超聲探傷儀、超聲波探頭、測試塊和耦合劑等是超聲檢測系統的重要組成部分。超聲波檢測的主要設備是超聲波探傷儀,它可以快速、方便、無損傷地檢測、定位、評估和診斷工件中的各種缺陷。由于超聲波探頭可實現電聲轉換,所以超聲波探頭也叫超聲波換能器,其電聲轉換是可逆的,且轉換時間極短,可以忽略不計。根據超聲波的產生方式和電聲轉換的不同,超聲波換能器有很多種。這些電聲轉換方式有:利用某些金屬(鐵磁性材料)在交變磁場中的磁致伸縮,產生和接收超聲波;利用電磁感應原理產生電磁超聲以及利用機械振動、熱效應和靜電法等都能產生和接收超聲波,利用壓電效應原理制成的壓電材料是目前用得最多的超聲換能器。

1. 壓(ya)電效(xiao)應

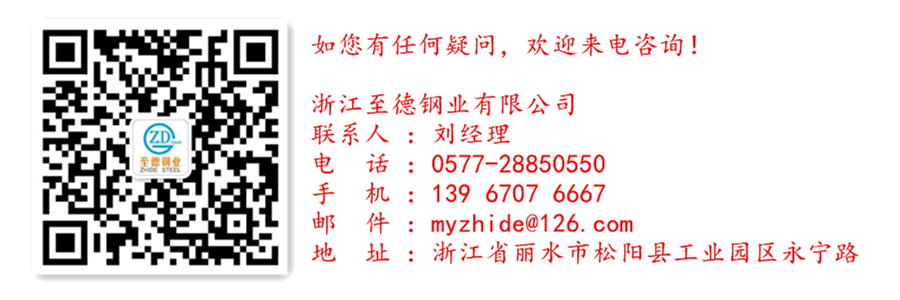

有一(yi)種(zhong)晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti),當(dang)(dang)受到擠壓(ya)或者拉(la)伸(shen)作(zuo)(zuo)用(yong)(yong)力的(de)(de)時候,產生形(xing)變,使得其中的(de)(de)帶電(dian)(dian)(dian)(dian)(dian)質點發生相對位(wei)移(yi),因此大小(xiao)相等極性相反的(de)(de)正電(dian)(dian)(dian)(dian)(dian)荷(he)和負(fu)電(dian)(dian)(dian)(dian)(dian)荷(he)會(hui)出現(xian)(xian)在(zai)晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)表(biao)面,然后(hou)(hou)在(zai)兩(liang)端產生不同的(de)(de)電(dian)(dian)(dian)(dian)(dian)荷(he),此時晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)將處于(yu)(yu)(yu)帶電(dian)(dian)(dian)(dian)(dian)狀態(tai),并且由作(zuo)(zuo)用(yong)(yong)力產生的(de)(de)電(dian)(dian)(dian)(dian)(dian)荷(he)量與(yu)作(zuo)(zuo)用(yong)(yong)力的(de)(de)大小(xiao)成正比;當(dang)(dang)作(zuo)(zuo)用(yong)(yong)力撤去(qu)之后(hou)(hou),晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)恢(hui)復到它的(de)(de)中性狀態(tai),這種(zhong)現(xian)(xian)象(xiang)被(bei)稱(cheng)作(zuo)(zuo)正壓(ya)電(dian)(dian)(dian)(dian)(dian)效(xiao)應(ying)(ying)。當(dang)(dang)此類晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)處于(yu)(yu)(yu)電(dian)(dian)(dian)(dian)(dian)場中時,晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)會(hui)沿一(yi)定的(de)(de)方向產生機械形(xing)變;電(dian)(dian)(dian)(dian)(dian)場撤去(qu)之后(hou)(hou)形(xing)變消(xiao)失(shi),晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)恢(hui)復原狀,這種(zhong)現(xian)(xian)象(xiang)被(bei)稱(cheng)為逆壓(ya)電(dian)(dian)(dian)(dian)(dian)效(xiao)應(ying)(ying)或電(dian)(dian)(dian)(dian)(dian)致伸(shen)縮效(xiao)應(ying)(ying)。正壓(ya)電(dian)(dian)(dian)(dian)(dian)效(xiao)應(ying)(ying)與(yu)逆壓(ya)電(dian)(dian)(dian)(dian)(dian)效(xiao)應(ying)(ying)被(bei)統(tong)稱(cheng)為壓(ya)電(dian)(dian)(dian)(dian)(dian)效(xiao)應(ying)(ying),如圖3.1所示。這種(zhong)物理(li)現(xian)(xian)象(xiang)在(zai)1880年被(bei)居里兄(xiong)弟發現(xian)(xian),正是由于(yu)(yu)(yu)這種(zhong)現(xian)(xian)象(xiang),壓(ya)電(dian)(dian)(dian)(dian)(dian)晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)被(bei)廣(guang)泛應(ying)(ying)用(yong)(yong)于(yu)(yu)(yu)產生超聲波(bo)的(de)(de)晶(jing)(jing)(jing)(jing)(jing)體(ti)(ti)(ti)振蕩(dang)器。

