對不銹鋼管道(dao)支(zhi)、吊(diao)架制作,其(qi)選(xuan)型、材質(zhi)、加工(gong)(gong)(gong)尺寸(cun)應符合設計(ji)要求,要檢查其(qi)加工(gong)(gong)(gong)合格(ge)證(zheng)或按施工(gong)(gong)(gong)圖核對。焊接質(zhi)量要牢固,無漏焊、裂紋等缺(que)陷。支(zhi)、吊(diao)架外形規整(zheng),焊縫表面光潔(jie),整(zheng)體美觀大方。對于(yu)工(gong)(gong)(gong)廠加工(gong)(gong)(gong)的產(chan)品,每一品種應抽查10%,且不得(de)小(xiao)于(yu)3件。

不(bu)銹鋼管道支、吊架安裝與固定一般有埋栽、夾于柱上、預埋件焊接、用膨脹螺栓或射釘固定等多種方法。在各種支、吊架結構圖、表中已對固定方法作了說明,施工要點分析如下。

1. 埋栽法(fa)

其施(shi)工步(bu)驟(zou)為放(fang)線(xian)(xian)(xian)、支架(jia)位(wei)置定(ding)(ding)位(wei)、打(da)(da)(da)洞(dong)(dong)(dong)、插埋(mai)支梁。放(fang)線(xian)(xian)(xian)也稱放(fang)坡(po)(po),按管(guan)道的(de)(de)設計安裝標高(gao)(gao)及坡(po)(po)度(du)(du)要(yao)求,在墻(qiang)壁上用(yong)(yong)墨線(xian)(xian)(xian)彈畫出管(guan)道安裝坡(po)(po)度(du)(du)線(xian)(xian)(xian),或以(yi)兩端為基準點、確定(ding)(ding)標高(gao)(gao)后(hou),按支架(jia)距離算出每(mei)(mei)點標高(gao)(gao),在每(mei)(mei)個(ge)點畫出十字線(xian)(xian)(xian)及打(da)(da)(da)洞(dong)(dong)(dong)方塊線(xian)(xian)(xian)。打(da)(da)(da)洞(dong)(dong)(dong)時用(yong)(yong)錘擊扁鑿,沿(yan)硅縫先(xian)取下整(zheng)磚(zhuan),切斷磚(zhuan)時要(yao)用(yong)(yong)力適當,以(yi)免影響洞(dong)(dong)(dong)線(xian)(xian)(xian)以(yi)外的(de)(de)結構,洞(dong)(dong)(dong)口尺寸及深度(du)(du)依支架(jia)要(yao)求定(ding)(ding)。打(da)(da)(da)洞(dong)(dong)(dong)完畢清(qing)除洞(dong)(dong)(dong)內垃圾(ji),然后(hou)澆(jiao)水,使(shi)洞(dong)(dong)(dong)內四周濕透。插埋(mai)支梁時,先(xian)在支梁上畫出應插入(ru)的(de)(de)深度(du)(du),以(yi)保證每(mei)(mei)個(ge)支梁插入(ru)深度(du)(du)相(xiang)同、滑動支座的(de)(de)中(zhong)心在一條直線(xian)(xian)(xian)上。插入(ru)前可用(yong)(yong)細石(shi)混凝土先(xian)填入(ru)一部分,最后(hou)用(yong)(yong)碎石(shi)擠(ji)牢固并抹(mo)平(ping)洞(dong)(dong)(dong)口。埋(mai)栽的(de)(de)支梁應平(ping)正不(bu)扭曲。

2. 夾柱法(fa)

不銹(xiu)鋼管道沿柱安(an)裝時,可采用支梁(liang)和夾梁(liang)用螺栓夾緊(jin)(jin)在柱子上(shang),將支梁(liang)固定。安(an)裝時,也要(yao)通過拉線(xian)或(huo)計(ji)算出每個(ge)柱上(shang)的(de)支梁(liang)標(biao)高,支梁(liang)緊(jin)(jin)固前靠柱面(mian)部分應作防腐處理,如(ru)刷紅(hong)丹漆。安(an)裝后的(de)支梁(liang)應平正不扭曲。

3. 預埋件焊接法

預埋(mai)件是配合(he)(he)土(tu)建(jian)施工(gong)時埋(mai)入的,預埋(mai)鋼(gang)(gang)板背面應焊上帶鉤(gou)的圓鋼(gang)(gang),以(yi)保(bao)證(zheng)土(tu)建(jian)澆人混凝土(tu)后牢固(gu),帶鉤(gou)的圓鋼(gang)(gang)可(ke)與混凝土(tu)中的鋼(gang)(gang)筋相焊接。預埋(mai)件外表面要平正,標高偏差不大(da),這樣才能保(bao)證(zheng)支梁與其焊接后符合(he)(he)要求(qiu)。

在土建施工中也可采用(yong)埋(mai)設木磚留洞的方(fang)法,作為預埋(mai)件或埋(mai)栽支梁(liang)時第二次澆灌混凝土用(yong)。

