目前采用的有(you)(you)三種(zhong)芯(xin)棒(bang)操作(zuo)方(fang)式(shi)(shi)。早期的三輥軋管(guan)機均采用全浮芯(xin)棒(bang),即(ji)使(shi)在(zai)今天(tian),仍有(you)(you)一部分機組(zu)采用全浮芯(xin)棒(bang)操作(zuo)。但是,全浮芯(xin)棒(bang)操作(zuo)方(fang)式(shi)(shi)有(you)(you)如下缺點(dian):

(1)軋制特厚(hou)壁管時不易脫棒(bang);

(2)對各種尺寸(cun)的毛管均需要配(pei)置再(zai)加熱爐(lu);

(3)軋制薄壁管(guan)時易產生的金屬扭曲和表面缺陷。由于存在上述問題導致限動芯棒和回退芯棒操作方式的開發。

以下是三種(zhong)不同(tong)芯棒(bang)操作方式的簡述。

1. 全浮芯(xin)棒

采(cai)用(yong)全(quan)浮芯(xin)(xin)(xin)棒(bang)操作方式時(shi)(shi),荒(huang)(huang)管(guan)(guan)(guan)被撥(bo)入(ru)(ru)(ru)(ru)到(dao)荒(huang)(huang)管(guan)(guan)(guan)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)前(qian)(qian)(qian)(qian)的人口臺(tai),落到(dao)和軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)中(zhong)心線一致(zhi)的U形槽里(li)。氣(qi)動(dong)壓管(guan)(guan)(guan)器壓在(zai)(zai)(zai)荒(huang)(huang)管(guan)(guan)(guan)上,將其夾緊,芯(xin)(xin)(xin)棒(bang)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)將芯(xin)(xin)(xin)棒(bang)穿(chuan)入(ru)(ru)(ru)(ru)荒(huang)(huang)管(guan)(guan)(guan)內。一旦芯(xin)(xin)(xin)棒(bang)完全(quan)穿(chuan)入(ru)(ru)(ru)(ru),壓管(guan)(guan)(guan)器就(jiu)松開,于是,荒(huang)(huang)管(guan)(guan)(guan)連同芯(xin)(xin)(xin)棒(bang)一并向(xiang)軋(ya)(ya)(ya)(ya)輥方向(xiang)送(song)去(qu)。如果荒(huang)(huang)管(guan)(guan)(guan)不易喂入(ru)(ru)(ru)(ru)軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji),就(jiu)用(yong)荒(huang)(huang)管(guan)(guan)(guan)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)在(zai)(zai)(zai)后(hou)面(mian)(mian)推(tui)(tui)下(xia),以幫助(zhu)荒(huang)(huang)管(guan)(guan)(guan)喂入(ru)(ru)(ru)(ru)。當(dang)(dang)荒(huang)(huang)管(guan)(guan)(guan)開始(shi)軋(ya)(ya)(ya)(ya)制時(shi)(shi),荒(huang)(huang)管(guan)(guan)(guan)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)和芯(xin)(xin)(xin)棒(bang)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)便返回到(dao)初始(shi)位置。