)(xiang)不銹(xiu)鋼(gang)的(de)(de)(de)相(xiang)(xiang)比例。1000℃時(shi)(shi),鐵(tie)素(su)(su)(su)體(ti)含(han)(han)(han)量(liang)(liang)為(wei)48.3%,隨著固(gu)溶溫(wen)(wen)(wen)度(du)的(de)(de)(de)升高,鐵(tie)素(su)(su)(su)體(ti)相(xiang)(xiang)含(han)(han)(han)量(liang)(liang)增加,奧(ao)(ao)氏體(ti)相(xiang)(xiang)含(han)(han)(han)量(liang)(liang)下降(jiang),直到1200℃時(shi)(shi),鐵(tie)素(su)(su)(su)體(ti)含(han)(han)(han)量(liang)(liang)達到62.3%,奧(ao)(ao)氏體(ti)含(han)(han)(han)量(liang)(liang)僅占(zhan)37.7%.這(zhe)種(zhong)鐵(tie)素(su)(su)(su)體(ti)與奧(ao)(ao)氏體(ti)隨固(gu)溶溫(wen)(wen)(wen)度(du)的(de)(de)(de)變化(hua)(hua)規律前(qian)人(ren)的(de)(de)(de)研究結果相(xiang)(xiang)一致。兩(liang)相(xiang)(xiang)比例的(de)(de)(de)變化(hua)(hua)曲線(xian)如圖(tu)3.2所(suo)示,兩(liang)相(xiang)(xiang)與溫(wen)(wen)(wen)度(du)的(de)(de)(de)關系呈線(xian)性變化(hua)(hua)。當固(gu)溶溫(wen)(wen)(wen)度(du)約為(wei)1040℃時(shi)(shi),其相(xiang)(xiang)比例為(wei)1:1。

因此在本(ben)實驗(yan)的(de)6個固溶(rong)溫(wen)度中,當固溶(rong)溫(wen)度為1050℃時,雙(shuang)相不銹鋼相比例最接近1:1。

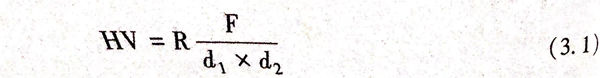

采用顯微硬(ying)度(du)儀壓頭為菱形壓頭,荷載F為4.8N,分別測出菱形的兩(liang)個直徑d1和(he)d2,根據(ju)下式計算顯微硬(ying)度(du):

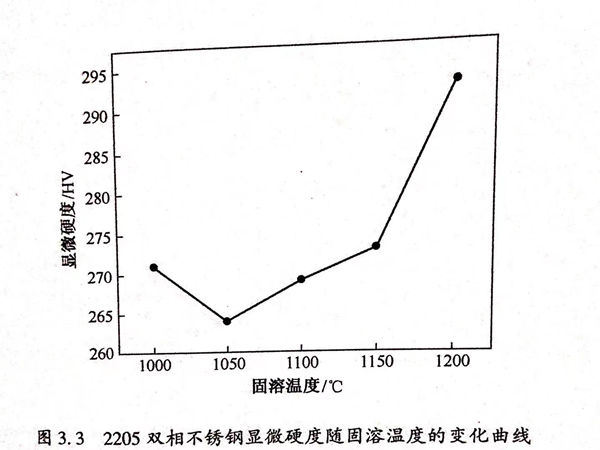

所(suo)有固(gu)溶(rong)溫(wen)度試(shi)樣均測5個點,最(zui)后求取平均值為個固(gu)溶(rong)溫(wen)度下2205雙相(xiang)不銹鋼的(de)顯微(wei)硬(ying)度值。顯微(wei)硬(ying)度值如表3.3所(suo)列,顯微(wei)硬(ying)度隨(sui)固(gu)溶(rong)溫(wen)度的(de)變化曲線如圖(tu)3.3所(suo)示(shi)。

從圖3.3可知,2205雙相不銹鋼的顯微硬度先下降,后上升。這主要是由于當溫度為1000℃時,鐵素體相中間夾雜著小塊狀的二次奧氏體,當溫度達到1050℃后,二次奧氏體含量減少,組織均勻化程度提高,硬度減小。在此之后,隨著固溶溫度的增加,奧氏體含量減少,具有體心立方結構的奧氏體相屬于軟軔相,具有面心立方結構的鐵素體是強硬相,因此材料顯微硬度值又升高。同樣對2507雙相不銹(xiu)鋼進行不同溫度的固溶處理會導致2507雙相不銹鋼兩相組織的改變,進而導致其性能的差異,以下是2507雙相不銹鋼在不同溫度下固溶處理后的微觀組織。