4. 膨脹螺栓(shuan)或射釘固定法

這種方法(fa)適用(yong)于在(zai)沒有(you)預(yu)留孔(kong)洞的磚石結(jie)構(gou)及沒有(you)預(yu)埋鋼板的混凝(ning)(ning)土、鋼筋混凝(ning)(ning)土結(jie)構(gou)上安裝支架。在(zai)確定支梁安裝位(wei)置后(hou),并用(yong)支梁實物在(zai)安裝處(chu)確定鉆孔(kong)位(wei)置,鉆孔(kong),打入(ru)膨(peng)脹(zhang)螺栓(shuan)(shuan),將支梁用(yong)膨(peng)脹(zhang)螺栓(shuan)(shuan)的螺母(mu)固緊。

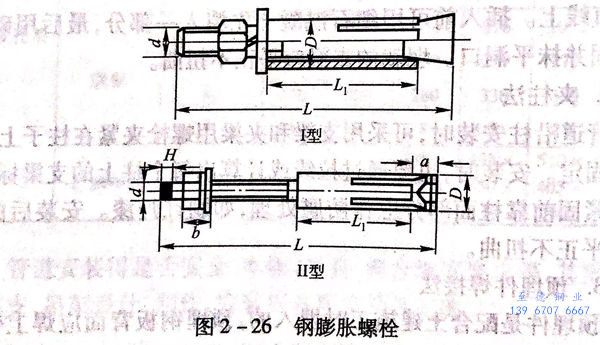

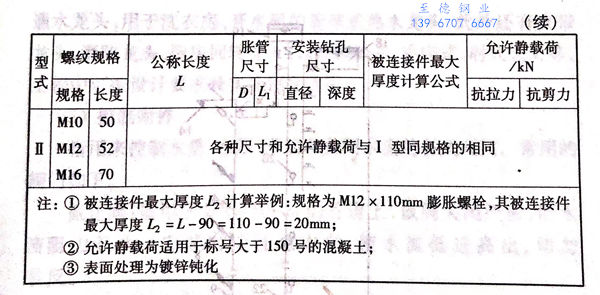

膨脹(zhang)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)全稱為鋼膨脹(zhang)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan),它是一種(zhong)特殊(shu)螺(luo)(luo)(luo)(luo)(luo)紋(wen)連接件(jian)。型(普通型)由(you)沉(chen)頭螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)、脹(zhang)管、平(ping)墊(dian)圈(quan)、彈簧墊(dian)圈(quan)和(he)六角螺(luo)(luo)(luo)(luo)(luo)母(mu)(mu)(mu)組成(cheng)(cheng)(cheng),如圖2-26所示。使(shi)用時(shi)(shi)先用沖擊(ji)鉆在(zai)(zai)安裝(zhuang)位置鉆一個相應(ying)尺寸的(de)孔,鉆成(cheng)(cheng)(cheng)的(de)孔必須與(yu)構件(jian)表面(mian)垂直,并將孔內碎屑清(qing)除干凈。再把(ba)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)、脹(zhang)管裝(zhuang)人孔中,然后依(yi)次(ci)把(ba)構件(jian)(或(huo)(huo)設(she)備)平(ping)墊(dian)圈(quan)、彈簧墊(dian)圈(quan)套在(zai)(zai)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)上面(mian),最后旋緊螺(luo)(luo)(luo)(luo)(luo)母(mu)(mu)(mu),在(zai)(zai)旋緊螺(luo)(luo)(luo)(luo)(luo)母(mu)(mu)(mu)的(de)同時(shi)(shi)把(ba)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)逐(zhu)漸拔起(qi),螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)底部(bu)呈錐(zhui)形(xing)(xing),將脹(zhang)管逐(zhu)步脹(zhang)開與(yu)周圍(wei)磚體或(huo)(huo)混(hun)凝土固緊,使(shi)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)、脹(zhang)管、螺(luo)(luo)(luo)(luo)(luo)母(mu)(mu)(mu)、構件(jian)(或(huo)(huo)設(she)備)與(yu)墻體連接成(cheng)(cheng)(cheng)一個整體。I型不同之(zhi)處是將沉(chen)頭螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)分成(cheng)(cheng)(cheng)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)和(he)錐(zhui)形(xing)(xing)螺(luo)(luo)(luo)(luo)(luo)母(mu)(mu)(mu)兩個零件(jian),可以安裝(zhuang)大型機器、設(she)備,使(shi)用方法與(yu)I型相同。鋼膨脹(zhang)螺(luo)(luo)(luo)(luo)(luo)栓(shuan)(shuan)(shuan)(shuan)規格見表2-12。

用(yong)射(she)釘(ding)安裝(zhuang)支(zhi)梁(liang)的方法與(yu)用(yong)膨(peng)脹(zhang)螺(luo)栓法步驟相同,只是用(yong)射(she)釘(ding)槍(qiang)(qiang)(qiang)打人帶螺(luo)紋的射(she)釘(ding),最(zui)后用(yong)螺(luo)母將支(zhi)梁(liang)緊固。射(she)釘(ding)規格(ge)為8mm~12mm,操作時就將射(she)釘(ding)槍(qiang)(qiang)(qiang)頂住墻壁,用(yong)力壓死槍(qiang)(qiang)(qiang)頭后扣動扳機(ji)使射(she)釘(ding)射(she)入墻內。