在高壓管道檢修中,需更換的管段基本上都屬于封閉管段,在新裝設的管線中,亦必定含有封閉管段。近年來世界上一些國家推行預制管系施工法,即把一些管段和管件事先加工預裝好,在現場只是進行最后組裝和焊接,使安裝速度大大加快。這就要求必須精確、細致地進行現場測量,繪制出符合現場實際情況的施工單線圖,這樣才能保證預制的準確和現場安裝順利進行。

現場測(ce)(ce)量的(de)常用方法是掛線測(ce)(ce)量法,如能(neng)用經緯儀幫(bang)助測(ce)(ce)量,則效果會(hui)更好。現場測(ce)(ce)量的(de)常用工具比較(jiao)簡(jian)單(dan),一般(ban)常用的(de)有:

水平尺(chi)--用以(yi)檢查掛線的(de)水平度(du)(du)(du)或坡度(du)(du)(du)、管口法蘭平面(mian)的(de)水平度(du)(du)(du)或垂直度(du)(du)(du);

彎尺(直角尺)-用以測量和(he)檢查兩根互(hu)相垂直的掛線;

丁字(zi)尺-用以(yi)(yi)檢查(cha)掛線(xian)是否為(wei)所(suo)測管子的中心線(xian),也(ye)可用以(yi)(yi)檢查(cha)平行線(xian)和垂(chui)線(xian);

量角規(gui)-用以檢(jian)查掛線的(de)交角;

鋼尺-用以測量直(zhi)線長度;

線墜-吊線用;

粉線-掛線用。

1. 幾種典(dian)型管段的現場測量

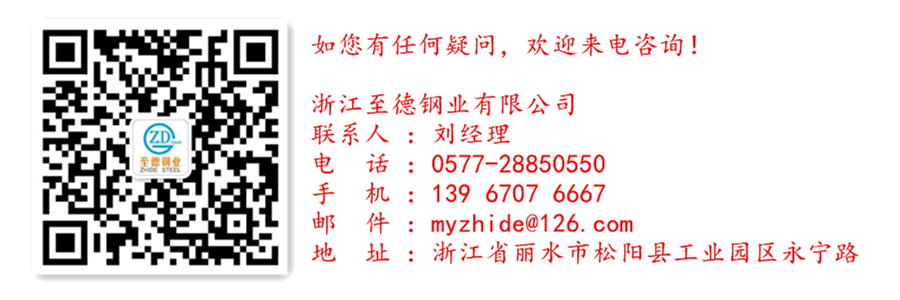

①. 90°彎(wan)管

a. 水(shui)平90°彎(wan)管

如圖3-45所示,首(shou)先檢查(cha)已有的(de)法蘭接管(guan)(guan)口垂(chui)直度(用(yong)水平尺(chi)(chi)或吊線墜的(de)方法),在管(guan)(guan)口中心(xin)掛兩條(tiao)粉線(線Ⅰ和線Ⅱ),用(yong)直角尺(chi)(chi)檢查(cha)并調整(zheng)粉線Ⅰ、Ⅱ,使之成90°,兩線的(de)交(jiao)點(dian)便是(shi)測量的(de)標點(dian)。用(yong)鋼尺(chi)(chi)量出L1、L2的(de)尺(chi)(chi)寸(cun)。

b. 垂直90°彎(wan)管

如圖3-46所(suo)示,用水平尺或(huo)吊(diao)線(xian)(xian)(xian)墜的(de)方(fang)法檢查(cha)水平管段法蘭(lan)接管口(kou)的(de)垂直度,從該管口(kou)中心掛水平粉(fen)線(xian)(xian)(xian)Ⅰ;檢查(cha)垂直管段法蘭(lan)接管口(kou)的(de)水平度,從該管口(kou)中心吊(diao)線(xian)(xian)(xian)墜。用直角尺檢查(cha)并調整線(xian)(xian)(xian)Ⅰ、Ⅱ,使之成90°,兩線(xian)(xian)(xian)的(de)交(jiao)點便(bian)是測量的(de)標點。用鋼尺量出L1、L2的(de)尺寸。

c. 水(shui)平90°來回彎管

這(zhe)類(lei)彎(wan)(wan)管段相當于(yu)兩(liang)個90°彎(wan)(wan)管的組(zu)合體,測量(liang)和預制均要(yao)求很準確。測量(liang)時(shi),一般(ban)只掛兩(liang)根粉線即可,掛線及測量(liang)方法參見(jian)圖3-47。

