一(yi)、鎢(wu)極脈(mo)沖氬弧焊工作(zuo)原理(li)

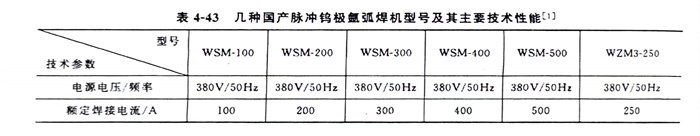

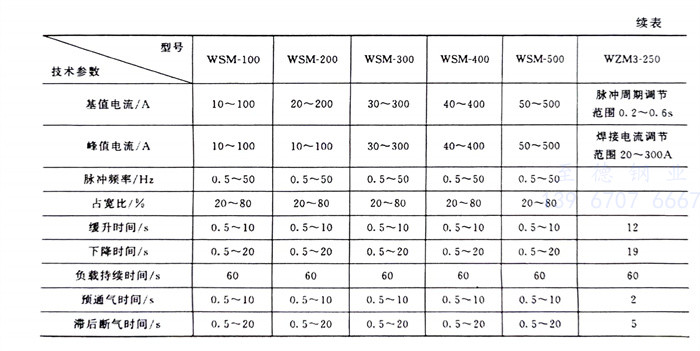

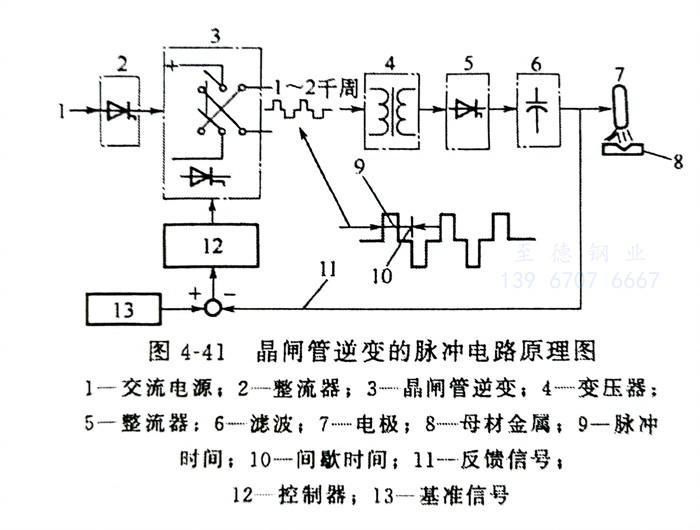

鎢極脈(mo)沖(chong)氬弧(hu)焊(han)(han)(han)(han)是在普通(tong)鎢極氬弧(hu)焊(han)(han)(han)(han)基礎上發展(zhan)起來(lai)的一(yi)(yi)(yi)(yi)種(zhong)新的焊(han)(han)(han)(han)接工藝,通(tong)過控制焊(han)(han)(han)(han)接電(dian)(dian)(dian)流按(an)一(yi)(yi)(yi)(yi)定(ding)頻率(lv)周期地(di)變化。每一(yi)(yi)(yi)(yi)次脈(mo)沖(chong)電(dian)(dian)(dian)流通(tong)過時(shi)(shi),焊(han)(han)(han)(han)件(jian)被加熱(re)熔化,形成一(yi)(yi)(yi)(yi)個(ge)(ge)點狀(zhuang)的熔池。脈(mo)沖(chong)電(dian)(dian)(dian)流處于停歇(xie)期間(jian),點狀(zhuang)熔池冷凝,電(dian)(dian)(dian)弧(hu)由基值電(dian)(dian)(dian)流維持燃燒(shao)(輸入(ru)給焊(han)(han)(han)(han)件(jian)的能(neng)量(liang)(liang)很小(xiao)(xiao)),即(ji)以一(yi)(yi)(yi)(yi)個(ge)(ge)較小(xiao)(xiao)的基值電(dian)(dian)(dian)流來(lai)維持一(yi)(yi)(yi)(yi)個(ge)(ge)電(dian)(dian)(dian)弧(hu)的電(dian)(dian)(dian)離通(tong)道,以便下一(yi)(yi)(yi)(yi)次脈(mo)沖(chong)電(dian)(dian)(dian)流導通(tong)時(shi)(shi),脈(mo)沖(chong)電(dian)(dian)(dian)弧(hu)能(neng)可靠地(di)燃燒(shao),熔化金(jin)屬,形成一(yi)(yi)(yi)(yi)個(ge)(ge)新的焊(han)(han)(han)(han)點。只要合(he)理(li)地(di)調(diao)節間(jian)歇(xie)時(shi)(shi)間(jian)和(he)適當的焊(han)(han)(han)(han)槍移動速度,保證相(xiang)鄰兩焊(han)(han)(han)(han)點之間(jian)有(you)一(yi)(yi)(yi)(yi)定(ding)的相(xiang)互重疊量(liang)(liang),就可獲得(de)一(yi)(yi)(yi)(yi)條(tiao)連續致密的焊(han)(han)(han)(han)縫。脈(mo)沖(chong)電(dian)(dian)(dian)路原理(li)見圖4-41。

