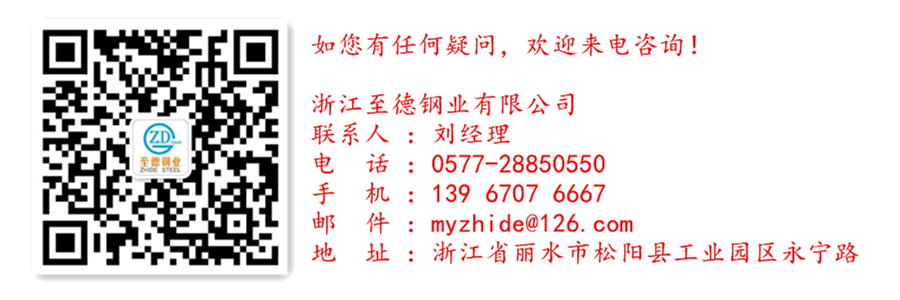

將板、帶鋼在輥式冷彎成型機上,經若干架次相對旋轉的成型輥(水平輥、立輥、組合輥)連續彎曲變形以得到要求的形狀尺寸的冷彎型鋼的過程稱為輥式冷彎成型。輥式冷彎成型是金屬壓力加工工藝的一種,其成型過程如圖5-9所示。平板坯的特定部位經漸次彎曲成角度a2、a2、α3、···an,最后成為所要求的斷面。輥式冷彎成型與型鋼熱軋不同之處是,其各道次金屬橫截面積從理論上可視為不變。這種變形也不同于非穩態變形的沖壓成型,從一個角度彎至下一道的某一角度,在板坯全長上不是同時成型的,而是經過一個平緩過渡后,逐漸彎成需要的角度。