②. 180°彎(wan)管

這類彎管(guan)(guan)管(guan)(guan)段也稱(cheng)為U形管(guan)(guan)段,相(xiang)當(dang)于兩(liang)(liang)個90°彎管(guan)(guan)的(de)組合(he)體(ti),測(ce)量(liang)和預(yu)制均要求很準(zhun)確。如圖3-48所示(shi),測(ce)量(liang)時,一般只掛(gua)兩(liang)(liang)根(gen)粉線Ⅰ、Ⅱ,量(liang)出L1、L2的(de)尺(chi)(chi)寸(cun)(cun);L3的(de)尺(chi)(chi)寸(cun)(cun)可(ke)以不(bu)測(ce),根(gen)據預(yu)制、加工要求的(de)最(zui)小尺(chi)(chi)寸(cun)(cun)(最(zui)小直段長度和彎制半徑)確定(ding)(ding),在確定(ding)(ding)L3的(de)尺(chi)(chi)寸(cun)(cun)時,應考慮(lv)使(shi)這個管(guan)(guan)段的(de)展開長度盡量(liang)小些。若現場有障礙物(wu),則L3的(de)尺(chi)(chi)寸(cun)(cun)應按現場實際(ji)情況進行測(ce)量(liang)和確定(ding)(ding)。

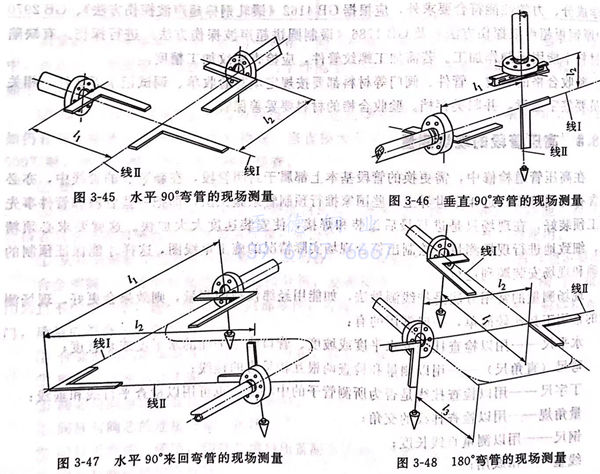

③. 固定角彎(wan)管

由于(yu)現(xian)場已有(you)的(de)接(jie)管(guan)(guan)(guan)口(kou)是固定(ding)的(de),因此固定(ding)角彎管(guan)(guan)(guan)段的(de)彎曲(qu)角、彎曲(qu)位置由已有(you)的(de)接(jie)管(guan)(guan)(guan)所決(jue)定(ding)。這類彎管(guan)(guan)(guan)段的(de)測量(liang)和預制、加工均要求(qiu)很準確。如圖3-49所示,可采用掛(gua)三條粉線(xian)的(de)方法進行測量(liang),線(xian)Ⅰ、Ⅱ為(wei)基本線(xian),線(xian)皿為(wei)輔(fu)助線(xian),通過管(guan)(guan)(guan)口(kou)中心與線(xian)I垂(chui)直。將掛(gua)線(xian)調(diao)整(zheng)好(hao)后,量(liang)出彎管(guan)(guan)(guan)段的(de)折線(xian)尺寸L1、L2,同時測量(liang)L1、L2和彎曲(qu)角a。由于(yu)這幾個(ge)數值可按直角三角形的(de)邊角關系進行計算,因此可用于(yu)相互(hu)驗(yan)證、核對(dui)。