壓(ya)(ya)電(dian)(dian)效應(ying)(ying)的原理是(shi),如果對壓(ya)(ya)電(dian)(dian)材料(liao)施(shi)加壓(ya)(ya)力,就會(hui)(hui)產(chan)(chan)生(sheng)(sheng)(sheng)電(dian)(dian)位差(cha)(稱為正壓(ya)(ya)電(dian)(dian)效應(ying)(ying)),反之(zhi)(zhi)施(shi)加電(dian)(dian)壓(ya)(ya)時,會(hui)(hui)產(chan)(chan)生(sheng)(sheng)(sheng)機(ji)(ji)(ji)械(xie)應(ying)(ying)力(稱為逆壓(ya)(ya)電(dian)(dian)效應(ying)(ying))。如果壓(ya)(ya)力是(shi)高(gao)頻(pin)振動,就會(hui)(hui)產(chan)(chan)生(sheng)(sheng)(sheng)高(gao)頻(pin)電(dian)(dian)流。當高(gao)頻(pin)電(dian)(dian)信(xin)號(hao)(hao)(hao)應(ying)(ying)用(yong)(yong)于壓(ya)(ya)電(dian)(dian)陶瓷上時,會(hui)(hui)產(chan)(chan)生(sheng)(sheng)(sheng)高(gao)頻(pin)聲信(xin)號(hao)(hao)(hao)(機(ji)(ji)(ji)械(xie)振動),通常(chang)稱為超(chao)聲信(xin)號(hao)(hao)(hao)。也就是(shi)說,壓(ya)(ya)電(dian)(dian)晶片可(ke)以(yi)因機(ji)(ji)(ji)械(xie)形變產(chan)(chan)生(sheng)(sheng)(sheng)電(dian)(dian)場,也可(ke)以(yi)因電(dian)(dian)場的作用(yong)(yong)產(chan)(chan)生(sheng)(sheng)(sheng)機(ji)(ji)(ji)械(xie)形變,實現機(ji)(ji)(ji)械(xie)能與(yu)電(dian)(dian)能之(zhi)(zhi)間的轉換和逆轉換,這種內在的機(ji)(ji)(ji)電(dian)(dian)耦合效應(ying)(ying)使得壓(ya)(ya)電(dian)(dian)晶體在工(gong)程(cheng)中得到了廣泛的應(ying)(ying)用(yong)(yong)。