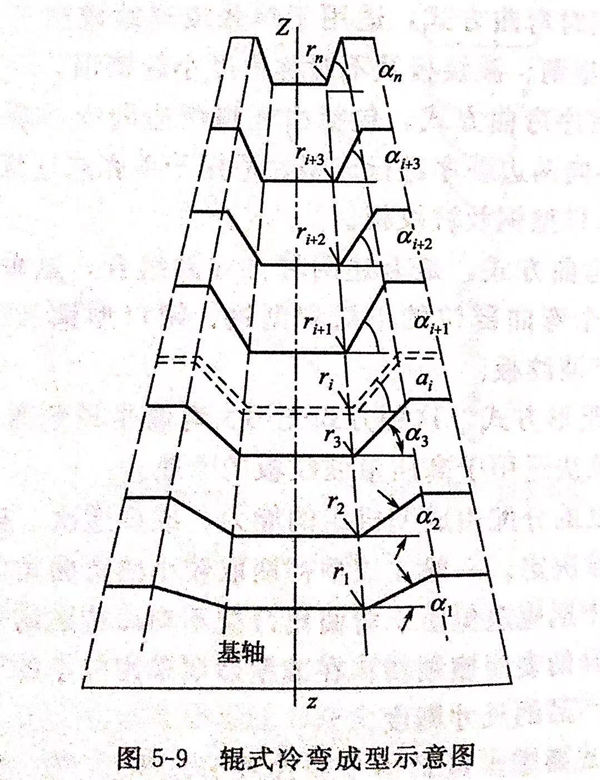

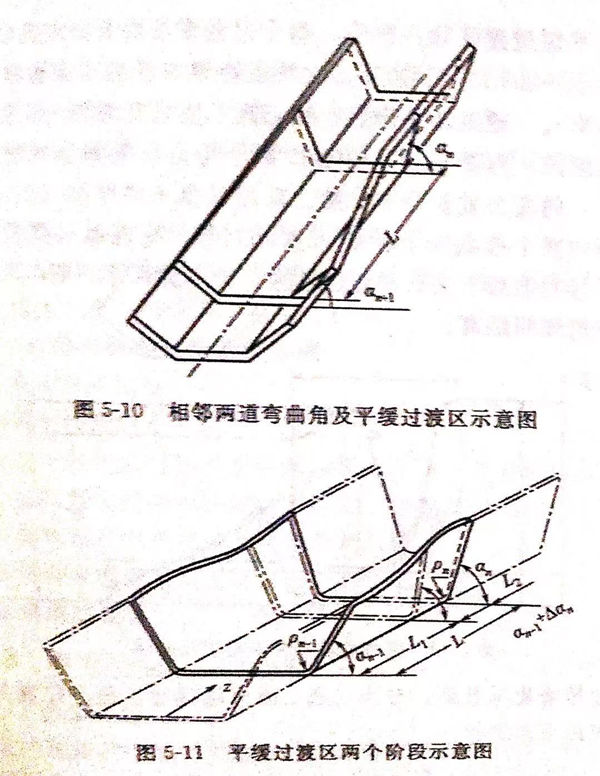

輥(gun)(gun)式冷彎(wan)(wan)(wan)成(cheng)型(xing)(xing)(xing)和普(pu)通(tong)(tong)軋(ya)(ya)(ya)(ya)(ya)(ya)制過(guo)(guo)(guo)程一(yi)樣,冷彎(wan)(wan)(wan)成(cheng)型(xing)(xing)(xing)時(shi)(shi)帶坯(pi)任意斷面(mian)(mian)上(shang)的(de)(de)金(jin)屬流動(dong)是穩定(ding)的(de)(de),不(bu)隨時(shi)(shi)間(jian)而變(bian)(bian)化,相鄰(lin)兩(liang)(liang)道(dao)次之(zhi)(zhi)間(jian)帶坯(pi)進(jin)入(ru)(ru)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)位置,如圖5-10所(suo)示,彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)角(jiao)由(you)(you)上(shang)一(yi)道(dao)次的(de)(de)αn-1增(zeng)大(da)(da)(da)到下(xia)一(yi)道(dao)次的(de)(de)αn,彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)圓弧半(ban)徑由(you)(you)rn-1,減小(xiao)為(wei)(wei)rn.由(you)(you)于板(ban)坯(pi)前(qian)(qian)(qian)端(duan)部(bu)上(shang)拾,彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)角(jiao)增(zeng)大(da)(da)(da),而產生的(de)(de)張力(li)(li)作(zuo)(zuo)用(yong)于邊(bian)(bian)部(bu),在相對旋轉的(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)的(de)(de)作(zuo)(zuo)用(yong)下(xia),板(ban)帶坯(pi)沿軋(ya)(ya)(ya)(ya)(ya)(ya)制方向前(qian)(qian)(qian)進(jin)并實現(xian)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)變(bian)(bian)形(xing)(xing)。實現(xian)板(ban)坯(pi)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)變(bian)(bian)形(xing)(xing)的(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)工作(zuo)(zuo)部(bu)分(fen)稱為(wei)(wei)軋(ya)(ya)(ya)(ya)(ya)(ya)槽(輥(gun)(gun)槽),由(you)(you)兩(liang)(liang)個和兩(liang)(liang)個以(yi)上(shang)通(tong)(tong)過(guo)(guo)(guo)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)所(suo)構(gou)成(cheng)的(de)(de)軋(ya)(ya)(ya)(ya)(ya)(ya)槽斷面(mian)(mian)變(bian)(bian)形(xing)(xing)區(qu)稱為(wei)(wei)孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)。因此,輥(gun)(gun)式冷彎(wan)(wan)(wan)成(cheng)型(xing)(xing)(xing)亦(yi)可視為(wei)(wei)板(ban)坯(pi)經若干孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)實現(xian)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)的(de)(de)穩態變(bian)(bian)形(xing)(xing)過(guo)(guo)(guo)程。從上(shang)一(yi)道(dao)輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)(孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing))到下(xia)一(yi)道(dao)輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)(孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing))間(jian)距離L稱為(wei)(wei)平(ping)(ping)緩(huan)過(guo)(guo)(guo)渡(du)(du)區(qu)長(chang)度。L的(de)(de)大(da)(da)(da)小(xiao)與(yu)機架間(jian)距有(you)關,L愈(yu)(yu)大(da)(da)(da)變(bian)(bian)形(xing)(xing)愈(yu)(yu)緩(huan)和。而平(ping)(ping)緩(huan)過(guo)(guo)(guo)渡(du)(du)區(qu)又可細分(fen)為(wei)(wei)L1和L2兩(liang)(liang)個區(qu)(見(jian)圖5-11).