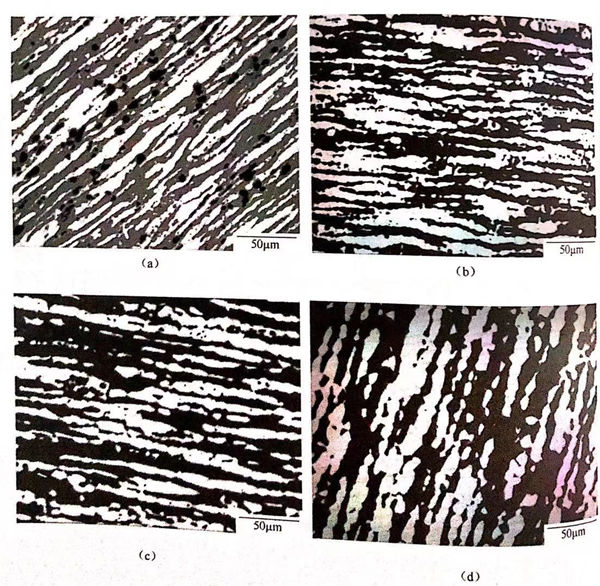

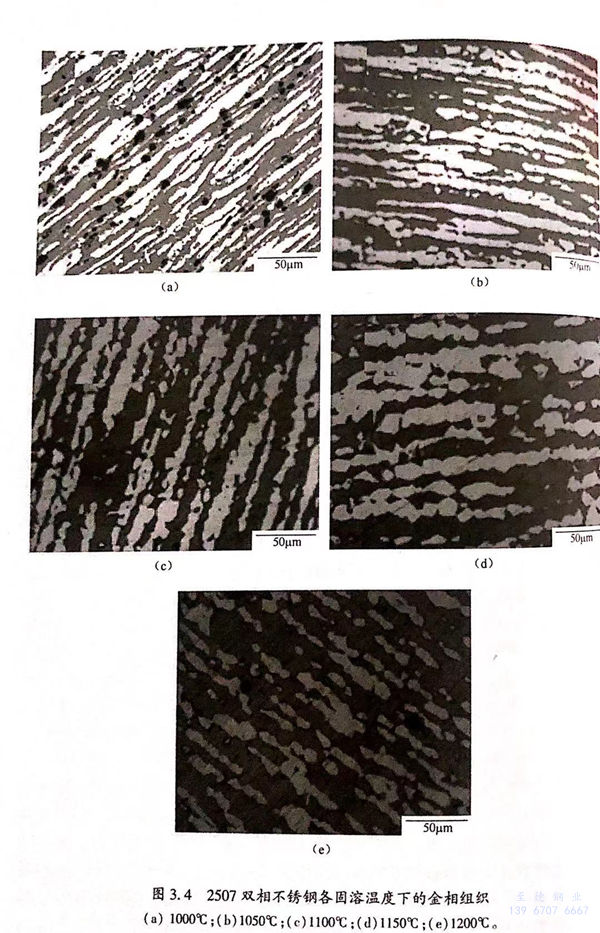

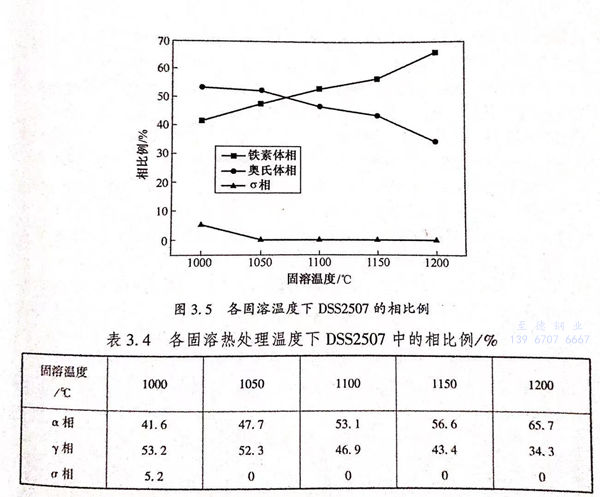

2507雙(shuang)(shuang)相(xiang)(xiang)(xiang)不(bu)銹(xiu)鋼分別在1000℃、1050℃、1100℃、1150℃、1200℃下固(gu)溶(rong)(rong)0.5h后水冷(leng)的(de)(de)金相(xiang)(xiang)(xiang)組織如圖(tu)3.4所(suo)示(shi)(shi)。從圖(tu)3.4可以清(qing)晰地得知(zhi)當(dang)固(gu)溶(rong)(rong)溫(wen)(wen)度(du)為1000℃時(shi)鐵素體相(xiang)(xiang)(xiang)與奧氏體相(xiang)(xiang)(xiang)兩相(xiang)(xiang)(xiang)相(xiang)(xiang)(xiang)界處(chu)(chu)有σ相(xiang)(xiang)(xiang)析(xi)出,隨固(gu)溶(rong)(rong)處(chu)(chu)理溫(wen)(wen)度(du)升高到1050℃時(shi)σ相(xiang)(xiang)(xiang)已經溶(rong)(rong)解(jie)。利(li)用(yong)(yong)Image-Pro-Plus 圖(tu)像分析(xi)儀軟件6.0版測定(ding)的(de)(de)相(xiang)(xiang)(xiang)比例(li)如圖(tu)3.5所(suo)示(shi)(shi)。從圖(tu)3.5能夠(gou)獲得固(gu)溶(rong)(rong)熱(re)處(chu)(chu)理溫(wen)(wen)度(du)的(de)(de)增高會導致(zhi)σ析(xi)出相(xiang)(xiang)(xiang)含量(liang)(liang)降(jiang)(jiang)低(di),當(dang)固(gu)溶(rong)(rong)熱(re)處(chu)(chu)理溫(wen)(wen)度(du)大于(yu)1050℃時(shi)σ相(xiang)(xiang)(xiang)已經完全溶(rong)(rong)解(jie)。