④. 任意(yi)角彎管

任意(yi)角彎管(guan)測(ce)(ce)量(liang)時,其中一個接(jie)管(guan)口是固定的(de),另一個接(jie)管(guan)口可(ke)旋轉(如與三通、彎頭等管(guan)件(jian)連接(jie)),如圖3-50所示(shi)。在這種情況下(xia),彎曲角α可(ke)任意(yi)選(xuan)定,為了測(ce)(ce)量(liang)、預制方便,最(zui)好(hao)將a選(xuan)為30°、45°或60°。測(ce)(ce)量(liang)時,掛(gua)三條粉線(xian)(xian)(xian)(xian),線(xian)(xian)(xian)(xian)Ⅰ、線(xian)(xian)(xian)(xian)Ⅱ為基本線(xian)(xian)(xian)(xian);線(xian)(xian)(xian)(xian)皿(min)為輔助線(xian)(xian)(xian)(xian),通過該管(guan)口中心與線(xian)(xian)(xian)(xian)Ⅰ垂直。將掛(gua)線(xian)(xian)(xian)(xian)調整好(hao)后,量(liang)出彎管(guan)

段的折線(xian)(xian)尺寸(cun)(cun)L1、L2,同時(shi)(shi)測量L1、L2和(he)彎曲角(jiao)α.在將現場測得的a換算為選(xuan)定(ding)的彎曲角(jiao)(30°、45°或(huo)60°)時(shi)(shi),折線(xian)(xian)L1、L2的尺寸(cun)(cun)和(he)L1、L2的尺寸(cun)(cun)會相(xiang)應變化(hua),此時(shi)(shi),必須考(kao)慮旋轉中心(xin)距(ju)H的尺寸(cun)(cun)。最后,用放大樣或(huo)計算的方法確定(ding)施(shi)工單線(xian)(xian)圖上(shang)的尺寸(cun)(cun)L1、L2、L1、L2和(he)彎曲角(jiao)α。

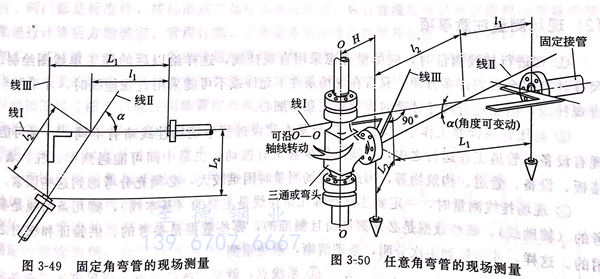

⑤. 任意角來回(hui)彎(wan)管

這類管段用(yong)以連接兩條平行的(de)管線(xian)(xian)(xian),管段由(you)三段折線(xian)(xian)(xian)組成,由(you)于(yu)折線(xian)(xian)(xian)的(de)夾角(jiao)可由(you)施工(gong)人任意(yi)(yi)選(xuan)定,故稱(cheng)為(wei)任意(yi)(yi)角(jiao)來回彎(wan)(wan)管。通常,因管段的(de)兩個(ge)彎(wan)(wan)曲角(jiao)a(即(ji)折線(xian)(xian)(xian)夾角(jiao))總是相等的(de)(且α小(xiao)于(yu)90°),故又稱(cheng)為(wei)同位角(jiao)彎(wan)(wan)管或(huo)等差彎(wan)(wan)管。如圖(tu)3-51所示,測量(liang)時,掛兩條粉(fen)線(xian)(xian)(xian)(線(xian)(xian)(xian)Ⅰ和(he)線(xian)(xian)(xian)Ⅱ),只測量(liang)L1、L2的(de)尺寸即(ji)可。折線(xian)(xian)(xian)尺寸L1、L2可在(zai)繪制施工(gong)單線(xian)(xian)(xian)圖(tu)時,任意(yi)(yi)選(xuan)擇一個(ge)比L1/2小(xiao)的(de)尺寸(彎(wan)(wan)曲角(jiao)α必然小(xiao)于(yu)90°)。

