隨著石油、天然氣、鍋爐、建筑等行業的不斷發展,在使用條件、節能降耗、產品性能等方面對不銹鋼管提出了越來越高的要求。在常規熱軋不銹(xiu)鋼管(guan)生產過程中,管坯成型歷經高溫穿孔、軋制以及定徑等工藝。產品受到圓形中空斷面形狀及生產工藝制約,缺乏更為有效的組織和性能調控手段,導致其性能提升僅能依靠添加合金元素及后續離線熱處理工序,給高品質不銹鋼管材開發以及生產成本、制造效率和能源消耗控制等帶來諸多不利影響。

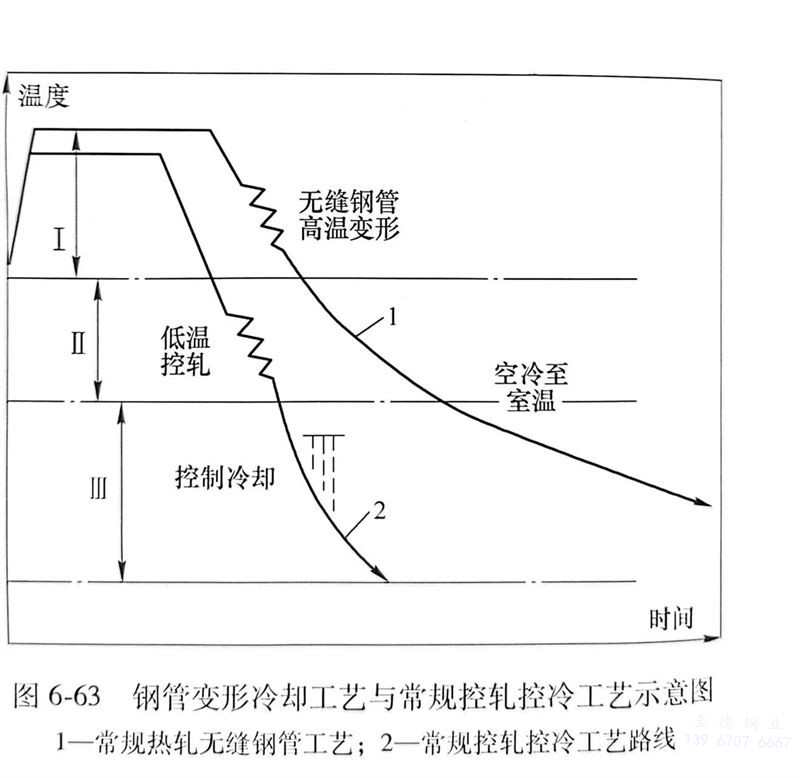

控(kong)(kong)(kong)(kong)制軋(ya)(ya)制與控(kong)(kong)(kong)(kong)制冷(leng)卻(que)工(gong)藝(yi)(yi)(控(kong)(kong)(kong)(kong)軋(ya)(ya)控(kong)(kong)(kong)(kong)冷(leng),TMCP)可綜合利用(yong)(yong)細晶強化(hua)、析(xi)出強化(hua)和(he)相變(bian)(bian)強化(hua)等強化(hua)機制,是(shi)有效在線調控(kong)(kong)(kong)(kong)熱(re)(re)軋(ya)(ya)鋼(gang)(gang)(gang)(gang)(gang)(gang)材組織、顯(xian)著提升(sheng)(sheng)材料性能(neng)的(de)重要(yao)手(shou)段。經三(san)十余年(nian)快速發展,控(kong)(kong)(kong)(kong)軋(ya)(ya)控(kong)(kong)(kong)(kong)冷(leng)技(ji)術已廣泛應用(yong)(yong)于(yu)熱(re)(re)軋(ya)(ya)板(ban)帶鋼(gang)(gang)(gang)(gang)(gang)(gang)、型鋼(gang)(gang)(gang)(gang)(gang)(gang)、棒線材等領域(yu)。然而,熱(re)(re)軋(ya)(ya)無(wu)縫鋼(gang)(gang)(gang)(gang)(gang)(gang)管有別于(yu)熱(re)(re)軋(ya)(ya)板(ban)帶鋼(gang)(gang)(gang)(gang)(gang)(gang)等鋼(gang)(gang)(gang)(gang)(gang)(gang)材門類(lei),不(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)管軋(ya)(ya)制變(bian)(bian)形(xing)和(he)成(cheng)型后的(de)冷(leng)卻(que)工(gong)藝(yi)(yi)與常規(gui)控(kong)(kong)(kong)(kong)軋(ya)(ya)控(kong)(kong)(kong)(kong)冷(leng)工(gong)藝(yi)(yi)示(shi)意(yi)圖如圖6-63所示(shi)。熱(re)(re)軋(ya)(ya)無(wu)縫鋼(gang)(gang)(gang)(gang)(gang)(gang)管高溫穿軋(ya)(ya)的(de)生產(chan)工(gong)藝(yi)(yi)條件使得控(kong)(kong)(kong)(kong)制軋(ya)(ya)制技(ji)術的(de)應用(yong)(yong)受(shou)到極大限制,環形(xing)斷面的(de)形(xing)狀特點(dian)(dian)使得控(kong)(kong)(kong)(kong