這是由于(yu)固(gu)溶(rong)(rong)熱(re)處(chu)(chu)理溫(wen)(wen)度(du)的(de)(de)升高使鋼中(zhong)鐵素體α相(xiang)(xiang)(xiang)量(liang)(liang)增多,導致(zhi)σ相(xiang)(xiang)(xiang)形成元素Cr和(he)Mo在鐵素體相(xiang)(xiang)(xiang)中(zhong)的(de)(de)濃度(du)降(jiang)(jiang)低(di),進而(er)導致(zhi)當(dang)固(gu)溶(rong)(rong)熱(re)處(chu)(chu)理溫(wen)(wen)度(du)大于(yu)1050℃時(shi)σ相(xiang)(xiang)(xiang)的(de)(de)形成受(shou)到抑(yi)制。考(kao)慮到σ相(xiang)(xiang)(xiang)硬且脆(cui),能夠(gou)大幅度(du)減弱材料(liao)的(de)(de)塑性(xing)與韌性(xing),并(bing)且σ相(xiang)(xiang)(xiang)富Cr,很(hen)容易在其周圍產生貧Cr區降(jiang)(jiang)低(di)DSS2507的(de)(de)抗腐蝕(shi)性(xing)能,所(suo)以σ相(xiang)(xiang)(xiang)為DSS2507析(xi)出相(xiang)(xiang)(xiang)中(zhong)危害(hai)最大的(de)(de)相(xiang)(xiang)(xiang),因此,在實際(ji)應用(yong)(yong)過程(cheng)中(zhong)要(yao)想將2507雙(shuang)(shuang)相(xiang)(xiang)(xiang)不(bu)銹(xiu)鋼中(zhong)的(de)(de)熱(re)軋態σ相(xiang)(xiang)(xiang)完全消除所(suo)選用(yong)(yong)的(de)(de)固(gu)溶(rong)(rong)溫(wen)(wen)度(du)要(yao)不(bu)低(di)于(yu)1050℃。