如現(xian)場(chang)有障礙物,L1、L2的尺寸(cun)不(bu)能任意確定,必須在現(xian)場(chang)測出(chu)具體(ti)數字。

⑥. 搖頭彎(wan)管

若現場已(yi)有的(de)兩固定(ding)接管(guan)口中心軸線(xian)呈異面直(zhi)線(xian),則必須采用(yong)擺(bai)頭(tou)(tou)彎(wan)管(guan)連(lian)接,現場測量時(shi),須測出擺(bai)頭(tou)(tou)彎(wan)管(guan)的(de)空間尺寸L1、L2、L3。由(you)于將高壓(ya)管(guan)子(zi)預(yu)制成規定(ding)尺寸和(he)形狀的(de)擺(bai)頭(tou)(tou)彎(wan)管(guan)十分不(bu)易(yi),所以(yi)實際施工時(shi),都在豎直(zhi)管(guan)段上加一對法蘭,使擺(bai)頭(tou)(tou)彎(wan)管(guan)變成兩個90°的(de)彎(wan)管(guan)管(guan)段。擺(bai)頭(tou)(tou)彎(wan)管(guan)的(de)現場掛線(xian)和(he)測量情(qing)況(kuang)如圖3-52所示。

上面介紹的(de)幾(ji)種典型管段的(de)現(xian)場(chang)測量是實(shi)際(ji)施(shi)工中(zhong)常見的(de)、常采用的(de)方法,但現(xian)場(chang)測量的(de)范疇(chou)和方法遠不止(zhi)這(zhe)些,掌(zhang)握了(le)這(zhe)幾(ji)種基(ji)本(ben)方法后,可根據現(xian)場(chang)實(shi)際(ji)情況組合運(yun)用,舉一反(fan)三,更(geng)(geng)巧、更(geng)(geng)簡捷、更(geng)(geng)準(zhun)確地測量現(xian)場(chang)有關數據,以準(zhun)確地確定和繪制高(gao)壓管段施(shi)工單線圖(tu)。

2. 現場測量注意事(shi)項

①. 在(zai)進行(xing)掛(gua)(gua)線測量時(shi),應(ying)盡(jin)量考慮采(cai)用直觀(guan)(guan)掛(gua)(gua)線,這樣給以后(hou)的(de)施工單線圖繪制(zhi)、尺(chi)寸(cun)計算都會帶(dai)來許多(duo)方便。只(zhi)有在(zai)現場條件不(bu)允許或不(bu)可(ke)能采(cai)用直觀(guan)(guan)掛(gua)(gua)線時(shi),才采(cai)用非直觀(guan)(guan)掛(gua)(gua)線,但在(zai)進行(xing)尺(chi)寸(cun)計算時(shi)應(ying)特別注(zhu)意和(he)細(xi)心。

②. 高壓管(guan)道檢修工作中的現場掛(gua)線(xian)(xian)與基(ji)本(ben)建設過程中現場掛(gua)線(xian)(xian)略(lve)有不同,一是可能現有設備、管(guan)道正(zheng)在運行之中,系線(xian)(xian)點較(jiao)少(shao)甚至有振動,二(er)是中間可能遇(yu)到(dao)梁、柱、墻(qiang)、樓板、設備、管(guan)道、構筑物等,因(yin)此在現場測量時困難(nan)較(jiao)大(da),必(bi)須充分考慮到(dao)這些(xie)因(yin)素(su)。

③. 現場掛線(xian)測(ce)量時(shi),一定要注意到哪(na)幾條粉(fen)線(xian)是主(zhu)要的(de)(基本線(xian)),哪(na)幾條粉(fen)線(xian)是參(can)考的(de)(輔助線(xian)),哪(na)些(xie)數(shu)據是必須測(ce)量而(er)且測(ce)準的(de),哪(na)些(xie)數(shu)據是參(can)考的(de)、供驗證和核對之用的(de)。這樣(yang),才能做到主(zhu)次分(fen)明,條理清晰,避免重測(ce)。

