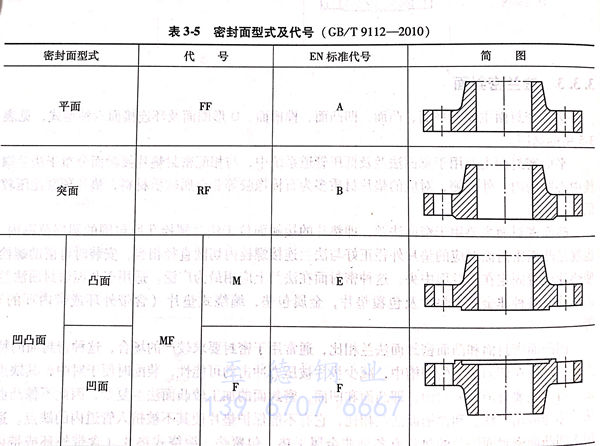

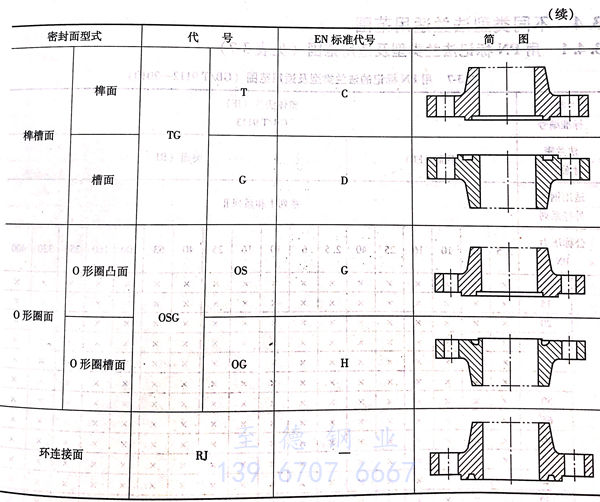

不(bu)銹(xiu)鋼法蘭密封面主要有平面、凸面、凹凸面、榫(sun)槽面、O形圈面及環連接(jie)面六種型式,見表3-5中的簡圖。

平面(mian)密封面(mian)主要用于寬面(mian)法蘭及低壓(ya)管道系統(tong)中(zhong),與相配密封(feng)墊(dian)(dian)(dian)片接(jie)觸面(mian)分(fen)布于法蘭螺栓中(zhong)心圓的內(nei)、外兩側,對應的墊(dian)(dian)(dian)片材質多為石棉(mian)橡膠等(deng)非金屬(shu)軟(ruan)質材料,墊(dian)(dian)(dian)片預緊比壓(ya)較低。

凸面密封面主(zhu)要(yao)用(yong)于(yu)窄面(mian)(mian)(mian)(mian)法(fa)蘭(lan)(lan),即墊(dian)(dian)(dian)片(pian)(pian)(pian)的(de)接(jie)觸面(mian)(mian)(mian)(mian)位于(yu)法(fa)蘭(lan)(lan)螺(luo)栓(shuan)孔所包圍(wei)的(de)圓周范圍(wei)內,也就是凸(tu)面(mian)(mian)(mian)(mian)密封(feng)面(mian)(mian)(mian)(mian)對應(ying)的(de)墊(dian)(dian)(dian)片(pian)(pian)(pian)外徑(jing)正好與法(fa)蘭(lan)(lan)連接(jie)螺(luo)栓(shuan)內切圓直徑(jing)相當,安裝時可借助螺(luo)栓(shuan)使墊(dian)(dian)(dian)片(pian)(pian)(pian)位置(zhi)固定(ding)在法(fa)蘭(lan)(lan)面(mian)(mian)(mian)(mian)中(zhong)央。這種(zhong)密封(feng)面(mian)(mian)(mian)(mian)在法(fa)蘭(lan)(lan)上應(ying)用(yong)最為廣(guang)泛。適用(yong)于(yu)凸(tu)面(mian)(mian)(mian)(mian)密封(feng)面(mian)(mian)(mian)(mian)法(fa)蘭(lan)(lan)的(de)墊(dian)(dian)(dian)片(pian)(pian)(pian)有各種(zhong)非(fei)金屬平墊(dian)(dian)(dian)片(pian)(pian)(pian)及包覆(fu)墊(dian)(dian)(dian)片(pian)(pian)(pian),金屬包墊(dian)(dian)(dian),纏繞式墊(dian)(dian)(dian)片(pian)(pian)(pian)(含帶外環或(huo)帶內環的(de))等(deng)。