圖(tu)3.4中深色組織是鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)α相(xiang)(xiang)(xiang)(xiang)、淺(qian)色組織是奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)。從圖(tu)3.4可知奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)首先表現為長條狀,隨(sui)(sui)著固(gu)(gu)溶(rong)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)升高(gao)而(er)逐(zhu)(zhu)漸變短,變成(cheng)島狀分布在基體(ti)(ti)(ti)(ti)(ti)(ti)(ti)鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)上面(mian)。從圖(tu)3.5及表3.4中給出(chu)的(de)(de)相(xiang)(xiang)(xiang)(xiang)比(bi)例測量結(jie)果能夠獲得鋼中鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)α相(xiang)(xiang)(xiang)(xiang)量隨(sui)(sui)固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)升高(gao)而(er)上升,奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)積分數隨(sui)(sui)著固(gu)(gu)溶(rong)溫(wen)度(du)(du)的(de)(de)上升而(er)下(xia)降(jiang),這(zhe)(zhe)是由于(yu)在較(jiao)(jiao)(jiao)高(gao)的(de)(de)固(gu)(gu)溶(rong)溫(wen)度(du)(du)下(xia)2507雙相(xiang)(xiang)(xiang)(xiang)不銹(xiu)鋼呈現出(chu)的(de)(de)組織為單一的(de)(de)鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti),隨(sui)(sui)固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)降(jiang)低鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)逐(zhu)(zhu)步轉化為奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)組織,即固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)升高(gao)導(dao)致(zhi)奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)逐(zhu)(zhu)漸轉變為鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)組織。從圖(tu)3.5可以看出(chu)當(dang)固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)在1000~1050℃之(zhi)間時奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)y相(xiang)(xiang)(xiang)(xiang)比(bi)例減(jian)小的(de)(de)比(bi)較(jiao)(jiao)(jiao)緩慢,隨(sui)(sui)固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)升高(gao)奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)含量減(jian)少的(de)(de)趨勢加快,這(zhe)(zhe)是因為2507雙相(xiang)(xiang)(xiang)(xiang)不銹(xiu)鋼中的(de)(de)氮(dan)元素(su)(su)是奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)形成(cheng)元素(su)(su),在較(jiao)(jiao)(jiao)低固(gu)(gu)溶(rong)溫(wen)度(du)(du)下(xia)抑制了奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)相(xiang)(xiang)(xiang)(xiang)向(xiang)鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)相(xiang)(xiang)(xiang)(xiang)的(de)(de)轉變,而(er)固(gu)(gu)溶(rong)熱(re)(re)處(chu)(chu)(chu)理(li)(li)(li)(li)溫(wen)度(du)(du)的(de)(de)升高(gao)會使N元素(su)(su)穩定奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)相(xiang)(xiang)(xiang)(xiang)的(de)(de)作用逐(zhu)(zhu)漸減(jian)弱,進(jin)而(er)導(dao)致(zhi)奧(ao)(ao)氏(shi)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)向(xiang)鐵素(su)(su)體(ti)(ti)(ti)(ti)(ti)(ti)(ti)α相(xiang)(xiang)(xiang)(xiang)轉變速度(du)(du)加快。