板(ban)坯(pi)從前(qian)(qian)(qian)道(dao)孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)(對應(ying)(ying)(ying)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)角(jiao)an-1)進(jin)入(ru)(ru)下(xia)道(dao)孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)(對應(ying)(ying)(ying)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)角(jiao)αn),開(kai)(kai)始時(shi)(shi)坯(pi)料(liao)(liao)前(qian)(qian)(qian)端(duan)部(bu)分(fen)與(yu)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)下(xia)軋(ya)(ya)(ya)(ya)(ya)(ya)槽接(jie)觸,在坯(pi)料(liao)(liao)中形(xing)(xing)成(cheng)數值不(bu)大(da)(da)(da)的(de)(de)彈(dan)性(xing)應(ying)(ying)(ying)力(li)(li)。軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)前(qian)(qian)(qian)行(xing)與(yu)上(shang)軋(ya)(ya)(ya)(ya)(ya)(ya)槽接(jie)觸,在上(shang)下(xia)軋(ya)(ya)(ya)(ya)(ya)(ya)槽作(zuo)(zuo)用(yong)下(xia)產生塑(su)性(xing)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu),即板(ban)坯(pi)在輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)前(qian)(qian)(qian)(未通(tong)(tong)過(guo)(guo)(guo)an孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing))已開(kai)(kai)始了塑(su)性(xing)彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)變(bian)(bian)形(xing)(xing),原(yuan)(yuan)來(lai)平(ping)(ping)直的(de)(de)邊(bian)(bian)部(bu)產生縱向扭曲(qu)(qu)(qu)(qu),形(xing)(xing)成(cheng)復雜的(de)(de)曲(qu)(qu)(qu)(qu)線(xian)表面(mian)(mian)。坯(pi)料(liao)(liao)的(de)(de)橫截面(mian)(mian)形(xing)(xing)狀逐(zhu)漸按(an)孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)輪廓(kuo)形(xing)(xing)狀變(bian)(bian)化。彎(wan)(wan)(wan)折(zhe)處金(jin)屬連續經受(shou)彈(dan)性(xing)到彈(dan)塑(su)性(xing)變(bian)(bian)形(xing)(xing)。隨彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)角(jiao)增(zeng)大(da)(da)(da),彎(wan)(wan)(wan)曲(qu)(qu)(qu)(qu)圓弧半(ban)徑減小(xiao),彎(wan)(wan)(wan)折(zhe)處切向正應(ying)(ying)(ying)力(li)(li)和彎(wan)(wan)(wan)矩(ju)增(zeng)加,在板(ban)坯(pi)料(liao)(liao)前(qian)(qian)(qian)端(duan)已變(bian)(bian)形(xing)(xing)部(bu)分(fen)與(yu)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)壓緊軋(ya)(ya)(ya)(ya)(ya)(ya)件(jian)的(de)(de)共同作(zuo)(zuo)用(yong)下(xia),板(ban)坯(pi)邊(bian)(bian)部(bu)出(chu)現(xian)拉應(ying)(ying)(ying)力(li)(li),引起邊(bian)(bian)部(bu)拉伸,板(ban)坯(pi)通(tong)(tong)過(guo)(guo)(guo)軋(ya)(ya)(ya)(ya)(ya)(ya)輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)之(zhi)(zhi)后(hou)(通(tong)(tong)過(guo)(guo)(guo)孔(kong)(kong)(kong)(kong)型(xing)(xing)(xing)后(hou)),原(yuan)(yuan)來(lai)產生縱向扭曲(qu)(qu)(qu)(qu)的(de)(de)邊(bian)(bian)部(bu)被拉平(ping)(ping),輥(gun)(gun)軸(zhou)(zhou)(zhou)(zhou)平(ping)(ping)面(mian)(mian)前(qian)(qian)(qian)變(bian)(bian)形(xing)(xing)區(qu)長(chang)度不(bu)再增(zeng)加而保持長(chang)度不(bu)變(bian)(bian)(L)。