但是,當(dang)(dang)采(cai)用(yong)小直徑(jing)芯(xin)(xin)(xin)棒(bang)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)時(shi)(shi),荒(huang)(huang)管(guan)(guan)(guan)推(tui)(tui)入(ru)(ru)(ru)(ru)機(ji)(ji)(ji)可(ke)保留在(zai)(zai)(zai)前(qian)(qian)(qian)(qian)位,充當(dang)(dang)導衛(wei),防止芯(xin)(xin)(xin)棒(bang)抖動(dong)。荒(huang)(huang)管(guan)(guan)(guan)延(yan)伸后(hou),荒(huang)(huang)管(guan)(guan)(guan)和芯(xin)(xin)(xin)棒(bang)一起通過軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)向(xiang)前(qian)(qian)(qian)(qian)移動(dong)軋(ya)(ya)(ya)(ya)制終了時(shi)(shi),后(hou)臺(tai)輥子升起,將毛(mao)管(guan)(guan)(guan)及芯(xin)(xin)(xin)棒(bang)送(song)到(dao)輸出(chu)(chu)輥道(dao)。然后(hou),從輸出(chu)(chu)輥送(song)到(dao)脫(tuo)棒(bang)機(ji)(ji)(ji),將芯(xin)(xin)(xin)棒(bang)從毛(mao)管(guan)(guan)(guan)中(zhong)脫(tuo)出(chu)(chu)。脫(tuo)棒(bang)后(hou),芯(xin)(xin)(xin)棒(bang)先冷卻,再(zai)送(song)到(dao)軋(ya)(ya)(ya)(ya)管(guan)(guan)(guan)機(ji)(ji)(ji)前(qian)(qian)(qian)(qian)臺(tai),以備再(zai)用(yong)。荒(huang)(huang)管(guan)(guan)(guan)則由輥道(dao)送(song)走,進行下(xia)一步加工。采(cai)用(yong)全(quan)浮棒(bang)操作方式時(shi)(shi),軋(ya)(ya)(ya)(ya)機(ji)(ji)(ji)生產率最高(gao),因(yin)此,下(xia)一根(gen)芯(xin)(xin)(xin)棒(bang)的前(qian)(qian)(qian)(qian)端實際上可(ke)以跟在(zai)(zai)(zai)正在(zai)(zai)(zai)軋(ya)(ya)(ya)(ya)制的前(qian)(qian)(qian)(qian)一根(gen)荒(huang)(huang)管(guan)(guan)(guan)的芯(xin)(xin)(xin)棒(bang)的后(hou)面(mian)(mian)。這(zhe)是可(ke)能的,因(yin)為在(zai)(zai)(zai)前(qian)(qian)(qian)(qian)一根(gen)荒(huang)(huang)管(guan)(guan)(guan)軋(ya)(ya)(ya)(ya)完以前(qian)(qian)(qian)(qian),后(hou)一根(gen)荒(huang)(huang)管(guan)(guan)(guan)可(ke)以放在(zai)(zai)(zai)前(qian)(qian)(qian)(qian)臺(tai)上、并穿(chuan)好芯(xin)(xin)(xin)棒(bang)。