二、鎢極(ji)脈沖氬弧(hu)焊工藝特點及其適用范圍

在焊接厚度小于1mm奧氏體不銹鋼箔片和金屬軟管管坯時,若采用普通氬鎢極弧焊,焊接電流只允許用到幾安培或十幾安培。雖然所選用的鎢極直徑可以相應減小,但是電流密度仍然太小,導致鎢極局部的極斑飄移、電弧不穩;如果焊接電流調得大些,會使焊件過熱而燒穿。為了克服上述缺點,且又能保證連續焊接,在20世紀60年代研制成功了氣體保護脈沖電弧焊。它的工藝特點及其適用范圍如下。

①. 可(ke)調工藝參數多,可(ke)以(yi)(yi)精確(que)地控制待焊(han)件的(de)(de)熱輸(shu)入和熔池(chi)的(de)(de)形狀(zhuang)及(ji)尺(chi)寸。因而可(ke)提高焊(han)縫抗燒穿和熔池(chi)的(de)(de)保持(chi)能力,易(yi)獲得均勻熔深。所以(yi)(yi)特(te)別適(shi)用于(yu)薄(bo)板(ban)(薄(bo)至0.1mm)焊(han)接(jie)(jie)和全(quan)位置焊(han)接(jie)(jie)以(yi)(yi)及(ji)單面(mian)焊(han)背面(mian)成形的(de)(de)焊(han)接(jie)(jie)工藝。

②. 可以(yi)(yi)用較低的熱輸入(ru)獲得(de)較大的熔深,這樣可以(yi)(yi)減(jian)少焊接熱影響區和焊件(jian)變形。

③. 在焊接過程中,脈沖電流對(dui)點(dian)狀(zhuang)熔(rong)(rong)池有較強的攪(jiao)拌作用,而(er)且熔(rong)(rong)池金屬冷凝快,高溫停留時間短(duan),焊縫金屬組織致密(mi),可以減少敏感材料產生(sheng)裂紋的傾(qing)向。對(dui)于奧氏體不銹鋼還(huan)能(neng)(neng)提高焊接接頭的耐腐蝕性能(neng)(neng)。

④. 每個(ge)焊(han)點加(jia)熱和冷(leng)卻迅速,很適合于(yu)焊(han)接(jie)導熱性能強(qiang)或厚(hou)度特別大的焊(han)件。

⑤. 焊(han)(han)縫成形美(mei)觀,質量(liang)穩(wen)定,焊(han)(han)接接頭力學性(xing)(xing)能高于普(pu)通鎢極氬(ya)弧焊(han)(han)焊(han)(han)接接頭力學性(xing)(xing)能。

根據脈(mo)(mo)沖(chong)(chong)(chong)頻(pin)率不同,可(ke)分為低頻(pin)脈(mo)(mo)沖(chong)(chong)(chong)氬弧焊(han)和(he)高頻(pin)脈(mo)(mo)沖(chong)(chong)(chong)氬弧焊(han)。鎢極脈(mo)(mo)沖(chong)(chong)(chong)氬弧焊(han)可(ke)根據焊(han)件的(de)厚薄來選擇是(shi)否填加焊(han)絲,也可(ke)以(yi)用氦氣(qi)作為保護氣(qi)體。

三、低(di)頻(pin)脈沖(chong)氬弧焊

①. 基本原理(li)