2. 壓電(dian)晶體

在機械(xie)力(li)的(de)(de)作用(yong)下,產(chan)生形(xing)變,使(shi)帶電(dian)粒子具有相對(dui)位移(yi),使(shi)晶(jing)(jing)(jing)(jing)體(ti)(ti)表面具有正負束縛電(dian)荷(he),這樣的(de)(de)晶(jing)(jing)(jing)(jing)體(ti)(ti)叫作壓電(dian)晶(jing)(jing)(jing)(jing)體(ti)(ti)。壓電(dian)晶(jing)(jing)(jing)(jing)體(ti)(ti)極軸兩端產(chan)生的(de)(de)電(dian)勢(shi)差的(de)(de)性質(zhi)稱為壓電(dian)特性。分為單(dan)(dan)晶(jing)(jing)(jing)(jing)體(ti)(ti)與(yu)多(duo)(duo)(duo)(duo)晶(jing)(jing)(jing)(jing)體(ti)(ti),其中多(duo)(duo)(duo)(duo)晶(jing)(jing)(jing)(jing)體(ti)(ti)材(cai)料(liao)又(you)稱作壓電(dian)陶瓷。硫(liu)酸鋰(li)、鈮酸鋰(li)、石英(ying)等為常用(yong)的(de)(de)單(dan)(dan)晶(jing)(jing)(jing)(jing)材(cai)料(liao)。常用(yong)的(de)(de)多(duo)(duo)(duo)(duo)晶(jing)(jing)(jing)(jing)材(cai)料(liao)有鈦酸鋇、鈦酸鉛等。多(duo)(duo)(duo)(duo)晶(jing)(jing)(jing)(jing)體(ti)(ti)材(cai)料(liao)又(you)稱為壓電(dian)陶瓷。其中單(dan)(dan)晶(jing)(jing)(jing)(jing)體(ti)(ti)材(cai)料(liao)對(dui)接收更靈敏,多(duo)(duo)(duo)(duo)晶(jing)(jing)(jing)(jing)材(cai)料(liao)的(de)(de)發射靈敏度較高(gao)。

超(chao)聲(sheng)(sheng)波(bo)換能器(qi)中(zhong)的(de)(de)(de)(de)壓(ya)電(dian)(dian)(dian)晶(jing)片(pian)具有(you)壓(ya)電(dian)(dian)(dian)效(xiao)應,可(ke)利用超(chao)聲(sheng)(sheng)換能器(qi)中(zhong)壓(ya)電(dian)(dian)(dian)芯片(pian)的(de)(de)(de)(de)壓(ya)電(dian)(dian)(dian)效(xiao)應實現超(chao)聲(sheng)(sheng)波(bo)的(de)(de)(de)(de)產生(sheng)和接收。在(zai)壓(ya)電(dian)(dian)(dian)晶(jing)體(ti)兩側的(de)(de)(de)(de)電(dian)(dian)(dian)極通交流電(dian)(dian)(dian),通過(guo)逆壓(ya)電(dian)(dian)(dian)效(xiao)應可(ke)知(zhi),晶(jing)片(pian)會(hui)在(zai)厚度(du)方向產生(sheng)伸(shen)縮的(de)(de)(de)(de)機(ji)(ji)械(xie)(xie)振動,將(jiang)電(dian)(dian)(dian)能轉換成(cheng)聲(sheng)(sheng)能(機(ji)(ji)械(xie)(xie)能),此時(shi)探頭便(bian)發射出超(chao)聲(sheng)(sheng)波(bo),再通過(guo)合適(shi)的(de)(de)(de)(de)耦合劑(ji)與待檢測工件(jian)連接,振動產生(sheng)的(de)(de)(de)(de)超(chao)聲(sheng)(sheng)波(bo)便(bian)進(jin)入了工件(jian)。當壓(ya)電(dian)(dian)(dian)晶(jing)片(pian)接收到(dao)超(chao)聲(sheng)(sheng)波(bo)時(shi),受到(dao)聲(sheng)(sheng)波(bo)能量的(de)(de)(de)(de)激發便(bian)會(hui)產生(sheng)振動發生(sheng)機(ji)(ji)械(xie)(xie)形變從(cong)而使晶(jing)體(ti)兩個表面產生(sheng)大小相(xiang)同極性相(xiang)反(fan)的(de)(de)(de)(de)電(dian)(dian)(dian)荷(he),形成(cheng)超(chao)聲(sheng)(sheng)波(bo)頻率的(de)(de)(de)(de)高頻電(dian)(dian)(dian)壓(ya),超(chao)聲(sheng)(sheng)波(bo)探傷儀的(de)(de)(de)(de)接收電(dian)(dian)(dian)路正是(shi)通過(guo)對返回的(de)(de)(de)(de)電(dian)(dian)(dian)信號(hao)進(jin)行一系列(lie)處(chu)理從(cong)而判斷(duan)工件(jian)是(shi)否(fou)有(you)傷。顯然,超(chao)聲(sheng)(sheng)波(bo)換能器(qi)的(de)(de)(de)(de)作用是(shi)實現聲(sheng)(sheng)能與電(dian)(dian)(dian)能的(de)(de)(de)(de)相(xiang)互轉換。