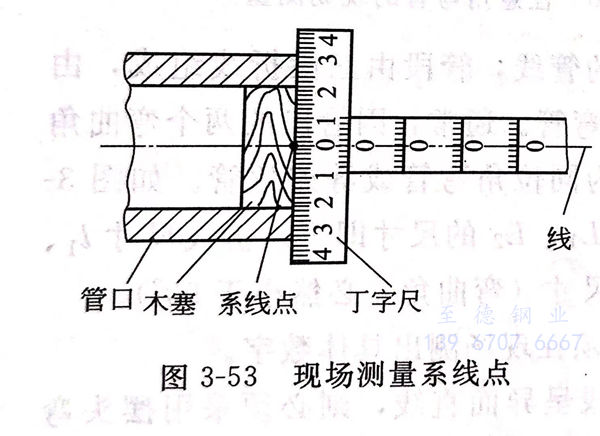

④. 系(xi)(xi)線(xian)點(dian)(dian),就是(shi)掛線(xian)的端點(dian)(dian)。應盡可(ke)(ke)能(neng)(neng)用(yong)設(she)備和管子的管口中(zhong)心作(zuo)為系(xi)(xi)線(xian)點(dian)(dian),如圖(tu)3-53所示。采用(yong)其他(ta)物(wu)體作(zuo)為系(xi)(xi)線(xian)點(dian)(dian)時(shi),必須(xu)考慮其牢固(gu)程(cheng)度和可(ke)(ke)能(neng)(neng)在將(jiang)來發生變動等(deng)情況。

⑤. 現場掛(gua)(gua)線(xian)(xian),除利(li)用線(xian)(xian)墜(zhui)的(de)(de)(de)粉線(xian)(xian)之(zhi)外(wai),必定有兩個(ge)系線(xian)(xian)點(dian),其中(zhong)一個(ge)是(shi)固(gu)定的(de)(de)(de),另一個(ge)是(shi)可(ke)(ke)調的(de)(de)(de),固(gu)定的(de)(de)(de)系線(xian)(xian)點(dian)應盡(jin)可(ke)(ke)能(neng)地采用管口中(zhong)心。因為現場掛(gua)(gua)線(xian)(xian)測量(liang)往(wang)往(wang)很難(nan)做到(dao)一次(ci)成功,需經(jing)幾次(ci)調整后才能(neng)進行測量(liang),可(ke)(ke)調的(de)(de)(de)系線(xian)(xian)點(dian)就(jiu)是(shi)為此而設置的(de)(de)(de)。

掛(gua)線(xian)時,兩系線(xian)點的距離不(bu)宜很遠,否則(ze)將(jiang)因粉(fen)線(xian)自身(shen)重量產生較大的撓度(du)而影(ying)響測量結果(guo)。在吊掛互相交叉的(de)(de)三條粉線(xian)(xian)時,其(qi)中兩條粉線(xian)(xian)只能(neng)在另一條線(xian)(xian)的(de)(de)同側,否則(ze)會(hui)造(zao)成測量結果不真實。粉線(xian)(xian)的(de)(de)交叉點應涂色或(huo)用其(qi)他方(fang)法(fa)做(zuo)上標志,避免粉線(xian)(xian)因沖碰、振動等(deng)緣故(gu)變位后重新(xin)找標點、重新(xin)測量。

⑥. 吊掛垂線時,其下(xia)端為線墜(zhui),只有在線墜(zhui)不(bu)擺(bai)動(dong)時方可(ke)進(jin)行測量(liang)。在現場,由(you)于振動(dong)、微風等(deng)影響,線墜(zhui)可(ke)能久擺(bai)不(bu)息,此(ci)時,可(ke)在線墜(zhui)下(xia)置一盛有機(ji)油(you)的油(you)盆,使線墜(zhui)的尖端浸(jin)在油(you)中,線墜(zhui)便能很快(kuai)地穩定(ding)下(xia)來。

⑦. 兩條粉線在空間(jian)垂直(zhi)相(xiang)交時(shi),一定要用(yong)直(zhi)角尺(chi)檢查(cha)后方可測量(liang)其他有(you)關尺(chi)寸。