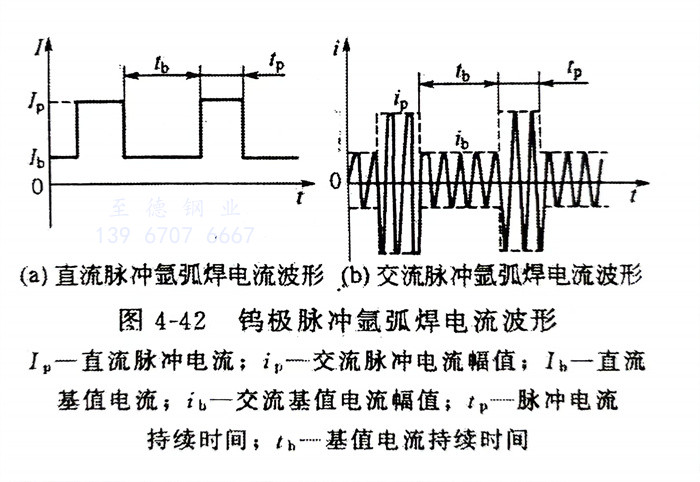

焊(han)(han)(han)(han)(han)(han)(han)接(jie)電(dian)(dian)流(liu)的(de)大小(直流(liu)電(dian)(dian)或交(jiao)流(liu)電(dian)(dian)的(de)有效值(zhi))呈(cheng)周期性(xing)脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)變(bian)化(hua)(hua),脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)的(de)頻(pin)率,從(cong)(cong)每秒接(jie)近(jin)于一次至(zhi)(zhi)幾次,至(zhi)(zhi)多(duo)不過十(shi)幾次,即以(yi)低頻(pin)脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)的(de)方法(fa)供給電(dian)(dian)流(liu)脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)。圖4-42為常見的(de)脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)電(dian)(dian)流(liu)波(bo)(bo)形,從(cong)(cong)圖中可(ke)以(yi)看(kan)出脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)焊(han)(han)(han)(han)(han)(han)(han)時(shi)(shi)的(de)電(dian)(dian)流(liu)由兩個電(dian)(dian)流(liu)組成:脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)電(dian)(dian)流(liu)和(he)基(ji)值(zhi)電(dian)(dian)流(liu);焊(han)(han)(han)(han)(han)(han)(han)接(jie)時(shi)(shi)間也(ye)是由脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)電(dian)(dian)流(liu)持(chi)續(xu)時(shi)(shi)間和(he)基(ji)值(zhi)電(dian)(dian)流(liu)持(chi)續(xu)時(shi)(shi)間兩部分組成。它(ta)們是用來(lai)調節和(he)控制焊(han)(han)(han)(han)(han)(han)(han)縫熱輸入的(de)主要(yao)參(can)數(shu)。在一個脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)電(dian)(dian)流(liu)期間,基(ji)本金(jin)屬(shu)熔化(hua)(hua)到(dao)一定的(de)熔深(shen);隨之,馬上轉變(bian)為一個小電(dian)(dian)流(liu)(基(ji)值(zhi)電(dian)(dian)流(liu)),它(ta)的(de)主要(yao)作用是維持(chi)電(dian)(dian)弧(hu)不至(zhi)(zhi)于熄滅,也(ye)提供一個熔池冷(leng)卻凝固條件、使焊(han)(han)(han)(han)(han)(han)(han)件不至(zhi)(zhi)于燒穿。其實,脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)氬弧(hu)焊(han)(han)(han)(han)(han)(han)(han)所完成的(de)連續(xu)焊(han)(han)(han)(han)(han)(han)(han)縫是由許(xu)多(duo)焊(han)(han)(han)(han)(han)(han)(han)點搭接(jie)而(er)成的(de)。焊(han)(han)(han)(han)(han)(han)(han)接(jie)電(dian)(dian)流(liu)周期性(xing)變(bian)化(hua)(hua),不僅(jin)能保證得(de)到(dao)一定的(de)熔深(shen),又不至(zhi)(zhi)于焊(han)(han)(han)(han)(han)(han)(han)穿工件,而(er)且隨著(zhu)頻(pin)率節奏(zou)可(ke)以(yi)得(de)到(dao)波(bo)(bo)紋美觀的(de)焊(han)(han)(han)(han)(han)(han)(han)縫。通過電(dian)(dian)弧(hu)脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)變(bian)化(hua)(hua),使焊(han)(han)(han)(han)(han)(han)(han)接(jie)接(jie)頭金(jin)相(xiang)組織變(bian)得(de)均勻,還(huan)細化(hua)(hua)了晶粒(li),從(cong)(cong)而(er)提高了焊(han)(han)(han)(han)(han)(han)(han)接(jie)接(jie)頭的(de)力(li)學性(xing)能和(he)耐腐蝕能力(li)。所以(yi)用脈(mo)(mo)(mo)(mo)沖(chong)(chong)(chong)氬弧(hu)焊(han)(han)(han)(han)(han)(han)(han)焊(han)(han)(han)(han)(han)(han)(han)接(jie)奧(ao)氏體型不銹鋼(gang)薄件和(he)中厚件是非常有益的(de)。