壓電(dian)晶體分為(wei)單壓電(dian)晶體與(yu)多晶壓電(dian)陶瓷。其中,壓電(dian)陶瓷占有相當大的(de)比重,是市場上應(ying)用最(zui)為(wei)廣泛的(de)壓電(dian)材料。分述如下:

a. 壓(ya)電(dian)單晶體: 石英、水溶性(xing)壓(ya)電(dian)晶體(酒石酸(suan)鉀鈉、酒石酸(suan)乙烯二(er)銨(an)、酒石酸(suan)二(er)鉀、硫酸(suan)鉀等)。

b. 多晶(jing)體壓(ya)電(dian)陶瓷(ci): 鈦酸鋇(bei)壓(ya)電(dian)陶瓷(ci)、鋯鈦酸鉛系壓(ya)電(dian)陶瓷(ci)、鈮(ni)酸鹽系壓(ya)電(dian)陶瓷(ci)和鈮(ni)鎂酸鉛壓(ya)電(dian)陶為代(dai)表性的(de)壓(ya)電(dian)陶瓷(ci)。

3. 壓電單晶體

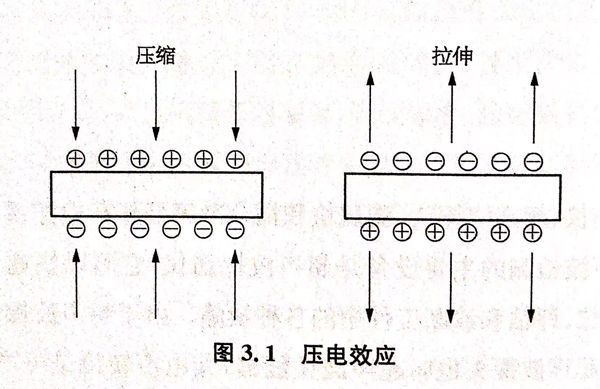

石英(ying)晶體性能(neng)穩(wen)定(ding),機(ji)械(xie)強度高,絕緣性能(neng)好(hao),但價格昂貴(gui),壓(ya)電系數遠低于壓(ya)電陶瓷(ci),所以一般僅用于標準(zhun)儀器(qi)或要(yao)求較高的傳(chuan)感器(qi)。石英(ying)晶體諧振器(qi)具有很高的品質因數和穩(wen)定(ding)性,可用于對講機(ji)、電子手表、電視(shi)機(ji)、電子儀器(qi)等(deng)產品的諧振腔,如圖3.2所示為石英(ying)晶體的壓(ya)電模型。

此外,酒石(shi)酸鉀(jia)鈉、酒石(shi)酸乙烯二(er)銨、酒石(shi)酸二(er)鉀(jia)、硫酸鉀(jia)等(deng)水溶(rong)性壓(ya)電(dian)(dian)晶(jing)(jing)體是常見(jian)的(de)(de)單晶(jing)(jing)壓(ya)電(dian)(dian)材料(liao)。目前(qian),通過單晶(jing)(jing)化來提高多晶(jing)(jing)壓(ya)電(dian)(dian)陶(tao)瓷(如鈦酸鉛)的(de)(de)壓(ya)電(dian)(dian)性能是壓(ya)電(dian)(dian)材料(liao)的(de)(de)研究熱點之一。