⑧. 現場(chang)測量時,應考慮用哪一管(guan)段(duan)作為最后安(an)裝(zhuang)的(de)管(guan)段(duan)-封閉(bi)管(guan)段(duan)。封閉(bi)管(guan)段(duan)應便于安(an)裝(zhuang)、測準、加工,如果在管(guan)線安(an)裝(zhuang)時發現新的(de)問(wen)題,封閉(bi)管(guan)段(duan)還可以(yi)起到(dao)彌(mi)補作用。

3. 制(zhi)加工尺寸的確定(ding)

為了高(gao)壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)預(yu)制(zhi)(zhi)的(de)(de)需要(yao)(yao)和進一步指導高(gao)壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)道的(de)(de)安(an)裝,在(zai)現(xian)場(chang)測量(liang)之后,必須根據測量(liang)結果繪制(zhi)(zhi)高(gao)壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)線(xian)(xian)(xian)(xian)施工(gong)(gong)(gong)(gong)單(dan)線(xian)(xian)(xian)(xian)圖(tu)(tu)和高(gao)壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)的(de)(de)預(yu)制(zhi)(zhi)加(jia)工(gong)(gong)(gong)(gong)尺(chi)(chi)(chi)寸(cun)(cun)(cun)圖(tu)(tu)。高(gao)壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)線(xian)(xian)(xian)(xian)施工(gong)(gong)(gong)(gong)單(dan)線(xian)(xian)(xian)(xian)圖(tu)(tu),是從(cong)該管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)線(xian)(xian)(xian)(xian)的(de)(de)連接(jie)起(qi)點到終點,包(bao)括管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)、管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)件(jian)(jian)、閥門(men)的(de)(de)系統圖(tu)(tu),在(zai)單(dan)線(xian)(xian)(xian)(xian)圖(tu)(tu)上(shang)應注(zhu)明管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)、管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)件(jian)(jian)和閥門(men)的(de)(de)編號、規格(ge)、尺(chi)(chi)(chi)寸(cun)(cun)(cun)、材料(liao)、介質流向、標高(gao)以(yi)及主要(yao)(yao)障礙物的(de)(de)位置(zhi)和大小(xiao)等(deng),在(zai)某(mou)些(xie)場(chang)合,還要(yao)(yao)注(zhu)明與其(qi)他設備、管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)道、構筑物的(de)(de)間隔尺(chi)(chi)(chi)寸(cun)(cun)(cun)。在(zai)單(dan)線(xian)(xian)(xian)(xian)圖(tu)(tu)中(zhong),管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)件(jian)(jian)、閥門(men)都是標準件(jian)(jian),按標準或產(chan)品樣本查(cha)得即(ji)可(ke),只(zhi)有管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)尺(chi)(chi)(chi)寸(cun)(cun)(cun)必須根據現(xian)場(chang)測量(liang)的(de)(de)結果進行計(ji)算(suan)(suan)后方能(neng)確定。管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)計(ji)算(suan)(suan),主要(yao)(yao)是算(suan)(suan)出該管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)的(de)(de)展開長(chang)度(du)(du),以(yi)便據以(yi)下料(liao)和彎(wan)(wan)曲加(jia)工(gong)(gong)(gong)(gong),其(qi)計(ji)算(suan)(suan)方法(fa)與中(zhong)、低壓(ya)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)道的(de)(de)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)計(ji)算(suan)(suan)方法(fa)基本相同,但須考慮閥門(men)和管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)件(jian)(jian)尺(chi)(chi)(chi)寸(cun)(cun)(cun)、透鏡墊厚度(du)(du)的(de)(de)影(ying)響,而(er)且要(yao)(yao)求(qiu)計(ji)算(suan)(suan)的(de)(de)準確度(du)(du)更高(gao),管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)尺(chi)(chi)(chi)寸(cun)(cun)(cun)計(ji)算(suan)(suan)本身并不復(fu)雜。在(zai)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)的(de)(de)預(yu)制(zhi)(zhi)加(jia)工(gong)(gong)(gong)(gong)尺(chi)(chi)(chi)寸(cun)(cun)(cun)圖(tu)(tu)上(shang),應注(zhu)明該管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)段(duan)(duan)(duan)的(de)(de)展開長(chang)度(du)(du)、彎(wan)(wan)曲半徑、起(qi)彎(wan)(wan)點和終彎(wan)(wan)點位置(zhi)、直(zhi)管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)部分(fen)長(chang)度(du)(du)、機加(jia)工(gong)(gong)(gong)(gong)部分(fen)的(de)(de)尺(chi)(chi)(chi)寸(cun)(cun)(cun)(管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)端(duan)螺(luo)紋、管(guan)(guan)(guan)(guan)(guan)(guan)(guan)(guan)端(duan)密封面(mian))以(yi)及其(qi)他加(jia)工(gong)(gong)(gong)(gong)要(yao)(yao)求(qiu)。