凹凸面(mian)密封面(mian)和凸面(mian)(mian)(mian)(mian)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)(mian)法蘭相比(bi),通常(chang)用(yong)于密(mi)(mi)封(feng)(feng)要(yao)求較嚴的(de)(de)場合,這種(zhong)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)特(te)點是(shi)墊(dian)片(pian)(pian)嵌在凹(ao)(ao)面(mian)(mian)(mian)(mian)法蘭的(de)(de)凹(ao)(ao)槽中(zhong),減(jian)少墊(dian)片(pian)(pian)被壓力沖擊的(de)(de)可能(neng)(neng)性,裝(zhuang)配時便于對(dui)(dui)中(zhong),其缺點是(shi)一對(dui)(dui)法蘭要(yao)有兩種(zhong)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)(mian),即(ji)凸面(mian)(mian)(mian)(mian)和凹(ao)(ao)面(mian)(mian)(mian)(mian),密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)(mian)的(de)(de)加工較凸面(mian)(mian)(mian)(mian)法蘭復雜,因(yin)此不像凸面(mian)(mian)(mian)(mian)法蘭那樣(yang)應(ying)用(yong)廣(guang)泛。和榫(sun)槽面(mian)(mian)(mian)(mian)法蘭相比(bi),它有不能(neng)(neng)保護墊(dian)片(pian)(pian)使其不被擠(ji)入管道內(nei)的(de)(de)缺點。適用(yong)于凹(ao)(ao)凸面(mian)(mian)(mian)(mian)密(mi)(mi)封(feng)(feng)面(mian)(mian)(mian)(mian)法蘭的(de)(de)墊(dian)片(pian)(pian)有各種(zhong)非金屬平墊(dian)、包(bao)覆墊(dian)、纏繞(rao)式墊(dian)片(pian)(pian)(含帶外環(huan)或帶內(nei)環(huan)的(de)(de))等。

榫槽密封面(mian)具有(you)與凹凸面(mian)法(fa)蘭(lan)相似的(de)優(you)點,并優(you)于(yu)凹凸面(mian)法(fa)蘭(lan)。這種密(mi)(mi)封(feng)面(mian)的(de)法(fa)蘭(lan),與之相配的(de)墊(dian)(dian)片(pian)(pian)位于(yu)環狀凹槽(cao)內,受兩(liang)側金(jin)屬壁的(de)限制(zhi),可免于(yu)墊(dian)(dian)片(pian)(pian)受壓變(bian)形而(er)被擠(ji)入管道中。由于(yu)墊(dian)(dian)片(pian)(pian)不與管內流體(ti)(ti)介(jie)質直(zhi)接(jie)接(jie)觸,較(jiao)少(shao)遭(zao)受流體(ti)(ti)介(jie)質的(de)侵蝕或腐蝕,故可用(yong)于(yu)高壓、易燃易爆、有(you)毒(du)介(jie)質等對(dui)密(mi)(mi)封(feng)要求較(jiao)嚴的(de)場(chang)合。這種密(mi)(mi)封(feng)面(mian)對(dui)墊(dian)(dian)片(pian)(pian)安(an)裝(zhuang)對(dui)中性好(hao),但密(mi)(mi)封(feng)面(mian)加工比較(jiao)困(kun)難,更(geng)換墊(dian)(dian)片(pian)(pian)時(shi)易損傷密(mi)(mi)封(feng)面(mian),而(er)且(qie)安(an)裝(zhuang)和(he)拆卸(xie)時(shi)必須在(zai)軸向將兩(liang)法(fa)蘭(lan)分(fen)開,因(yin)此在(zai)管線設計時(shi)要考(kao)慮到有(you)將法(fa)蘭(lan)在(zai)軸向分(fen)開的(de)可能。適(shi)用(yong)于(yu)榫槽(cao)面(mian)法(fa)蘭(lan)的(de)墊(dian)(dian)片(pian)(pian)有(you)各種非(fei)金(jin)屬平墊(dian)(dian)、金(jin)屬包墊(dian)(dian)及基本型的(de)纏(chan)繞式墊(dian)(dian)片(pian)(pian)等。

O形圈面密封的(de)法(fa)(fa)蘭(lan)為一對法(fa)(fa)蘭(lan),包括O形(xing)圈(quan)凸面(mian)及O形(xing)圈(quan)槽(cao)面(mian)兩種密封面(mian),O形(xing)圈(quan)位于(yu)O形(xing)圈(quan)槽(cao)面(mian)法(fa)(fa)蘭(lan)中,靠O形(xing)圈(quan)凸面(mian)法(fa)(fa)蘭(lan)壓緊以(yi)實(shi)現(xian)密封,適(shi)用于(yu)這種密封面(mian)的(de)墊片通常(chang)為橡(xiang)膠O形(xing)密封環(huan),我國水力發(fa)電(dian)站(zhan)管道系統有(you)些采(cai)用這種密封面(mian)的(de)法(fa)(fa)蘭(lan)。