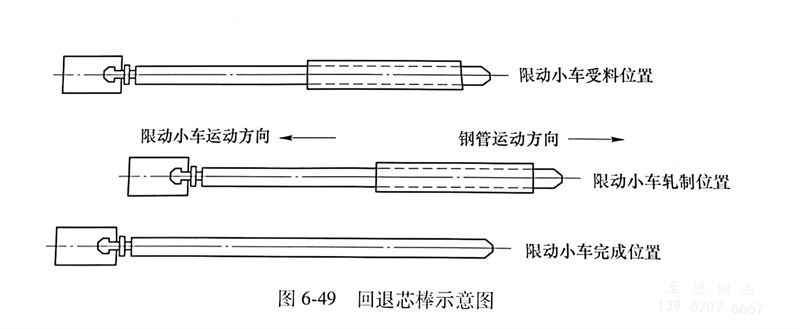

2. 回退(tui)芯棒

回(hui)退芯(xin)(xin)(xin)棒(bang)(bang)(bang)操作(zuo)(zuo)方式和浮(fu)動(dong)芯(xin)(xin)(xin)棒(bang)(bang)(bang)一(yi)樣(yang)使用同一(yi)荒(huang)管(guan)(guan)(guan)推人機(ji)(ji)與(yu)芯(xin)(xin)(xin)棒(bang)(bang)(bang)推入(ru)(ru)(ru)機(ji)(ji),但(dan)是(shi)芯(xin)(xin)(xin)棒(bang)(bang)(bang)推入(ru)(ru)(ru)機(ji)(ji)上加了一(yi)套裝置(zhi)(zhi),可(ke)將(jiang)芯(xin)(xin)(xin)棒(bang)(bang)(bang)的后端固(gu)定在芯(xin)(xin)(xin)棒(bang)(bang)(bang)推入(ru)(ru)(ru)機(ji)(ji)上并使芯(xin)(xin)(xin)棒(bang)(bang)(bang)回(hui)轉(zhuan)(zhuan)。荒(huang)管(guan)(guan)(guan)在前(qian)臺的初(chu)始(shi)位(wei)置(zhi)(zhi)和夾緊(jin)與(yu)全浮(fu)芯(xin)(xin)(xin)棒(bang)(bang)(bang)操作(zuo)(zuo)方式一(yi)樣(yang)。然而,在插(cha)入(ru)(ru)(ru)芯(xin)(xin)(xin)棒(bang)(bang)(bang)時,不(bu)僅(jin)芯(xin)(xin)(xin)棒(bang)(bang)(bang)頭部(bu)穿過荒(huang)管(guan)(guan)(guan),而且芯(xin)(xin)(xin)棒(bang)(bang)(bang)要穿過軋機(ji)(ji),伸(shen)出軋輥臺肩(jian)約3.5m。當芯(xin)(xin)(xin)棒(bang)(bang)(bang)到達此(ci)位(wei)置(zhi)(zhi)后,芯(xin)(xin)(xin)棒(bang)(bang)(bang)開(kai)始(shi)回(hui)轉(zhuan)(zhuan),直(zhi)到荒(huang)管(guan)(guan)(guan)接觸軋輥后一(yi)段時間(jian)才停止。當芯(xin)(xin)(xin)棒(bang)(bang)(bang)推入(ru)(ru)(ru)機(ji)(ji)到達行(xing)(xing)程(cheng)終點時,壓管(guan)(guan)(guan)器松開(kai),荒(huang)管(guan)(guan)(guan)推入(ru)(ru)(ru)機(ji)(ji)啟動(dong)前(qian)進(jin)。于是(shi),荒(huang)管(guan)(guan)(guan)喂入(ru)(ru)(ru)軋機(ji)(ji)。軋制開(kai)始(shi)后,芯(xin)(xin)(xin)棒(bang)(bang)(bang)開(kai)始(shi)回(hui)退。其(qi)回(hui)退速(su)度與(yu)荒(huang)管(guan)(guan)(guan)的行(xing)(xing)程(cheng)長(chang)度及前(qian)進(jin)速(su)度有(you)關,以(yi)便在軋制過程(cheng)結束,當毛管(guan)(guan)(guan)離開(kai)軋輥時,芯(xin)(xin)(xin)棒(bang)(bang)(bang)正(zheng)好從(cong)荒(huang)管(guan)(guan)(guan)中抽出。見圖6-49。然后,毛管(guan)(guan)(guan)從(cong)軋機(ji)(ji)運走(zou),進(jin)行(xing)(xing)下(xia)步(bu)加工(gong),而芯(xin)(xin)(xin)棒(bang)(bang)(bang)高速(su)返回(hui)其(qi)初(chu)始(shi)位(wei)置(zhi)(zhi)以(yi)備穿入(ru)(ru)(ru)下(xia)一(yi)根毛管(guan)(guan)(guan)。

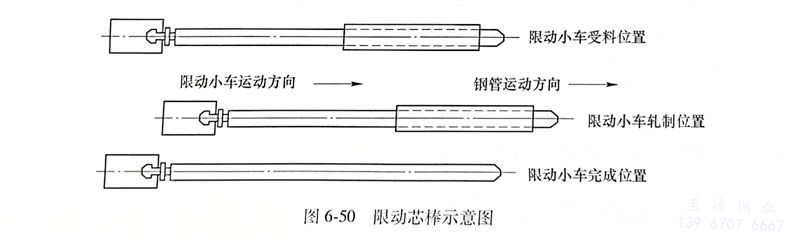

3. 限動(dong)芯棒(bang)