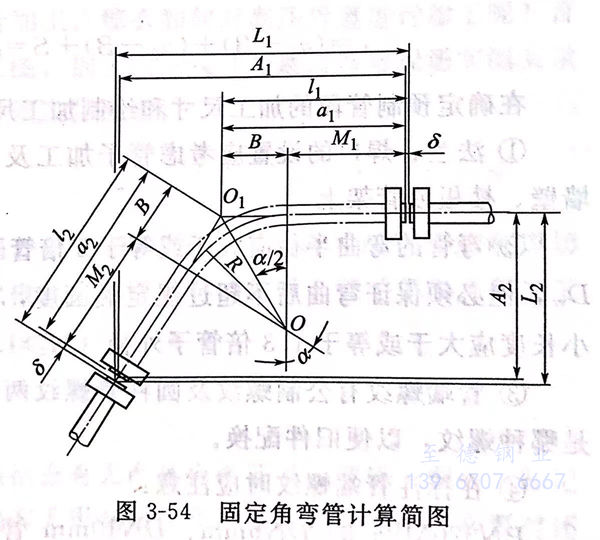

現(xian)場測得的(de)數據不是(shi)施工(gong)尺寸,更不是(shi)加工(gong)、下料的(de)尺寸,必須經過計算,方能繪制出管(guan)段(duan)的(de)預制加工(gong)尺寸圖(tu)(tu)。下面以固定角彎管(guan)為例,介紹現(xian)場測量后管(guan)段(duan)展開(kai)長度的(de)計算(參見圖(tu)(tu)3-54)。

已知(zhi):現場測量的數據(ju)(ju)(ju)L1、L2、L1、L2及a,根(gen)據(ju)(ju)(ju)《高(gao)(gao)壓(ya)(ya)管(guan)、管(guan)件及緊固件通(tong)用(yong)設計》確(que)定(ding)或(huo)(huo)選用(yong)的數據(ju)(ju)(ju)R、8或(huo)(huo)Δ,在計算(suan)時需根(gen)據(ju)(ju)(ju)《高(gao)(gao)壓(ya)(ya)管(guan)、管(guan)件及緊固件通(tong)用(yong)設計》核對的數據(ju)(ju)(ju)M1、M2。計算(suan)固定(ding)角為α的高(gao)(gao)壓(ya)(ya)彎(wan)管(guan)管(guan)段展(zhan)開長度c。

在確定預制(zhi)管段的加(jia)工尺寸和繪制(zhi)加(jia)工尺寸圖時須注意以下幾點(dian):

①. 法蘭(lan)、焊口的設置(zhi)應考慮管子加工及管段的安裝、維護、檢修的方便,不得置(zhi)于墻(qiang)壁、樓(lou)板(ban)或管架上。

②. 彎(wan)(wan)(wan)管(guan)的彎(wan)(wan)(wan)曲半徑應大(da)于(yu)或(huo)等(deng)于(yu)5倍管(guan)子外徑,即R≥5Dw.特(te)殊情況下亦允許R<Dw,但必須保證彎(wan)(wan)(wan)曲后不超過規定橢圓度(du),壁厚在安全范圍內。彎(wan)(wan)(wan)管(guan)的管(guan)端直管(guan)部分最(zui)小長(chang)度(du)應大(da)于(yu)或(huo)等(deng)于(yu)1.3倍管(guan)子外徑(M≥1.3Dw),且(qie)不得(de)小于(yu)60mm。