2507雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹鋼中的(de)(de)(de)(de)奧(ao)(ao)氏(shi)體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)(xiang)和(he)鐵素體(ti)(ti)相(xiang)(xiang)(xiang)(xiang)(xiang)這(zhe)兩(liang)(liang)種相(xiang)(xiang)(xiang)(xiang)(xiang)的(de)(de)(de)(de)相(xiang)(xiang)(xiang)(xiang)(xiang)比(bi)例(li)(li)主(zhu)要受固(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)工藝(yi)以及自身化(hua)學成(cheng)分(fen)的(de)(de)(de)(de)影響(xiang),當(dang)鋼的(de)(de)(de)(de)主(zhu)要化(hua)學成(cheng)分(fen)確定時,則兩(liang)(liang)相(xiang)(xiang)(xiang)(xiang)(xiang)比(bi)例(li)(li)與固(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)制(zhi)度(du)(du)有著(zhu)(zhu)密切聯系。DSS2507的(de)(de)(de)(de)相(xiang)(xiang)(xiang)(xiang)(xiang)比(bi)例(li)(li)又影響(xiang)著(zhu)(zhu)其自身的(de)(de)(de)(de)性能(neng)(neng),其塑性隨著(zhu)(zhu)鐵素體(ti)(ti)含(han)(han)量的(de)(de)(de)(de)增多(duo)而減弱、耐應力(li)(li)腐(fu)蝕破裂能(neng)(neng)力(li)(li)隨著(zhu)(zhu)奧(ao)(ao)氏(shi)體(ti)(ti)含(han)(han)量升高而減弱,進(jin)而認為(wei)當(dang)鐵素體(ti)(ti)α相(xiang)(xiang)(xiang)(xiang)(xiang)跟奧(ao)(ao)氏(shi)體(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)(xiang)這(zhe)兩(liang)(liang)相(xiang)(xiang)(xiang)(xiang)(xiang)相(xiang)(xiang)(xiang)(xiang)(xiang)比(bi)例(li)(li)接近1:1時雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹鋼的(de)(de)(de)(de)綜合性能(neng)(neng)最(zui)佳,有較(jiao)好的(de)(de)(de)(de)抗腐(fu)蝕能(neng)(neng)力(li)(li)以及較(jiao)優的(de)(de)(de)(de)力(li)(li)學性能(neng)(neng)。從圖3.5可(ke)知(zhi)固(gu)(gu)溶(rong)(rong)(rong)(rong)熱處(chu)(chu)理(li)溫(wen)度(du)(du)在1050~1100℃之間時可(ke)以使(shi)鋼中的(de)(de)(de)(de)兩(liang)(liang)相(xiang)(xiang)(xiang)(xiang)(xiang)組織(zhi)比(bi)例(li)(li)達到1:1,本(ben)實(shi)驗中所選用(yong)(yong)的(de)(de)(de)(de)5種固(gu)(gu)溶(rong)(rong)(rong)(rong)溫(wen)度(du)(du)中1050℃時鐵素體(ti)(ti)α相(xiang)(xiang)(xiang)(xiang)(xiang)跟奧(ao)(ao)氏(shi)體(ti)(ti)γ相(xiang)(xiang)(xiang)(xiang)(xiang)比(bi)例(li)(li)最(zui)接近1:1,進(jin)而可(ke)以認為(wei)選擇較(jiao)優的(de)(de)(de)(de)固(gu)(gu)溶(rong)(rong)(rong)(rong)熱處(chu)(chu)理(li)溫(wen)度(du)(du)使(shi)DSS2507中的(de)(de)(de)(de)兩(liang)(liang)相(xiang)(xiang)(xiang)(xiang)(xiang)含(han)(han)量比(bi)例(li)(li)達到1:1是有可(ke)能(neng)(neng)的(de)(de)(de)(de),在實(shi)際(ji)應用(yong)(yong)過程(cheng)中為(wei)了使(shi)2507雙相(xiang)(xiang)(xiang)(xiang)(xiang)不(bu)銹鋼獲得較(jiao)好的(de)(de)(de)(de)綜合性能(neng)(neng),進(jin)行固(gu)(gu)溶(rong)(rong)(rong)(rong)處(chu)(chu)理(li)時選取(qu)的(de)(de)(de)(de)固(gu)(gu)溶(rong)(rong)(rong)(rong)溫(wen)度(du)(du)應該在1050~1100℃之間。