限動芯(xin)(xin)(xin)(xin)棒(bang)(bang)操(cao)(cao)作(zuo)法是全浮芯(xin)(xin)(xin)(xin)棒(bang)(bang)和回(hui)退芯(xin)(xin)(xin)(xin)棒(bang)(bang)操(cao)(cao)作(zuo)法的折中方法。采用這種方法時(shi),芯(xin)(xin)(xin)(xin)棒(bang)(bang)的尾(wei)端(duan)固定在芯(xin)(xin)(xin)(xin)棒(bang)(bang)推(tui)入(ru)機上(shang),并可(ke)回(hui)轉(zhuan)。這和回(hui)退芯(xin)(xin)(xin)(xin)棒(bang)(bang)操(cao)(cao)作(zuo)方式一樣,不同(tong)的是,鋼(gang)管(guan)(guan)軋制時(shi)芯(xin)(xin)(xin)(xin)棒(bang)(bang)向(xiang)前(qian)移動。在軋制結束時(shi),芯(xin)(xin)(xin)(xin)棒(bang)(bang)從毛管(guan)(guan)上(shang)脫出(chu)。當荒(huang)管(guan)(guan)在前(qian)臺被夾緊(jin)時(shi),穿入(ru)芯(xin)(xin)(xin)(xin)棒(bang)(bang),直(zhi)到(dao)芯(xin)(xin)(xin)(xin)棒(bang)(bang)前(qian)端(duan)伸出(chu)軋輥臺肩約0.3m左右為(wei)止。插入(ru)芯(xin)(xin)(xin)(xin)棒(bang)(bang)時(shi),芯(xin)(xin)(xin)(xin)棒(bang)(bang)開(kai)(kai)始回(hui)轉(zhuan),直(zhi)到(dao)荒(huang)管(guan)(guan)接觸軋輥后一段(duan)時(shi)間才停止。芯(xin)(xin)(xin)(xin)棒(bang)(bang)到(dao)位(wei)后,壓管(guan)(guan)器松開(kai)(kai),荒(huang)管(guan)(guan)推(tui)入(ru)機將荒(huang)管(guan)(guan)推(tui)向(xiang)軋輥,直(zhi)到(dao)軋制過程開(kai)(kai)始為(wei)止。軋制過程中,芯(xin)(xin)(xin)(xin)捧以低于毛管(guan)(guan)軸向(xiang)輸(shu)出(chu)速度的速度和軋件(jian)一起前(qian)進。軋制周期結束時(shi),毛管(guan)(guan)從芯(xin)(xin)(xin)(xin)棒(bang)(bang)上(shang)脫出(chu),然(ran)后,芯(xin)(xin)(xin)(xin)棒(bang)(bang)高速返回(hui)其初(chu)始位(wei)置。

三(san)種芯(xin)(xin)棒(bang)(bang)(bang)操(cao)作(zuo)方(fang)(fang)(fang)式(shi)的(de)比較。在采用回退芯(xin)(xin)棒(bang)(bang)(bang)與(yu)限動(dong)芯(xin)(xin)棒(bang)(bang)(bang)操(cao)作(zuo)方(fang)(fang)(fang)式(shi)的(de)工廠,只有生產(chan)D/t小于(yu)7.5的(de)鋼管(guan)時(shi)(shi)才采用回退芯(xin)(xin)棒(bang)(bang)(bang)操(cao)作(zuo)方(fang)(fang)(fang)式(shi),而當生產(chan)D/t大于(yu)7.5的(de)鋼管(guan)時(shi)(shi)采用限動(dong)芯(xin)(xin)棒(bang)(bang)(bang)操(cao)作(zuo)方(fang)(fang)(fang)式(shi)。顯然(ran),采用回退和限動(dong)芯(xin)(xin)棒(bang)(bang)(bang)操(cao)作(zuo)方(fang)(fang)(fang)式(shi)時(shi)(shi),軋機產(chan)量比采用全(quan)浮芯(xin)(xin)棒(bang)(bang)(bang)時(shi)(shi)低(di),因為(wei),下一根荒管(guan)撥入到前臺之前,在用的(de)芯(xin)(xin)棒(bang)(bang)(bang)必須返(fan)回其初始(shi)位置。同時(shi)(shi),芯(xin)(xin)棒(bang)(bang)(bang)的(de)冷卻不充分,芯(xin)(xin)棒(bang)(bang)(bang)壽(shou)命不長。