環連接面密封的(de)(de)(de)(de)法(fa)(fa)(fa)(fa)蘭(lan),也(ye)屬(shu)于窄面(mian)(mian)法(fa)(fa)(fa)(fa)蘭(lan),并在(zai)法(fa)(fa)(fa)(fa)蘭(lan)的(de)(de)(de)(de)凸面(mian)(mian)上開(kai)(kai)出一環狀梯(ti)形槽(cao)作(zuo)為(wei)法(fa)(fa)(fa)(fa)蘭(lan)密封面(mian)(mian),和榫槽(cao)面(mian)(mian)法(fa)(fa)(fa)(fa)蘭(lan)一樣,這種(zhong)法(fa)(fa)(fa)(fa)蘭(lan)在(zai)安裝(zhuang)和拆卸(xie)時必須沿軸(zhou)向將法(fa)(fa)(fa)(fa)蘭(lan)分(fen)開(kai)(kai),因此,在(zai)管線設計時要(yao)考慮到(dao)將法(fa)(fa)(fa)(fa)蘭(lan)在(zai)軸(zhou)向分(fen)開(kai)(kai)的(de)(de)(de)(de)可能(neng)。這種(zhong)密封面(mian)(mian)專門(men)用來與加(jia)工成(cheng)八角(jiao)形或(huo)橢(tuo)圓形的(de)(de)(de)(de)實(shi)體金屬(shu)墊(dian)片配(pei)合(he),以(yi)實(shi)現(xian)密封連接。由于金屬(shu)環墊(dian)可以(yi)適應(ying)各種(zhong)金屬(shu)的(de)(de)(de)(de)固(gu)有特性,因而這種(zhong)密封面(mian)(mian)的(de)(de)(de)(de)密封性能(neng)好(hao),對安裝(zhuang)要(yao)求也(ye)不太嚴格,通常適合(he)于高(gao)(gao)溫(wen)、高(gao)(gao)壓工況(kuang),但(dan)密封面(mian)(mian)的(de)(de)(de)(de)加(jia)工精度要(yao)求較(jiao)高(gao)(gao)。

1. 密(mi)封面的形式及代(dai)號

不銹(xiu)鋼法(fa)蘭密封(feng)面型式(shi)及其代號見表 3-5。

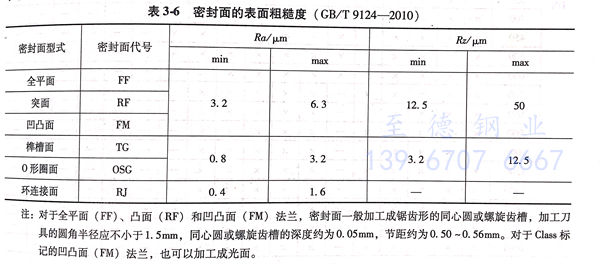

2.法蘭(lan)密(mi)封面的(de)加(jia)工

不銹鋼法蘭密(mi)(mi)封面(mian)(mian)的(de)(de)(de)(de)表面(mian)(mian)應進行(xing)機械加(jia)工,因(yin)加(jia)工表面(mian)(mian)的(de)(de)(de)(de)表面(mian)(mian)粗糙(cao)度及表面(mian)(mian)硬度(指環連接面(mian)(mian)法蘭)直接影響連接的(de)(de)(de)(de)密(mi)(mi)封性能。法蘭密(mi)(mi)封面(mian)(mian)的(de)(de)(de)(de)表面(mian)(mian)粗糙(cao)度見(jian)表3-6。用戶有特殊要(yao)求(qiu)應在訂貨合(he)同中注明。對于(yu)環連接密(mi)(mi)封面(mian)(mian)法蘭的(de)(de)(de)(de)環槽密(mi)(mi)封面(mian)(mian)的(de)(de)(de)(de)硬度應高于(yu)所配合(he)的(de)(de)(de)(de)金屬環墊的(de)(de)(de)(de)硬度。

注:對于(yu)全平面(FF)、凸(tu)面(RF)和凹(ao)凸(tu)面(FM)法蘭(lan),密封面一般加(jia)工(gong)成(cheng)(cheng)鋸齒(chi)(chi)形的同(tong)心(xin)圓(yuan)或螺(luo)旋齒(chi)(chi)槽,加(jia)工(gong)刀具的圓(yuan)角半徑(jing)應(ying)不小(xiao)于(yu)1.5mm,同(tong)心(xin)圓(yuan)或螺(luo)旋齒(chi)(chi)槽的深度約(yue)為0.05mm,節(jie)距約(yue)為0.50~0.56mm.對于(yu)Class標記的凹(ao)凸(tu)面(FM)法蘭(lan),也可(ke)以(yi)加(jia)工(gong)成(cheng)(cheng)光面。