4. 多晶體(ti)壓電陶瓷

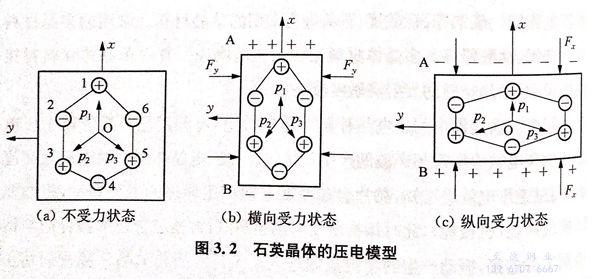

多(duo)晶體壓(ya)(ya)(ya)電(dian)(dian)陶瓷(ci)是一種具有壓(ya)(ya)(ya)電(dian)(dian)效(xiao)應的功(gong)能陶瓷(ci)材(cai)料,在高(gao)溫(wen)下將氧化物混合燒(shao)結,可以實現機械能和電(dian)(dian)能的轉(zhuan)換。目前(qian)市場上(shang)常見的多(duo)晶體壓(ya)(ya)(ya)電(dian)(dian)陶瓷(ci)為鋯鈦酸鉛(qian)(qian)(PZT)系(xi)壓(ya)(ya)(ya)電(dian)(dian)材(cai)料。壓(ya)(ya)(ya)電(dian)(dian)材(cai)料的研究熱點主要有:①. 低溫(wen)燒(shao)結PZT陶瓷(ci);②. 大功(gong)率高(gao)轉(zhuan)換效(xiao)率的PZT壓(ya)(ya)(ya)電(dian)(dian)陶瓷(ci);③. 壓(ya)(ya)(ya)電(dian)(dian)復合材(cai)料;④. 無鉛(qian)(qian)壓(ya)(ya)(ya)電(dian)(dian)陶瓷(ci);⑤. 單晶化。如圖3.3所(suo)示為壓(ya)(ya)(ya)電(dian)(dian)陶瓷(ci)的發展歷史。

5. 壓電(dian)晶體的(de)主要性能參數

a. 壓電應變常數 d33

壓電(dian)應變常數表示單位(wei)電(dian)壓作用于(yu)壓電(dian)晶(jing)體(ti)時(shi)所產生的(de)應變大小,其表達(da)式為(wei)

d33 = Δt/U

式中 Δt-晶片在(zai)厚度方向的(de)形(xing)變(bian)量,單位為(wei)m(米(mi));

U--施加在壓電晶片(pian)兩面的應(ying)力,單位為(wei)V(伏特(te))。

壓電應變常數d33是測量壓電晶體材料發射靈敏度的重要參數。d33值越大,發射性能越差,發射靈敏度越高。

b. 壓電電壓常數 g33

壓電(dian)電(dian)壓常數(shu)表示施加在壓電(dian)晶片(pian)上的(de)單位應(ying)力所產(chan)生的(de)壓電(dian)梯度大小(xiao),其(qi)表達式(shi)為

g33 = Up/P

式中 P-施加在壓電晶片兩面的應力,單(dan)位為N(牛);

Up-晶片表面產生的電壓梯度,Up = U/t,單位為V/m(伏特/米)。

c. 介電常(chang)數 ε

介電常數是表示絕緣能力特性(xing)的一個(ge)系(xi)數,其(qi)表達式為

ε=C t/A

式中 C-電容(rong)器電容(rong);

t-電容器極板距(ju)離;

A-電容器極板面積。

由介電(dian)(dian)(dian)常數表達式可知,當電(dian)(dian)(dian)容器極板距(ju)離和(he)面積一(yi)(yi)定時,介電(dian)(dian)(dian)常數ε越大,電(dian)(dian)(dian)容C越大,即電(dian)(dian)(dian)容器存(cun)儲(chu)電(dian)(dian)(dian)量越多。壓電(dian)(dian)(dian)晶體(ti)的(de)(de)ε應根據(ju)不同的(de)(de)用途來選取。超聲波(bo)檢(jian)測(ce)的(de)(de)壓電(dian)(dian)(dian)晶體(ti),頻率(lv)要求(qiu)高(gao)時,應小一(yi)(yi)些(xie)。由于ε小、C小,電(dian)(dian)(dian)容器充(chong)放電(dian)(dian)(dian)時間(jian)短,頻率(lv)高(gao)。反(fan)之,應該大一(yi)(yi)些(xie)。

d. 機電耦(ou)合系數 K

機(ji)電(dian)耦合系數K,表示壓電(dian)材料機(ji)械(xie)能(聲能)與(yu)電(dian)能的轉換(huan)效率(lv),即

K= 轉換的能量/輸入的能量

對于正壓(ya)電(dian)(dian)效應(ying),K=轉(zhuan)換(huan)(huan)的電(dian)(dian)能/輸入的機械(xie)(xie)能。對于負壓(ya)電(dian)(dian)效應(ying),K=轉(zhuan)換(huan)(huan)的機械(xie)(xie)能/輸入的電(dian)(dian)能。