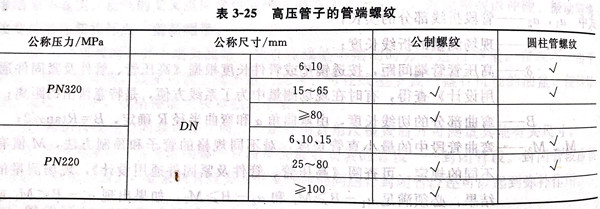

③. 管端螺(luo)(luo)紋有(you)公制螺(luo)(luo)紋及圓柱管螺(luo)(luo)紋兩(liang)種,在選用時應顧及原有(you)管道(dao)、管件(jian)采用的是哪種螺(luo)(luo)紋,以便舊件(jian)配換。

④. 在標注(zhu)管端(duan)螺紋時(shi)應注(zhu)意(yi):

PN320MPa的 DN6mm、DN10mm 管(guan)(guan)子和 PN220MPa 的 DN6mm、DN10mm、DN15mm管(guan)(guan)子,因受管(guan)(guan)子規格限制,只能采用G1/4in、G5/8in的圓柱管(guan)(guan)螺紋。

PN320MPa的DN15~65mm 管(guan)(guan)(guan)子(zi)(zi)和(he)PN220MPa的DN25~80mm管(guan)(guan)(guan)子(zi)(zi),可根據現場實際情況采用公制螺(luo)紋(wen)(wen)(wen)或圓柱管(guan)(guan)(guan)螺(luo)紋(wen)(wen)(wen)。也就(jiu)是說,在這些范圍內,兩(liang)種螺(luo)紋(wen)(wen)(wen)并用;PN320MPa的DN80mm或更(geng)大(da)的管(guan)(guan)(guan)子(zi)(zi)和(he)PN220MPa的DN100mm或更(geng)大(da)的管(guan)(guan)(guan)子(zi)(zi),管(guan)(guan)(guan)端螺(luo)紋(wen)(wen)(wen)只能用公制螺(luo)紋(wen)(wen)(wen)。

綜上所(suo)述,可列成表3-25。

公制螺(luo)紋為圓(yuan)根(gen)螺(luo)紋,外(wai)螺(luo)紋牙型槽底為圓(yuan)弧形(xing),圓(yuan)柱管(guan)螺(luo)紋為圓(yuan)角螺(luo)紋。管(guan)端(duan)螺(luo)紋的精度(du)等(deng)級為2a級,其技術要求(qiu)應符合《高(gao)壓(ya)管(guan)、管(guan)件(jian)及(ji)緊(jin)固件(jian)通用設計》中“H5-67”、“H6-67”及(ji)“H31-67”之規定。

⑤. 檢修工作中,在(zai)繪制好管段預制加工圖后(hou),應與原(yuan)有的高壓(ya)管道(dao)配管施(shi)工圖認真核對,一定要確認無誤后(hou)才能據以加工。

⑥. 在有把握的(de)(de)情況下,可以(yi)根據原有的(de)(de)高壓(ya)管(guan)(guan)(guan)(guan)(guan)道(dao)配管(guan)(guan)(guan)(guan)(guan)施工圖(tu)(tu)來繪制高壓(ya)管(guan)(guan)(guan)(guan)(guan)段的(de)(de)預制加工尺寸圖(tu)(tu),但封(feng)閉管(guan)(guan)(guan)(guan)(guan)段必須以(yi)現(xian)場實(shi)測(ce)數據的(de)(de)計算結果來繪制加工尺寸圖(tu)(tu)。封(feng)閉管(guan)(guan)(guan)(guan)(guan)段最(zui)好選(xuan)成容易測(ce)量(liang)的(de)(de)直管(guan)(guan)(guan)(guan)(guan)段,封(feng)閉管(guan)(guan)(guan)(guan)(guan)段的(de)(de)長(chang)度(du)最(zui)好實(shi)測(ce)。