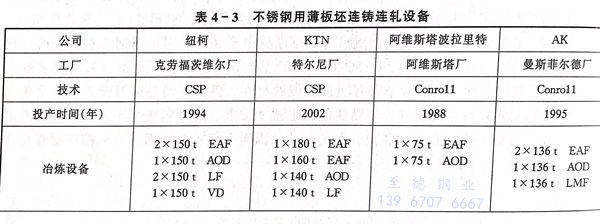

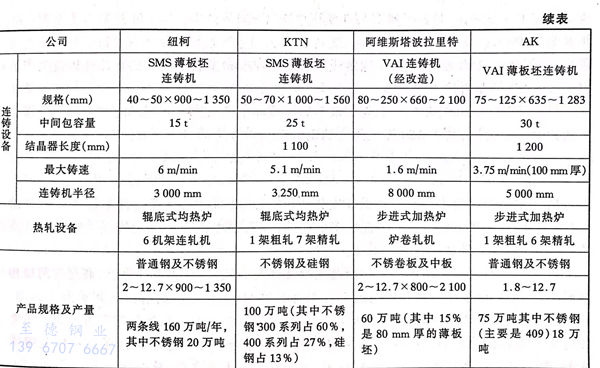

薄板坯連鑄連軋技術最早用于生產普通鋼,目的是將鋼水澆注成厚度40~127mm的薄板坯后,直接進行熱軋,這樣可以省去熱軋帶(dai)鋼的粗軋生產工序,降低生產成本,提高產品競爭力。薄板坯連鑄連軋技術1988年開始用于不銹鋼,主要有奧鋼聯(VAI)開發的Con-ro11技術和西馬克(SMS)開發的CSP技術,目前有四座工廠采用薄板坯連鑄連軋工藝生產不銹鋼(見表4-3)。

最早將(jiang)薄板(ban)(ban)(ban)(ban)坯(pi)連(lian)(lian)鑄(zhu)(zhu)(zhu)技(ji)術(shu)用(yong)(yong)于不(bu)銹(xiu)鋼(gang)(gang)的(de)(de)是(shi)(shi)(shi)阿維斯塔波拉里特公司的(de)(de)瑞典阿維斯塔工廠,當時(shi)該廠將(jiang)一臺(tai)(tai)普通(tong)的(de)(de)不(bu)銹(xiu)鋼(gang)(gang)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)由奧鋼(gang)(gang)聯公司將(jiang)板(ban)(ban)(ban)(ban)坯(pi)最小厚度140mm改(gai)(gai)造成最小厚度80mm,用(yong)(yong)以生(sheng)產高合金鋼(gang)(gang)和不(bu)銹(xiu)鋼(gang)(gang),目的(de)(de)是(shi)(shi)(shi)提高質(zhi)(zhi)量(liang)(減少偏析,鐵素體分布均勻)和避免二次軋(ya)制作(zuo)(zuo)業。連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)改(gai)(gai)造范圍(wei)是(shi)(shi)(shi)結晶器、彎曲段(duan)、弧形(xing)段(duan)和矯直(zhi)(zhi)段(duan),目前這臺(tai)(tai)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)已有15%的(de)(de)鋼(gang)(gang)水澆注成80~100mmx1400~2100mm的(de)(de)板(ban)(ban)(ban)(ban)坯(pi),并同(tong)(tong)(tong)爐卷軋(ya)機(ji)(ji)(ji)配合批(pi)量(liang)生(sheng)產不(bu)銹(xiu)鋼(gang)(gang)卷。美國AK公司的(de)(de)曼斯菲爾德廠,原(yuan)有2臺(tai)(tai)電爐,一臺(tai)(tai)AOD爐,一套熱(re)(re)連(lian)(lian)軋(ya)機(ji)(ji)(ji)(包括一架粗軋(ya)、六(liu)架精軋(ya)),1993年同(tong)(tong)(tong)奧鋼(gang)(gang)聯合作(zuo)(zuo)采用(yong)(yong)Conro11技(ji)術(shu)進(jin)(jin)行改(gai)(gai)造,新(xin)建LF爐一臺(tai)(tai),薄板(ban)(ban)(ban)(ban)坯(pi)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)一臺(tai)(tai),步(bu)(bu)進(jin)(jin)式(shi)加熱(re)(re)爐一臺(tai)(tai)及前后連(lian)(lian)接(jie)(jie)輥道(dao),新(xin)建的(de)(de)薄板(ban)(ban)(ban)(ban)坯(pi)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)為超(chao)低頭立(li)彎式(shi)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji),鋼(gang)(gang)包重(zhong)量(liang)120~160t,中間(jian)(jian)包容量(liang)30t,采用(yong)(yong)1200mm長的(de)(de)直(zhi)(zhi)結晶器,垂直(zhi)(zhi)段(duan)長2000mm,鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)總長14.6m,鑄(zhu)(zhu)(zhu)坯(pi)厚度75~125mm.該連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)出坯(pi)輥道(dao)(裝(zhuang)有保溫(wen)罩)直(zhi)(zhi)接(jie)(jie)同(tong)(tong)(tong)熱(re)(re)連(lian)(lian)軋(ya)機(ji)(ji)(ji)步(bu)(bu)進(jin)(jin)式(shi)加熱(re)(re)爐連(lian)(lian)接(jie)(jie)。該步(bu)(bu)進(jin)(jin)式(shi)加熱(re)(re)爐是(shi)(shi)(shi)把薄板(ban)(ban)(ban)(ban)坯(pi)連(lian)(lian)鑄(zhu)(zhu)(zhu)機(ji)(ji)(ji)同(tong)(tong)(tong)熱(re)(re)連(lian)(lian)軋(ya)機(ji)(ji)(ji)連(lian)(lian)接(jie)(jie)起(qi)來的(de)(de)重(zhong)要環節(jie),在發生(sheng)故障時(shi)加熱(re)(re)爐緩沖時(shi)間(jian)(jian)達1小時(shi)。從1995年4月投(tou)產以來,已順利地生(sheng)產409鐵素體不(bu)銹(xiu)鋼(gang)(gang),最高月產達到1.8萬噸,同(tong)(tong)(tong)時(shi)板(ban)(ban)(ban)(ban)坯(pi)表(biao)面質(zhi)(zhi)量(liang)良(liang)好,409不(bu)銹(xiu)鋼(gang)(gang)表(biao)面廢品率小于0.2%。