)制冷(leng)卻(que)技(ji)術的(de)開(kai)發難度很(hen)大,嚴重制約了基于(yu)控(kong)(kong)(kong)(kong)軋(ya)(ya)控(kong)(kong)(kong)(kong)冷(leng)的(de)在線組織性能(neng)調控(kong)(kong)(kong)(kong)技(ji)術在該領域(yu)的(de)應用(yong)(yong)和(he)發展,熱(re)(re)軋(ya)(ya)無(wu)縫鋼(gang)(gang)(gang)(gang)(gang)(gang)管產(chan)品的(de)強度、韌性和(he)焊接性等綜合性能(neng)的(de)全面提升(sheng)(sheng)面臨瓶頸。因(yin)此(ci),實現熱(re)(re)軋(ya)(ya)不(bu)銹(xiu)鋼(gang)(gang)(gang)(gang)(gang)(gang)管的(de)成(cheng)型和(he)成(cheng)型過程的(de)在線組織性能(neng)調控(kong)(kong)(kong)(kong),是(shi)熱(re)(re)軋(ya)(ya)無(wu)縫鋼(gang)(gang)(gang)(gang)(gang)(gang)管領域(yu)長期以(yi)來的(de)重點(dian)(dian)攻關方向(xiang)之一。

針對熱(re)(re)軋(ya)不(bu)(bu)(bu)銹鋼(gang)管(guan)(guan)(guan)的(de)(de)(de)(de)(de)在(zai)線(xian)組(zu)織(zhi)(zhi)性(xing)能調(diao)控(kong)(kong)工(gong)(gong)(gong)業化(hua)技(ji)術(shu),其(qi)相關機(ji)理及(ji)(ji)(ji)核心機(ji)制(zhi)(zhi)(zhi)長期以來未取得有(you)效(xiao)(xiao)突破。首(shou)先(xian),在(zai)控(kong)(kong)制(zhi)(zhi)(zhi)軋(ya)制(zhi)(zhi)(zhi)方面(mian),由于不(bu)(bu)(bu)銹鋼(gang)管(guan)(guan)(guan)在(zai)熱(re)(re)加工(gong)(gong)(gong)過(guo)程(cheng)(cheng)中需要經歷復雜的(de)(de)(de)(de)(de)成(cheng)型工(gong)(gong)(gong)序,為降低(di)變形(xing)抗力(li)以保證軋(ya)制(zhi)(zhi)(zhi)工(gong)(gong)(gong)序的(de)(de)(de)(de)(de)穩順進(jin)行(xing),管(guan)(guan)(guan)坯(pi)的(de)(de)(de)(de)(de)加熱(re)(re)溫度往往較高,同(tong)時要在(zai)盡(jin)可能高的(de)(de)(de)(de)(de)溫度下(xia)連續完成(cheng)穿(chuan)孔及(ji)(ji)(ji)軋(ya)制(zhi)(zhi)(zhi)過(guo)程(cheng)(cheng),為此難(nan)以實現通(tong)過(guo)低(di)溫軋(ya)制(zhi)(zhi)(zhi)的(de)(de)(de)(de)(de)控(kong)(kong)制(zhi)(zhi)(zhi)軋(ya)制(zhi)(zhi)(zhi)工(gong)(gong)(gong)藝對奧氏體組(zu)織(zhi)(zhi)狀態進(jin)行(xing)調(diao)控(kong)(kong)。