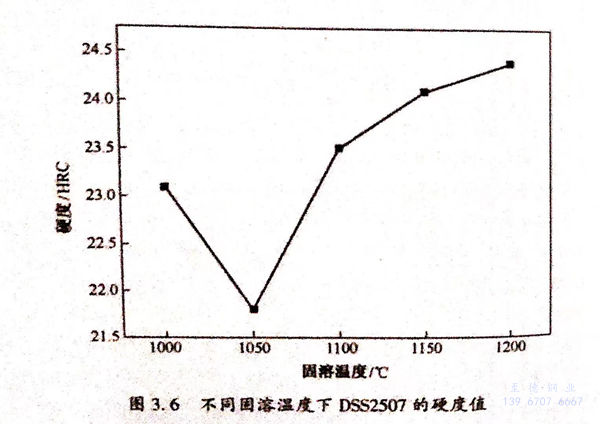

2507雙相(xiang)(xiang)(xiang)不銹鋼(gang)分別在(zai)(zai)1000℃、1050℃、1100℃、1150℃、1200℃固(gu)(gu)溶(rong)0.5h后(hou)水(shui)冷的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)值如圖3.6所(suo)(suo)(suo)示。從圖3.6可知DSS2507的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)隨(sui)固(gu)(gu)溶(rong)處(chu)(chu)理(li)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)升(sheng)(sheng)(sheng)(sheng)高(gao)先減(jian)小后(hou)變大呈曲線變化。在(zai)(zai)1000~1050℃溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)范(fan)圍(wei)內鋼(gang)的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)隨(sui)固(gu)(gu)溶(rong)熱處(chu)(chu)理(li)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)增高(gao)而(er)(er)逐(zhu)(zhu)漸減(jian)小,1050~1200℃范(fan)圍(wei)內隨(sui)固(gu)(gu)溶(rong)熱處(chu)(chu)理(li)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)上升(sheng)(sheng)(sheng)(sheng)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)又漸漸變大,且1050℃時(shi)(shi)DSS2507的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)表現為(wei)最小。從3.2.1節(jie)分析(xi)可知當(dang)固(gu)(gu)溶(rong)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)為(wei)1000℃時(shi)(shi)在(zai)(zai)鐵(tie)(tie)素體(ti)和奧氏體(ti)相(xiang)(xiang)(xiang)界處(chu)(chu)有σ相(xiang)(xiang)(xiang)析(xi)出(chu),σ相(xiang)(xiang)(xiang)是一(yi)種硬(ying)(ying)(ying)而(er)(er)脆的(de)(de)(de)(de)相(xiang)(xiang)(xiang),能夠提高(gao)雙相(xiang)(xiang)(xiang)不銹鋼(gang)的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)值,所(suo)(suo)(suo)以1000℃下鋼(gang)有較高(gao)的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du),而(er)(er)σ相(xiang)(xiang)(xiang)會隨(sui)固(gu)(gu)溶(rong)熱處(chu)(chu)理(li)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)升(sheng)(sheng)(sheng)(sheng)高(gao)而(er)(er)漸漸溶(rong)解到基(ji)體(ti)中,DSS2507的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)有下降(jiang)的(de)(de)(de)(de)趨(qu)勢(shi);同時(shi)(shi)又由于(yu)固(gu)(gu)溶(rong)熱處(chu)(chu)理(li)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)增高(gao)導致鋼(gang)中的(de)(de)(de)(de)鐵(tie)(tie)素體(ti)相(xiang)(xiang)(xiang)量(liang)(liang)增加而(er)(er)奧氏體(ti)相(xiang)(xiang)(xiang)量(liang)(liang)降(jiang)低,在(zai)(zai)室溫(wen)(wen)(wen)下鐵(tie)(tie)素體(ti)是體(ti)心(xin)(xin)立方結構(bcc)奧氏體(ti)是面心(xin)(xin)立方結構(fcc),前者硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)要高(gao)于(yu)后(hou)者,因此在(zai)(zai)鐵(tie)(tie)素體(ti)含量(liang)(liang)逐(zhu)(zhu)漸升(sheng)(sheng)(sheng)(sheng)高(gao)的(de)(de)(de)(de)情況下鋼(gang)的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)也逐(zhu)(zhu)漸升(sheng)(sheng)(sheng)(sheng)高(gao),即(ji)隨(sui)著(zhu)固(gu)(gu)溶(rong)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)的(de)(de)(de)(de)升(sheng)(sheng)(sheng)(sheng)高(gao)2507 雙相(xiang)(xiang)(xiang)不銹鋼(gang)的(de)(de)(de)(de)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)呈升(sheng)(sheng)(sheng)(sheng)高(gao)的(de)(de)(de)(de)趨(qu)勢(shi)。綜上所(suo)(suo)(suo)述,隨(sui)固(gu)(gu)溶(rong)溫(wen)(wen)(wen)度(du)(du)(du)(du)(du)(du)從1000℃上升(sheng)(sheng)(sheng)(sheng)到1200℃,2507雙相(xiang)(xiang)(xiang)不銹鋼(gang)硬(ying)(ying)(ying)度(du)(du)(du)(du)(du)(du)呈先降(jiang)低后(hou)升(sheng)(sheng)(sheng)(sheng)高(gao)的(de)(de)(de)(de)變化趨(qu)勢(shi)。