②. 工(gong)藝參數的選擇

脈(mo)(mo)(mo)沖(chong)(chong)鎢(wu)極(ji)氬弧焊的工藝參數主要有(you)脈(mo)(mo)(mo)沖(chong)(chong)電(dian)流(liu)幅(fu)值(zhi)(Ip或(huo)ip)、基(ji)值(zhi)電(dian)流(liu)(Ib或(huo)ib)、脈(mo)(mo)(mo)沖(chong)(chong)電(dian)流(liu)持續(xu)時(shi)(shi)間(jian)(tp)、基(ji)值(zhi)電(dian)流(liu)持續(xu)時(shi)(shi)間(jian)(tb),其中交(jiao)流(liu)脈(mo)(mo)(mo)沖(chong)(chong)參數ip、ib分別指脈(mo)(mo)(mo)沖(chong)(chong)電(dian)流(liu)和基(ji)值(zhi)電(dian)流(liu)在持續(xu)時(shi)(shi)間(jian)內的有(you)效值(zhi)。此外(wai)還有(you)脈(mo)(mo)(mo)幅(fu)比RA、脈(mo)(mo)(mo)寬比Rw、脈(mo)(mo)(mo)沖(chong)(chong)周(zhou)期T、脈(mo)(mo)(mo)沖(chong)(chong)頻率(lv)f,各參數之間(jian)的關(guan)系如下:

脈沖鎢(wu)極氬弧焊的工藝(yi)參(can)數,通常按(an)下述原則和步驟選擇。

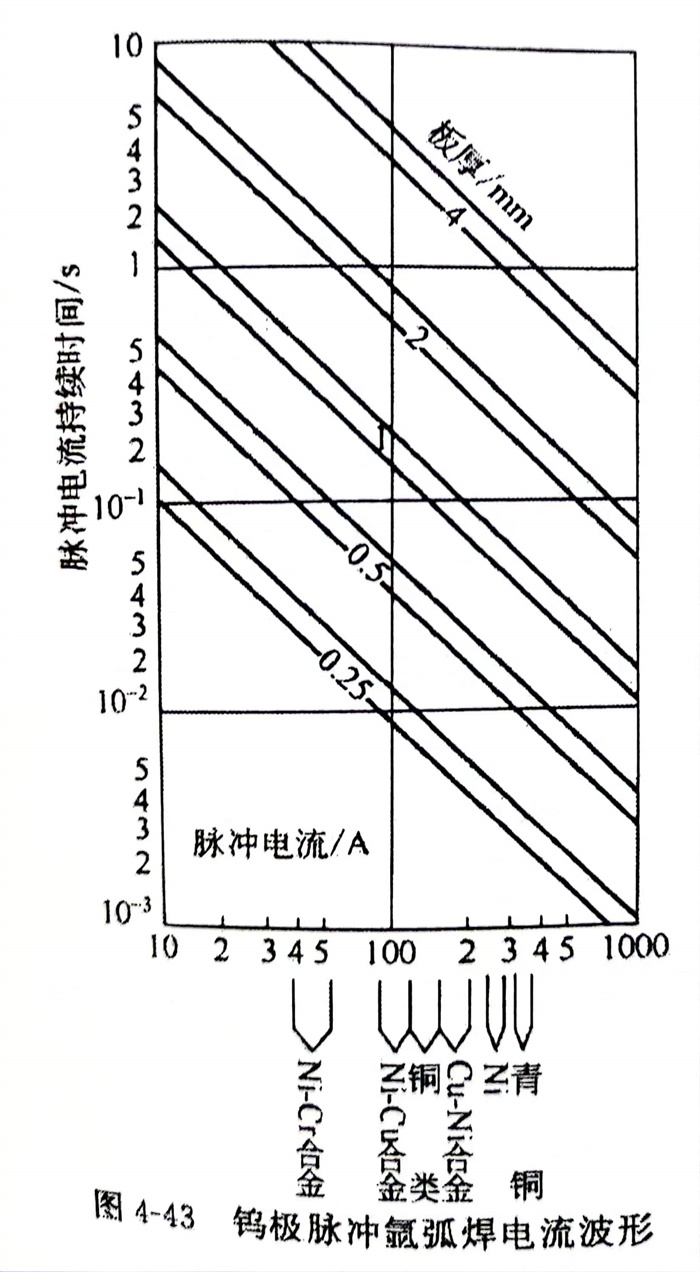

a. 對于(yu)(yu)一定的(de)(de)母(mu)材(cai)厚(hou)度(du)(du)(du),脈沖(chong)電(dian)流(liu)Ip(或ip)取決于(yu)(yu)被焊(han)母(mu)材(cai)的(de)(de)種(zhong)類,而與母(mu)材(cai)厚(hou)度(du)(du)(du)無關,所以通常先按被焊(han)材(cai)料(liao)選擇Ip(或ip),然后再按母(mu)材(cai)厚(hou)度(du)(du)(du)決定脈沖(chong)電(dian)流(liu)維持時(shi)間(jian)tp,不同材(cai)料(liao)及厚(hou)度(du)(du)(du)的(de)(de)Ip(或ip)及tp值(zhi)(zhi)(zhi)可(ke)參考(kao)圖(tu)4-43進行選擇。當焊(han)接(jie)薄件(jian)時(shi),Ip(或ip)值(zhi)(zhi)(zhi)應選低于(yu)(yu)圖(tu)示的(de)(de)數值(zhi)(zhi)(zhi),同時(shi)適當延(yan)長tp值(zhi)(zhi)(zhi);焊(han)接(jie)厚(hou)件(jian)時(shi),Ip或i,值(zhi)(zhi)(zhi)應稍高于(yu)(yu)圖(tu)示的(de)(de)數值(zhi)(zhi)(zhi),并(bing)適當縮短tp值(zhi)(zhi)(zhi)。

b. 基(ji)(ji)值(zhi)電(dian)流(liu)(liu)Ib(或ib)與基(ji)(ji)值(zhi)電(dian)流(liu)(liu)維持時(shi)間(jian)(jian)tb相(xiang)互(hu)要匹(pi)配,應(ying)保證(zheng)電(dian)弧(hu)不(bu)熄(xi)弧(hu)和熔(rong)池在基(ji)(ji)值(zhi)電(dian)流(liu)(liu)期間(jian)(jian)得以凝固。通常基(ji)(ji)值(zhi)電(dian)流(liu)(liu)Ib是(shi)脈(mo)沖電(dian)流(liu)(liu)Ip(或ip)的10%~20%,基(ji)(ji)值(zhi)電(dian)流(liu)(liu)維持時(shi)間(jian)(jian)tb為(wei)脈(mo)沖電(dian)流(liu)(liu)持續時(shi)間(jian)(jian)tp的1~3倍。

c. 脈幅比(bi)RA和脈寬(kuan)比(bi)Rw值較(jiao)大時(shi),脈沖(chong)特點較(jiao)顯著,有利于克服熱裂紋,但過(guo)大會增(zeng)加咬邊傾向。需在焊接過(guo)程(cheng)中對焊接速度進行(xing)合理調(diao)節來控制(zhi)熔透率,避(bi)免(mian)產生熱裂紋和咬邊。

d. 焊接(jie)速度(du)要(yao)和脈(mo)沖頻率(lv)相匹(pi)配,以保證焊點間(jian)距的要(yao)求,它們(men)之間(jian)的關系是:

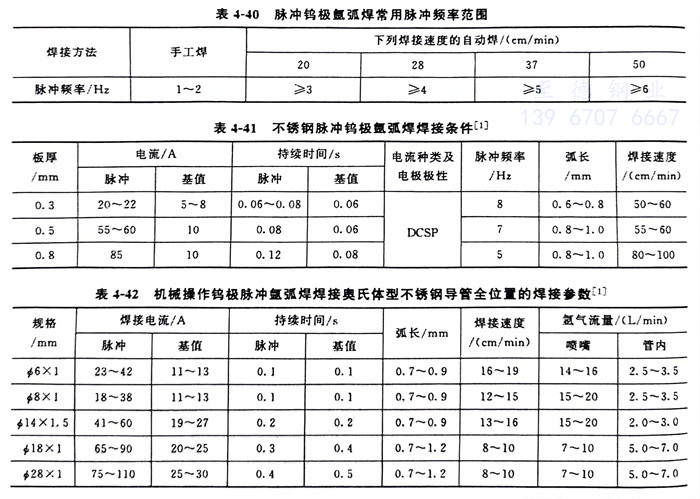

Lw 不(bu)(bu)(bu)能太大,否則焊(han)(han)點之(zhi)間無重(zhong)疊量,而得不(bu)(bu)(bu)到(dao)連續致密的焊(han)(han)縫(feng),常(chang)用頻率(lv)一(yi)般低(di)于10Hz,可參(can)考表4-40選用。不(bu)(bu)(bu)銹鋼脈(mo)沖鎢(wu)極(ji)氬弧焊(han)(han)焊(han)(han)接(jie)工藝參(can)數,可參(can)考表4-41、表4-42。

四、高(gao)頻脈沖鎢極氬(ya)弧焊(han)

高(gao)(gao)(gao)頻(pin)脈(mo)(mo)(mo)沖(chong)(chong)(chong)鎢極氬(ya)弧(hu)(hu)焊(han)(han)(han)與(yu)低頻(pin)脈(mo)(mo)(mo)沖(chong)(chong)(chong)氬(ya)弧(hu)(hu)焊(han)(han)(han)的(de)(de)不同之處,是焊(han)(han)(han)接(jie)電流以(yi)每秒鐘(zhong)幾千次(ci)甚至(zhi)幾萬次(ci)的(de)(de)極高(gao)(gao)(gao)頻(pin)率變化著。這樣的(de)(de)高(gao)(gao)(gao)頻(pin)脈(mo)(mo)(mo)沖(chong)(chong)(chong)電流使電弧(hu)(hu)的(de)(de)磁(ci)收(shou)縮效應比較強(qiang)烈,電弧(hu)(hu)直徑受到的(de)(de)壓縮更(geng)為(wei)激(ji)烈,增(zeng)強(qiang)了(le)電弧(hu)(hu)的(de)(de)挺度。同時(shi)(shi)使熔池(chi)能很好地攪拌,改(gai)善了(le)焊(han)(han)(han)縫的(de)(de)冶金(jin)(jin)性(xing)(xing)能,特(te)別適合鋁及鋁合金(jin)(jin)的(de)(de)焊(han)(han)(han)接(jie)。高(gao)(gao)(gao)頻(pin)脈(mo)(mo)(mo)沖(chong)(chong)(chong)電弧(hu)(hu)產生(sheng)的(de)(de)壓力(li)還導致超(chao)聲振(zhen)動(dong),它可(ke)以(yi)增(zeng)強(qiang)熔化金(jin)(jin)屬的(de)(de)流動(dong)性(xing)(xing)。這些(xie)都有(you)利于細(xi)化晶(jing)粒,減少焊(han)(han)(han)縫氣孔,使焊(han)(han)(han)縫成形美觀。在(zai)焊(han)(han)(han)接(jie)電流平(ping)均(jun)值相等的(de)(de)情況下,高(gao)(gao)(gao)頻(pin)脈(mo)(mo)(mo)沖(chong)(chong)(chong)鎢極氬(ya)弧(hu)(hu)焊(han)(han)(han)的(de)(de)焊(han)(han)(han)接(jie)速度可(ke)比普通鎢極氬(ya)弧(hu)(hu)焊(han)(han)(han)提高(gao)(gao)(gao)1倍,這就必然會縮短焊(han)(han)(han)縫金(jin)(jin)屬的(de)(de)高(gao)(gao)(gao)溫停(ting)留時(shi)(shi)間,對改(gai)善奧氏(shi)體型(xing)不銹鋼的(de)(de)耐蝕性(xing)(xing)是有(you)益的(de)(de)。但(dan)是,這種焊(han)(han)(han)接(jie)方法在(zai)施(shi)焊(han)(han)(han)過(guo)程(cheng)中有(you)刺耳的(de)(de)噪聲。

有(you)關脈(mo)沖鎢極氬弧焊(han)機的(de)型號很多,表4-43列出了國內(nei)幾種脈(mo)沖鎢極氬弧焊(han)機型號及其(qi)主要技術性能,可供(gong)選(xuan)用。