其(qi)次,在(zai)控(kong)(kong)制(zhi)(zhi)(zhi)冷(leng)(leng)(leng)卻(que)(que)(que)方面(mian),盡(jin)管(guan)(guan)(guan)鋼(gang)管(guan)(guan)(guan)形(xing)狀簡單(dan),但(dan)特殊(shu)的(de)(de)(de)(de)(de)環(huan)形(xing)斷面(mian)特征使(shi)得其(qi)均勻(yun)(yun)化(hua)冷(leng)(leng)(leng)卻(que)(que)(que)機(ji)制(zhi)(zhi)(zhi)顯著(zhu)區(qu)別于板帶(dai)鋼(gang)及(ji)(ji)(ji)其(qi)他類型鋼(gang)材(cai)。例(li)如,沿(yan)不(bu)(bu)(bu)銹鋼(gang)管(guan)(guan)(guan)圓周方向(xiang)均勻(yun)(yun)對稱的(de)(de)(de)(de)(de)冷(leng)(leng)(leng)卻(que)(que)(que)水布置并不(bu)(bu)(bu)能使(shi)鋼(gang)管(guan)(guan)(guan)達到均勻(yun)(yun)化(hua)的(de)(de)(de)(de)(de)冷(leng)(leng)(leng)卻(que)(que)(que)效(xiao)(xiao)果,這(zhe)其(qi)中必然存在(zai)異于傳統理念的(de)(de)(de)(de)(de)環(huan)形(xing)斷面(mian)下(xia)的(de)(de)(de)(de)(de)均勻(yun)(yun)化(hua)冷(leng)(leng)(leng)卻(que)(que)(que)機(ji)制(zhi)(zhi)(zhi)。由于鋼(gang)管(guan)(guan)(guan)的(de)(de)(de)(de)(de)均勻(yun)(yun)冷(leng)(leng)(leng)卻(que)(que)(que)機(ji)理及(ji)(ji)(ji)其(qi)控(kong)(kong)制(zhi)(zhi)(zhi)方法(fa)的(de)(de)(de)(de)(de)研究進(jin)展(zhan)有(you)限,導(dao)致(zhi)控(kong)(kong)制(zhi)(zhi)(zhi)冷(leng)(leng)(leng)卻(que)(que)(que)過(guo)程(cheng)(cheng)中的(de)(de)(de)(de)(de)組(zu)織(zhi)(zhi)性(xing)能均勻(yun)(yun)性(xing)以及(ji)(ji)(ji)冷(leng)(leng)(leng)卻(que)(que)(que)不(bu)(bu)(bu)均造成(cheng)的(de)(de)(de)(de)(de)彎管(guan)(guan)(guan)事故無法(fa)有(you)效(xiao)(xiao)解決,在(zai)較長時間制(zhi)(zhi)(zhi)約了控(kong)(kong)制(zhi)(zhi)(zhi)冷(leng)(leng)(leng)卻(que)(que)(que)技(ji)術(shu)在(zai)熱(re)(re)軋(ya)不(bu)(bu)(bu)銹鋼(gang)管(guan)(guan)(guan)領域的(de)(de)(de)(de)(de)發展(zhan)和應(ying)用。