探頭晶片振動時,會產生厚度和徑向兩個方向的伸縮變形,因此機電耦合系數分為厚度方向Kt和徑向Kp。Kt大,探測靈敏度高;Kp大,低頻諧振波增多,發射脈沖變寬,導致分辨力降低,盲區增大。

e. 機械品質因子 θm

壓(ya)電(dian)晶(jing)片在諧振時儲存(cun)的機械(xie)能E與一個周(zhou)期內損(sun)耗的能量E損(sun)之比(bi)稱為機械(xie)品質因子θm.

壓電晶片振動損耗的能量主要是內摩擦引起的。θm值對分辨率有較大的影響:θm值越大,表示損耗越小,晶片持續震動時間長,脈沖寬度大,分辨率低。反之,θm值越小,表示損耗越大,脈沖寬度小,分辨率就高。

f. 頻率常數Ni

由駐波理論可知,壓電(dian)晶片在高頻(pin)電(dian)脈(mo)沖激勵下產生共(gong)振的條件是

這意味著壓電晶片厚度與固有頻率的乘積是一個常數,稱為頻率常數,用Ni表示。厚度一定,頻率常數大的晶片材料,其固有頻率高。晶片材料一定,頻率越高,厚度越小。

g. 居里溫度Tc

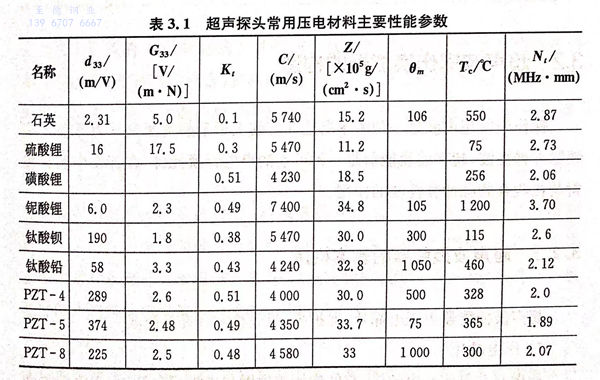

與磁性材料一樣,壓電材料的壓電效應與溫度有關。它只能在一定的溫度范圍內產生,超過這個溫度范圍,壓電效應就消失了。壓電材料的壓電效應消失的溫度稱為壓電材料的居里溫度,用Tc表示。例如,石英Tc=570℃,鐵酸鋇Tc=115℃.常見壓電材料性能參數見表3.1。

6. 壓電晶體的選用原則(ze)

對于壓(ya)電(dian)超聲換能器采用(yong)的壓(ya)電(dian)晶片(pian),其(qi)選用(yong)原則可(ke)參考(kao)如下:

a. 性(xing)能(neng)指(zhi)(zhi)標適當,以滿足(zu)具體使用要求為度(du)量(liang),不宜過分追求各項性(xing)能(neng)的高指(zhi)(zhi)標;

b. 工作性能要穩定、可靠(kao);

c. 價格(ge)低廉,加工方(fang)便。

超聲(sheng)波換(huan)能(neng)器對晶片的要(yao)求如下(xia):

a. 機電耦合系(xi)數K較大,以(yi)便獲(huo)得較高的轉(zhuan)換效(xiao)率;

b. 機械品質因子θm較大,以便獲得較高的轉換效率;

c. 壓電應變常數d33和壓電電壓常數g33較大,以便獲得較高的發射和接收靈敏度;

d. 頻率常數Ni較大,介電常數ε較小,以便獲得較高的頻率;

f. 居里溫度Tc較高,聲阻抗 Z 適當。