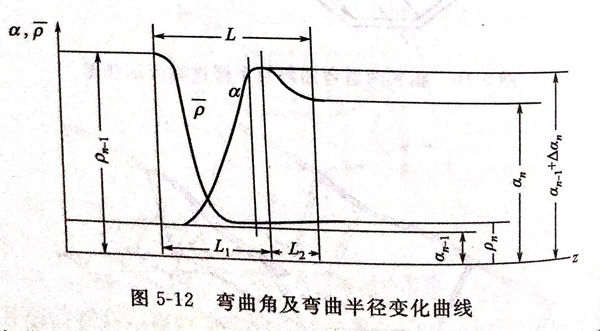

這是平緩過渡區第一階段,整個過程中彎曲角單方向增大(從(an-1增至an+Δan),見圖5-12,并且坯料中性層彎曲圓弧半徑從rn-1減小至rn.通過軸平面后,變形區長度仍有增加,形成平緩過渡區第二階段,彎曲角從an+Δan減小為αn.坯料前端出現彈性變形特征,內應力重新分布,第二階段長度不再增加(L2),在此長度范圍內整個橫截面上內應力彼此相等,呈現第一類殘應力特征。成型過程繼續下去,平緩過渡區保持形狀尺寸不變,其長度通常小于兩機架間距離。

彎曲角變化呈S形,分為三段。在平緩過渡區任一位置上彎曲角大小可用下式表示.

坯料橫截面(mian)各個直線(xian)部分受(shou)(shou)縱向(xiang)拉伸或(huo)壓縮變(bian)形(xing),與之相(xiang)鄰(lin)的(de)曲線(xian)部分受(shou)(shou)彎(wan)曲變(bian)形(xing),弄(nong)清板坯在(zai)相(xiang)鄰(lin)兩道次間彎(wan)曲變(bian)形(xing)行為,對于制定成型(xing)方(fang)案和設計孔型(xing)具(ju)有一定的(de)意義。

為將(jiang)板帶材經連(lian)續輥彎(wan)變形加工(gong)成合格冷(leng)(leng)彎(wan)型(xing)鋼而(er)進行的成型(xing)方法及工(gong)具的設計稱為冷(leng)(leng)彎(wan)成型(xing)輥孔型(xing)設計。冷(leng)(leng)彎(wan)成型(xing)輥孔型(xing)設計的依據是:冷(leng)(leng)彎(wan)型(xing)材產(chan)品標準、成型(xing)材料的性能、技(ji)術要求(qiu)、生產(chan)機組配置及主要參數。

1. 孔型(xing)設計的要求

①. 能(neng)夠生(sheng)產出符合技(ji)術要求(qiu)的產品斷面形狀及尺寸精度。

②. 產品在全長上無水平垂直瓢曲及縱向扭轉。

③. 彎折處減薄(bo)及斷面殘余應力最小,產品無邊波、皺折及裂紋。

④. 金屬出人孔型順(shun)利,軋輥安裝調整方便(bian)。

⑤. 孔型組合配(pei)置合理、孔型磨損小、輥耗(hao)低、能耗(hao)小。

⑥. 操作方(fang)便,可達最大機組(zu)生(sheng)產率。

2. 冷彎成型輥孔型設計(ji)步驟

①. 確定坯料寬度。

②. 確定型鋼對(dui)水平輥中心(xin)線的位置。

③. 選擇(ze)型鋼成(cheng)型基本中(zhong)心線(xian)(簡稱基軸)及基準線(xian)段。

④. 確定型鋼(gang)過渡斷面數(shu)量和形狀(俗稱(cheng)花形圖(tu))。

⑤. 畫斷面配輥圖和單個軋輥及輥片圖。

⑥. 導(dao)衛(wei)及(ji)輔(fu)助(zhu)工(gong)具設(she)計及(ji)圖紙(zhi)的繪制。

⑦. 必要(yao)的校核。