薄帶連鑄是把鋼水直接澆鑄成厚度為1~10mm的帶鋼,采用這種新技術生產帶鋼可以省去傳統的生產熱軋帶鋼(gang)的熱連軋機(或爐卷軋機),可以大大降能耗,減少污染,降低生產成本,從而實現最佳的經濟效益。

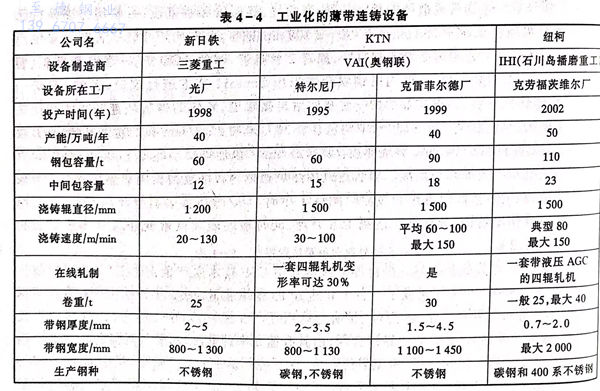

薄(bo)帶(dai)(dai)連(lian)(lian)(lian)(lian)鑄(zhu)的(de)(de)(de)原(yuan)理(li)(li)是鋼(gang)(gang)(gang)水(shui)(shui)通過中間(jian)包進(jin)入(ru)連(lian)(lian)(lian)(lian)鑄(zhu)機(ji)(ji),該連(lian)(lian)(lian)(lian)鑄(zhu)機(ji)(ji)沒有(you)結(jie)晶器,而是有(you)兩根(gen)相對旋轉的(de)(de)(de)澆(jiao)(jiao)鑄(zhu)輥,鋼(gang)(gang)(gang)水(shui)(shui)通過澆(jiao)(jiao)鑄(zhu)輥組(zu)成彎月面(mian)開始凝固(gu),隨著坯(pi)子通過輥縫間(jian)隙向(xiang)下(xia)運(yun)動,坯(pi)殼(ke)(ke)不斷長大,并使(shi)兩面(mian)坯(pi)殼(ke)(ke)完(wan)全(quan)熔合(he)在(zai)一起形成連(lian)(lian)(lian)(lian)續的(de)(de)(de)薄(bo)帶(dai)(dai)鋼(gang)(gang)(gang),從連(lian)(lian)(lian)(lian)鑄(zhu)機(ji)(ji)下(xia)方(fang)出來。盡管薄(bo)帶(dai)(dai)連(lian)(lian)(lian)(lian)鑄(zhu)的(de)(de)(de)原(yuan)理(li)(li)比較簡單,但要將(jiang)其運(yun)用于工(gong)(gong)業(ye)生產(chan)十分(fen)困難。近年來由(you)于在(zai)一些關鍵領域中的(de)(de)(de)技(ji)術(shu)突破,例如鋼(gang)(gang)(gang)水(shui)(shui)進(jin)入(ru)連(lian)(lian)(lian)(lian)鑄(zhu)機(ji)(ji)技(ji)術(shu)(主要在(zai)水(shui)(shui)口上作文章,減(jian)少鋼(gang)(gang)(gang)水(shui)(shui)擾動,并使(shi)鋼(gang)(gang)(gang)水(shui)(shui)沿輥身有(you)效分(fen)布),初(chu)期凝固(gu)技(ji)術(shu)(解決表面(mian)質量),澆(jiao)(jiao)鑄(zhu)輥側封材料,輥子變形和耐火材料等,使(shi)薄(bo)帶(dai)(dai)連(lian)(lian)(lian)(lian)鑄(zhu)技(ji)術(shu)逐步從中間(jian)試驗走向(xiang)工(gong)(gong)業(ye)化,目前世界上已(yi)有(you)4臺工(gong)(gong)業(ye)化的(de)(de)(de)薄(bo)帶(dai)(dai)連(lian)(lian)(lian)(lian)鑄(zhu)機(ji)(ji),其主要參數(shu)見表4-4,相信在(zai)不遠(yuan)的(de)(de)(de)將(jiang)來用薄(bo)板帶(dai)(dai)連(lian)(lian)(lian)(lian)鑄(zhu)技(ji)術(shu)生產(chan)不銹鋼(gang)(gang)(gang)將(jiang)成為現實。