紐(niu)柯公(gong)司的(de)(de)克(ke)勞福茨維爾廠(chang)(chang)是世(shi)界上最早采用CSP技(ji)術生(sheng)產(chan)碳鋼(gang)的(de)(de)工(gong)廠(chang)(chang),為了(le)把該(gai)技(ji)術用于(yu)生(sheng)產(chan)不(bu)(bu)(bu)銹鋼(gang),1994年(nian)(nian)(nian)增設(she)(she)了(le)一臺150噸(dun)(dun)AOD精(jing)煉裝置,1995年(nian)(nian)(nian)開始生(sheng)產(chan)鐵素體不(bu)(bu)(bu)銹鋼(gang)(AISI409等),當(dang)年(nian)(nian)(nian)生(sheng)產(chan)2.16萬(wan)(wan)噸(dun)(dun),目前已達(da)到月產(chan)6000~7000t能力(li),1997年(nian)(nian)(nian)該(gai)廠(chang)(chang)又(you)同SMS集團下屬(shu)Por-Eco公(gong)司簽訂合(he)同,由(you)其(qi)(qi)改造原來(lai)的(de)(de)酸洗(xi)線,使(shi)其(qi)(qi)既能處理普(pu)通碳鋼(gang)又(you)能處理400系(xi)(xi)列不(bu)(bu)(bu)銹鋼(gang),該(gai)廠(chang)(chang)希望最終形(xing)成20萬(wan)(wan)噸(dun)(dun)不(bu)(bu)(bu)銹鋼(gang)的(de)(de)生(sheng)產(chan)規模(mo),其(qi)(qi)中409系(xi)(xi)列9.6萬(wan)(wan)噸(dun)(dun),439系(xi)(xi)列6.4萬(wan)(wan)噸(dun)(dun),304系(xi)(xi)列4萬(wan)(wan)噸(dun)(dun),值得注意(yi)的(de)(de)是KTN公(gong)司所屬(shu)的(de)(de)意(yi)大利特(te)爾尼廠(chang)(chang),在其(qi)(qi)從1992~2000年(nian)(nian)(nian)半工(gong)業(ye)試驗的(de)(de)基礎(chu)上,于(yu)2000年(nian)(nian)(nian)5月決定建設(she)(she)世(shi)界上第一臺用于(yu)生(sheng)產(chan)不(bu)(bu)(bu)銹鋼(gang)、硅鋼(gang)和碳鋼(gang)的(de)(de)CSP工(gong)廠(chang)(chang),新(xin)的(de)(de)CSP鑄機(ji)(ji)的(de)(de)主要參數(shu)如下:鑄機(ji)(ji)型式立彎式(VSB),鑄坯厚度(du)(du)70/60(mm)或60/50(mm),帶液蕊壓下,冶金長度(du)(du)9265mm,5個扇(shan)形(xing)段(duan),澆(jiao)鑄速(su)度(du)(du)5.1m/min(63mm厚時),薄板(ban)坯寬(kuan)度(du)(du)1000~1500mm,其(qi)(qi)中32%為1000mm,55%為1270mm,13%為1500mm.新(xin)的(de)(de)CSP鑄機(ji)(ji)生(sheng)產(chan)的(de)(de)薄板(ban)坯通過(guo)240m長的(de)(de)輥底式加熱爐(使(shi)板(ban)坯溫(wen)度(du)(du)均勻)和高壓水(shui)除(chu)鱗設(she)(she)備(壓力(li)400bar)直(zhi)接用現(xian)有的(de)(de)熱連軋機(ji)(ji)組生(sheng)產(chan)不(bu)(bu)(bu)銹鋼(gang)卷,鑄機(ji)(ji)生(sheng)產(chan)能力(li)達(da)100萬(wan)(wan)噸(dun)(dun)。

特別要指出的是特爾尼廠既能用現有的不銹鋼厚板坯生產,也能用薄板坯生產,熱連軋機總生產能力為180萬噸,其中150萬噸為不銹鋼。